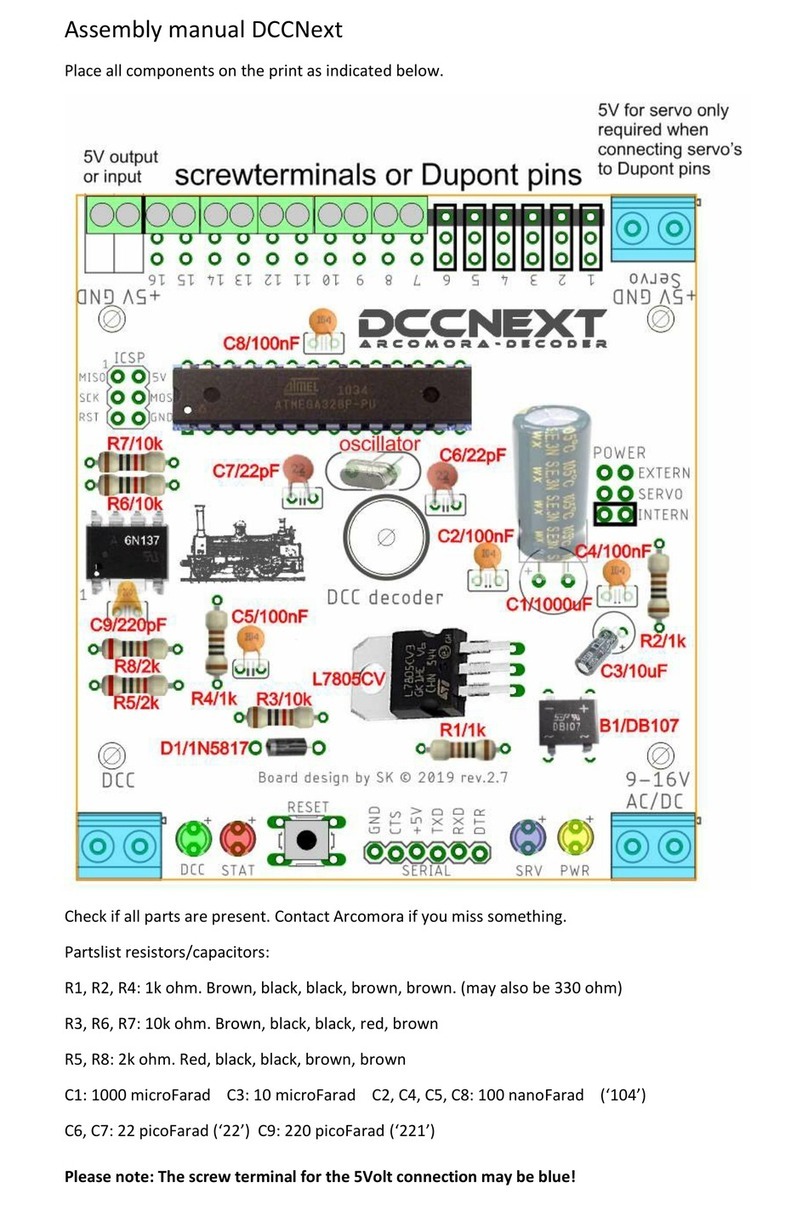

1. Place all resistors R1 to R8. Note the colour codes (there is no R5)

2. Place diodes D2, D3 and D5. Note the orientation.

3. Place both IC feet. Note the orientation. The cut-outs to the edge of the print.

Make sure that ALL pins protrude through the print. If placed incorrectly, that is no problem; pay

extra attention to the placement of the ICs.

4. Install the DB107 (D1) diode bridge and the L7805. Secure the L7805 with a nut and bolt.

Note the orientation of both components.

5. Install all capacitors except C4 (470 uF) and C8 (47 uF). C6 and C7 have an imprint ‘22’.

C6 has an imprint ‘221’or no imprint. The others (100 nF) have an imprint of ‘104’.

6. Place the oscillator and the reset switch. Place the insulation plate under the oscillator!

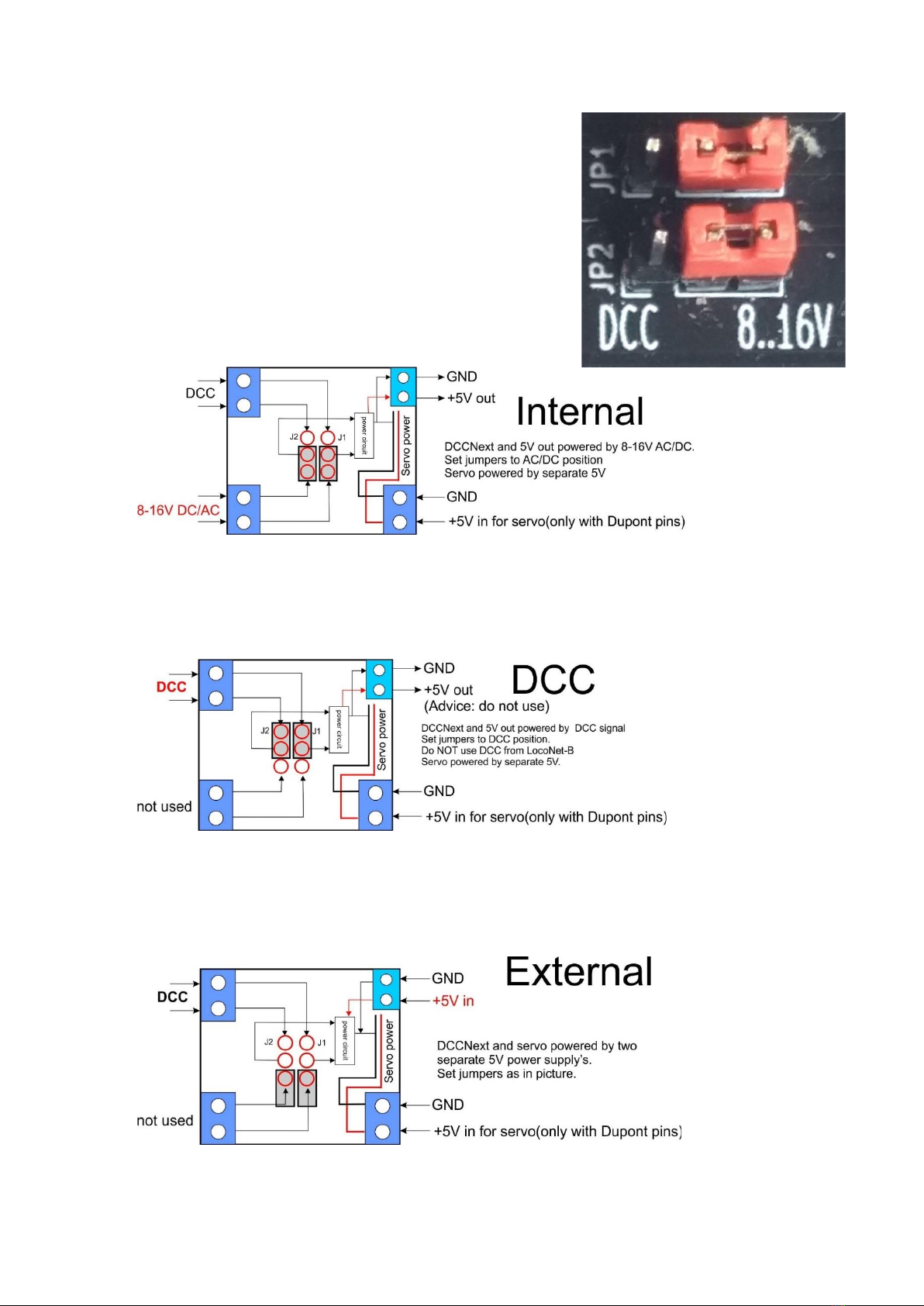

7. Cut 2 pieces of 3 Dupont pins and place them in the holes at the LM7805.

After soldering, place both jumpers over the pins at 8-16V or a DCC. See below for an explanation of

the power options

8. Place the 4 LEDs with the correct color. Note the orientation. The long leg is the plus (+).

9. Cut a piece of 6 Dupont pins and place this at Serial.

If desired, you can also solder the hooked Dupont pin as supplied with the USB interface. (See also

below for the USB connection options).

10. Only if you want to connect servos directly:

Cut pieces of 3 pins and solder them on the print. Do this preferably from port 1. Naturally you must

also configure the servos for these ports at Mardec. By using both 2-pole and 3-pole connections you

can make any number of 2 to 12 servos. Only one servo is not possible.

11. Slide the required number of terminal blocks together and solder them onto the print. If you have

not used servo pins, you must assemble them all. Place the terminals on the print first. Then turn it

over and push the print against the desk. Because of this the terminals are stuck and you can easily

solder.

NOTE: Use the small blue terminal for the 5Volt connection.

12. Install the 3 blue big screw terminals. Do this in the same

way as the green screw terminals.

13. Install capacitor C6. Note the orientation; the long leg is the

plus.

14. Install capacitor C4. Note the orientation. This can be done

in upright or lying position. Make sure that the capacitor lies

tight against the PCB when placed in the upright position and

the box is used.

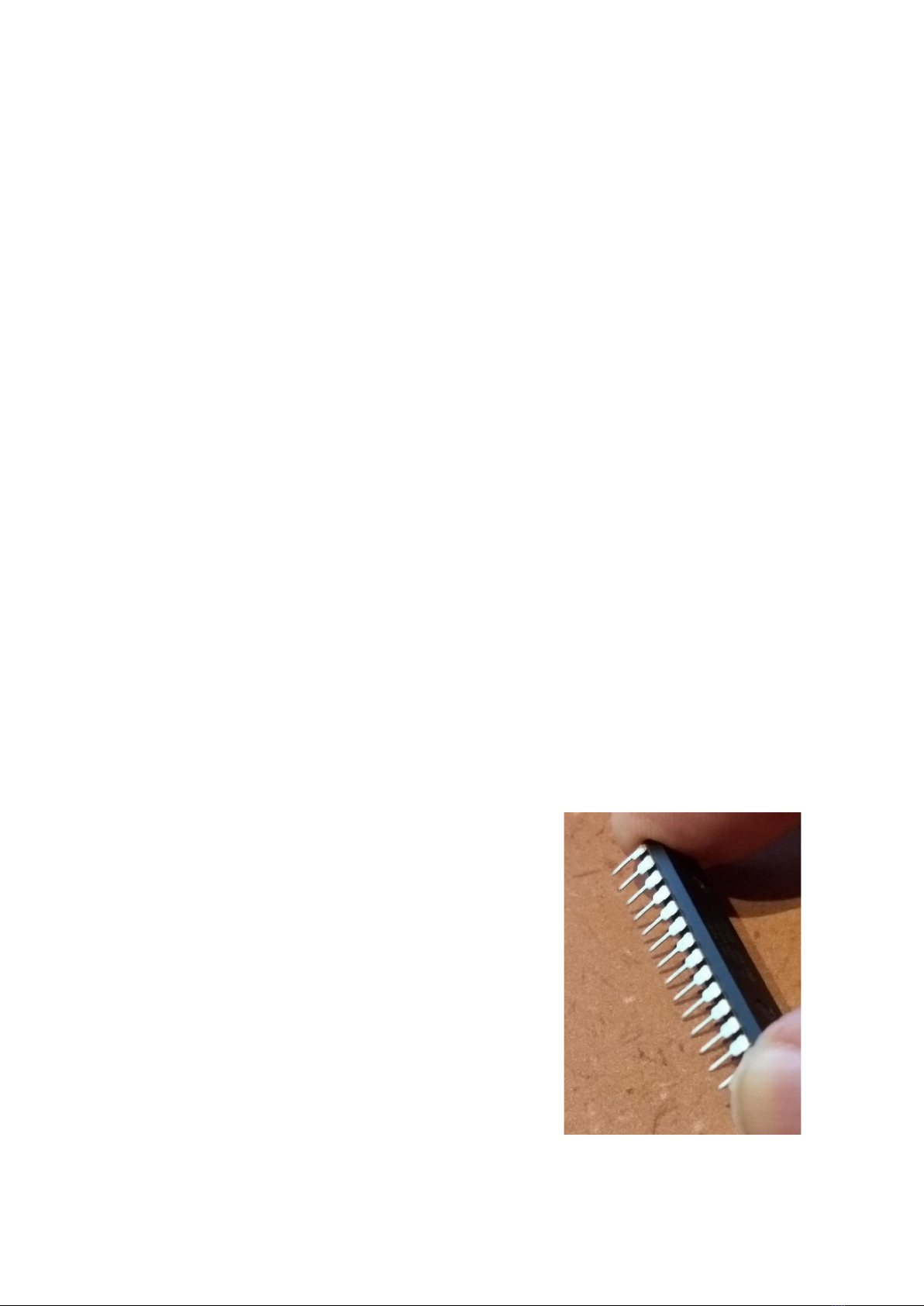

15. Install IC 6n137 and the ATMEGA328P processor. Usually

the legs are too far apart so that they do not fit well in the foot.

To bend them, place one side against the work surface and

push all legs at the same time a little to the right. Do this for

both sides.