1.3 Respirator Approvals and Limitations

The ARCONE®AIRPLUS®PAPR system as described in this instruction manual has been

approved by NIOS (National Institute for Occupational Safety and ealth) to the following

standard: NIOS 42 CFR Part 84 (USA, See Enclosed Approvals).

Special User Instructions

1. Improper respirator use may cause injury or death. Improper use may also cause certain

life-threatening delayed lung diseases. Regulations require the employer provide training to

the user on proper use, maintenance and limitations of ARCONE®AIRPLUS® PAPR system.

2. Each person using these respirators must first read and understand this instruction manual.

3. Before using ARCONE®AIRPLUS® PAPR system, be sure your employer has determined

airborne contaminant concentrations do not exceed those allowed by applicable OS A,

MS A, EPA, NIOS or ACGI regulations for powered air purifying respirators. Federal law

requires your employer measure and monitor airborne contaminant levels in the work area.

4. Failure to use components and replacement parts approved by NIOS for use with this

PAPR system voids NIOS approval of the entire respirator, invalidates all ARCONE®

AIRPLUS®PAPR warranties, and may cause death, lung disease or exposure to other

hazardous or life-threatening conditions.

5. Inspect all components of the ARCONE®AIRPLUS® PAPR system during cleaning and

before and after each use for signs of wear, tear or damage that might reduce the degree of

protection originally provided. Immediately replace worn or damaged components with

ARCONE®AIRPLUS® PAPR components approved by NIOS for use with this PAPR system.

6. DO NOT use the ARCONE®AIRPLUS® PAPR system in inadequately ventilated areas, where

oxygen is less than 19.5%, or in confined spaces such as tanks, small rooms, tunnels or

vessels unless the confined space is well-ventilated and contaminant concentrations are

below the recommendations for this system. The procedures for confined space entry,

operation and exit are defined in applicable regulations and standards, including

29 CFR 1910.146.

CAUTIONS AND LI ITATIONS

A- Not for use in atmospheres containing less than 19.5% oxygen.

B- Not for use in atmospheres immediately dangerous to life or health.

C- Do not exceed maximum use concentrations established by regulatory standards.

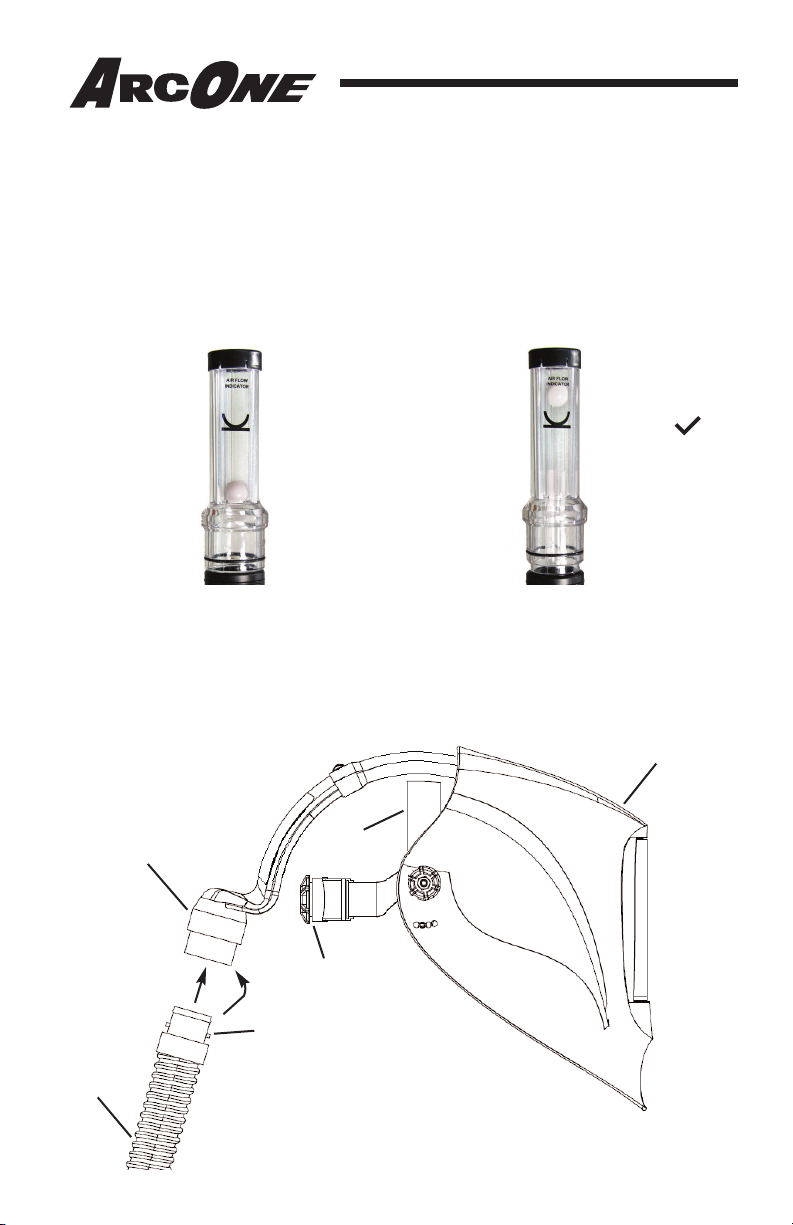

F- Do not use powered air-purifying respirators if airflow is less than four cfm (115 lpm) for

tight fitting facepieces or six cfm (170 lpm) for hoods and/or helmets.

I- Contains electrical parts that may cause an ignition in flammable or explosive atmospheres.

J- Failure to properly use and maintain this product could result in injury or death.

L- Follow the manufacturer's User's Instructions for changing cartridges and/or filters.

M- All approved respirators shall be selected, fitted, used, and maintained in accordance with

MS A, OS A, and other applicable regulations.

N- Never substitute, modify, add, or omit parts. Use only exact replacement parts in the

configuration as specified by the manufacturer.

O- Refer to User's Instructions, and/or maintenance manuals for information on use and

maintenance of these respirators.

P- NIOS does not evaluate respirators for use as surgical masks.

-5-