1

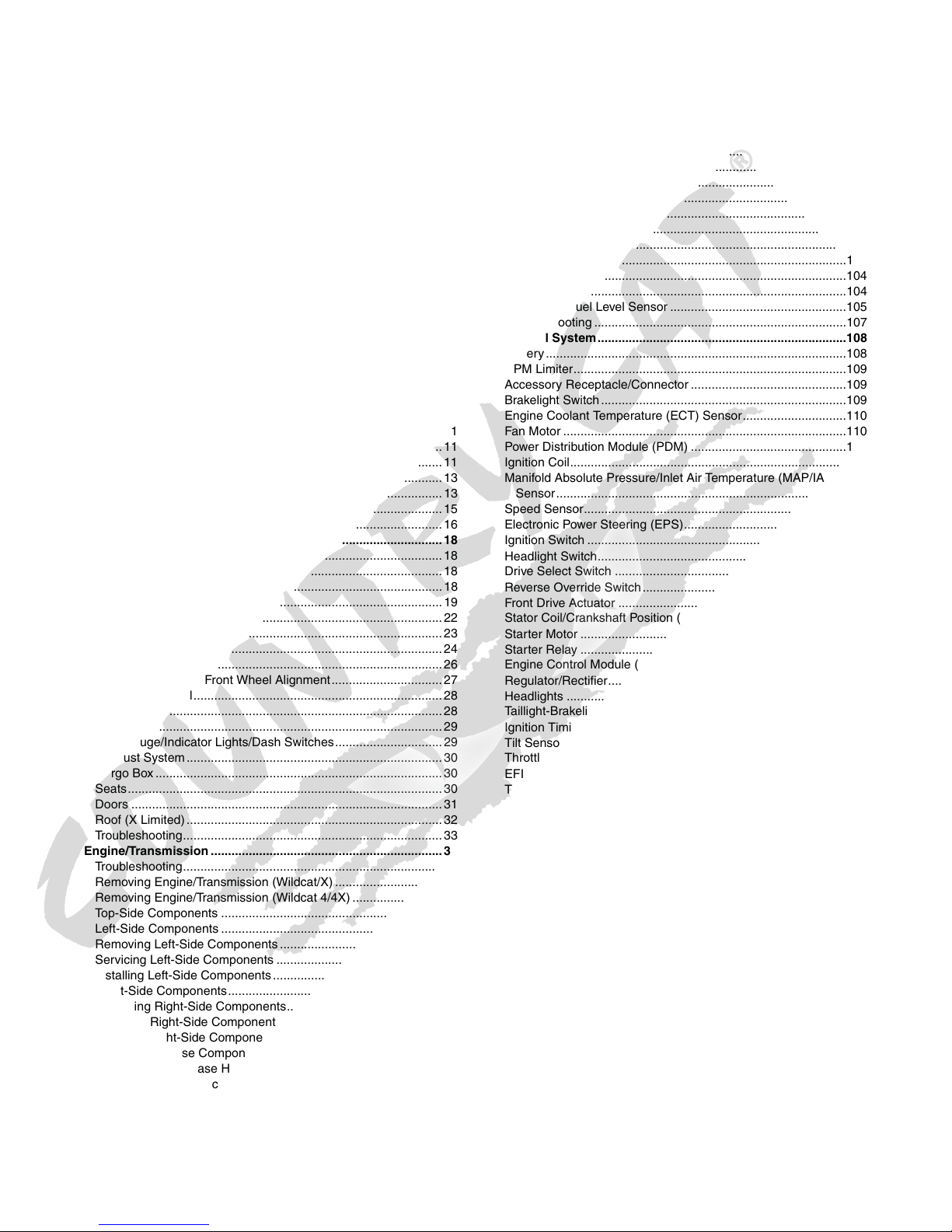

TABLE OF CONTENTS

General Information ....................................................................... 2

General Specifications .................................................................. 2

Torque Specifications.................................................................... 3

Torque Conversions (ft-lb/N-m)..................................................... 4

Drive Belt Break-In Procedure ...................................................... 4

Gasoline - Oil - Lubricant .............................................................. 4

Genuine Parts ............................................................................... 5

Preparation For Storage................................................................ 5

Preparation After Storage ............................................................. 5

Periodic Maintenance/Tune-Up ..................................................... 6

Periodic Maintenance Chart.......................................................... 6

Lubrication Points.......................................................................... 7

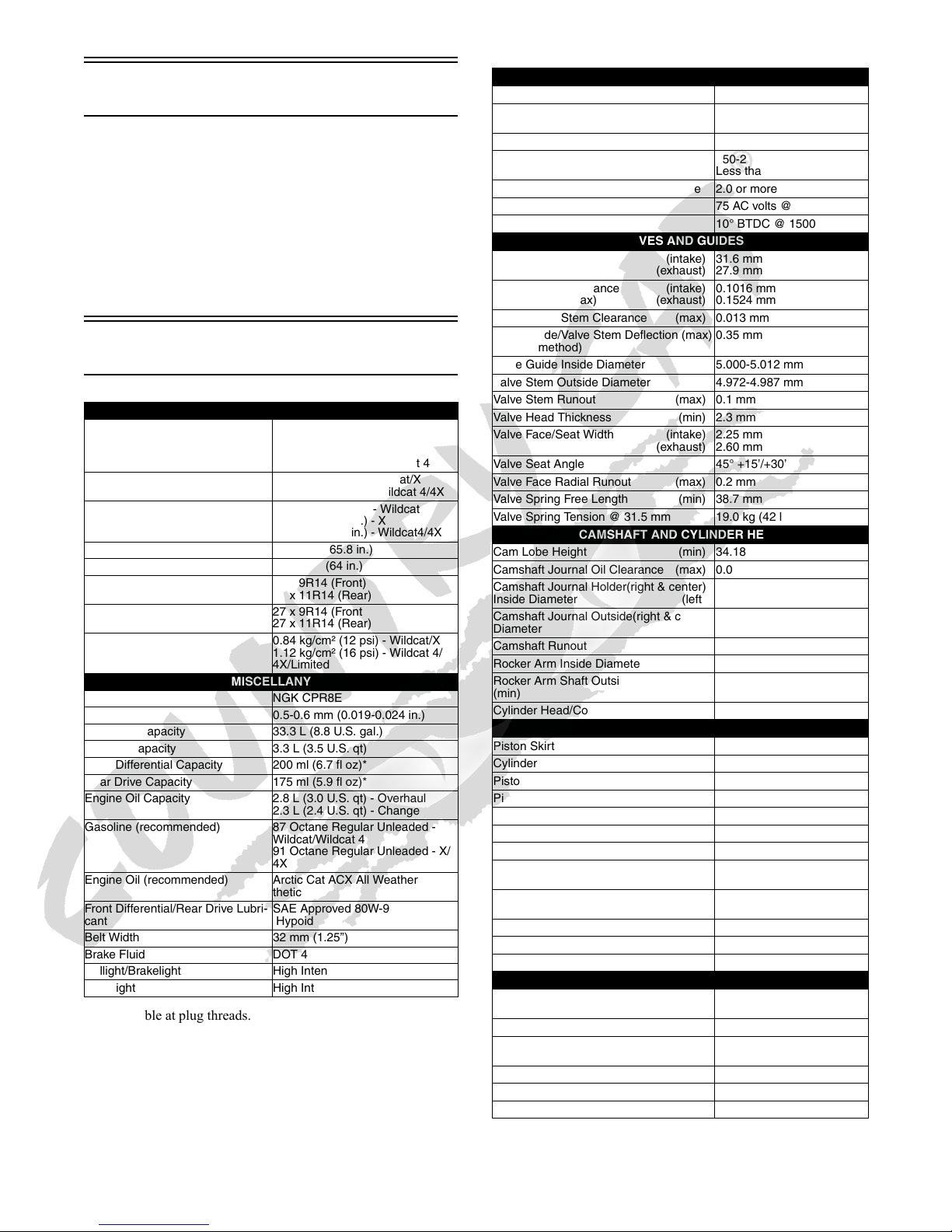

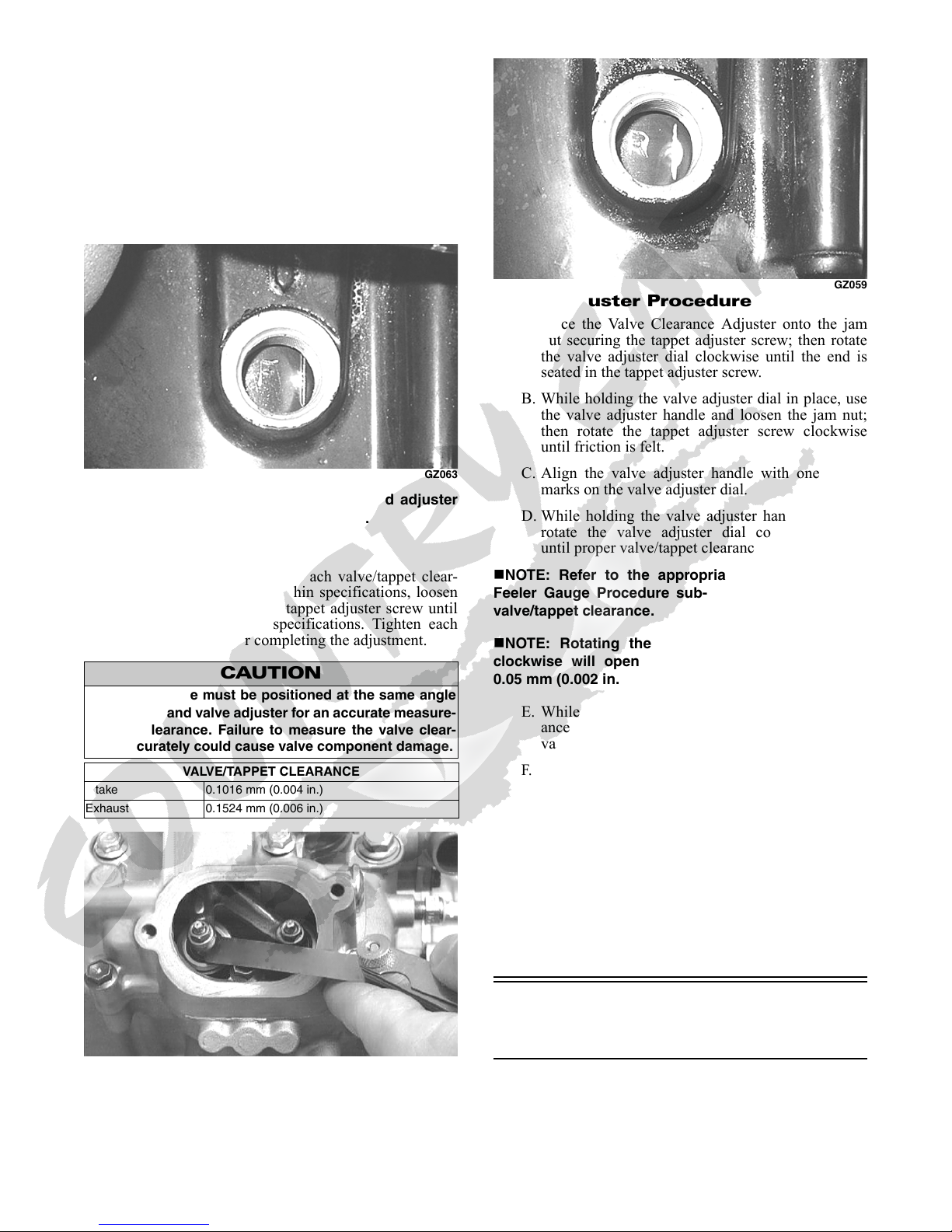

Air Filter......................................................................................... 7

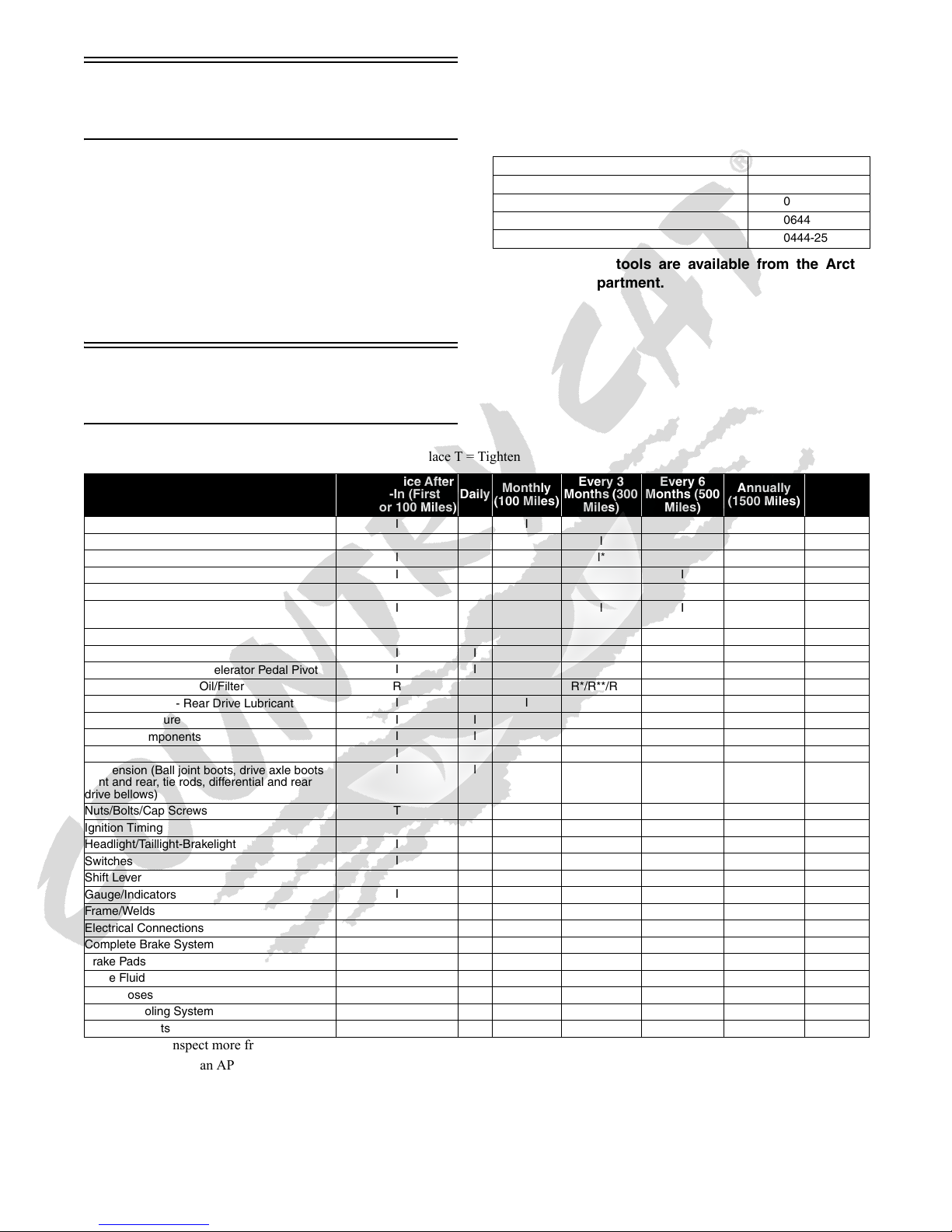

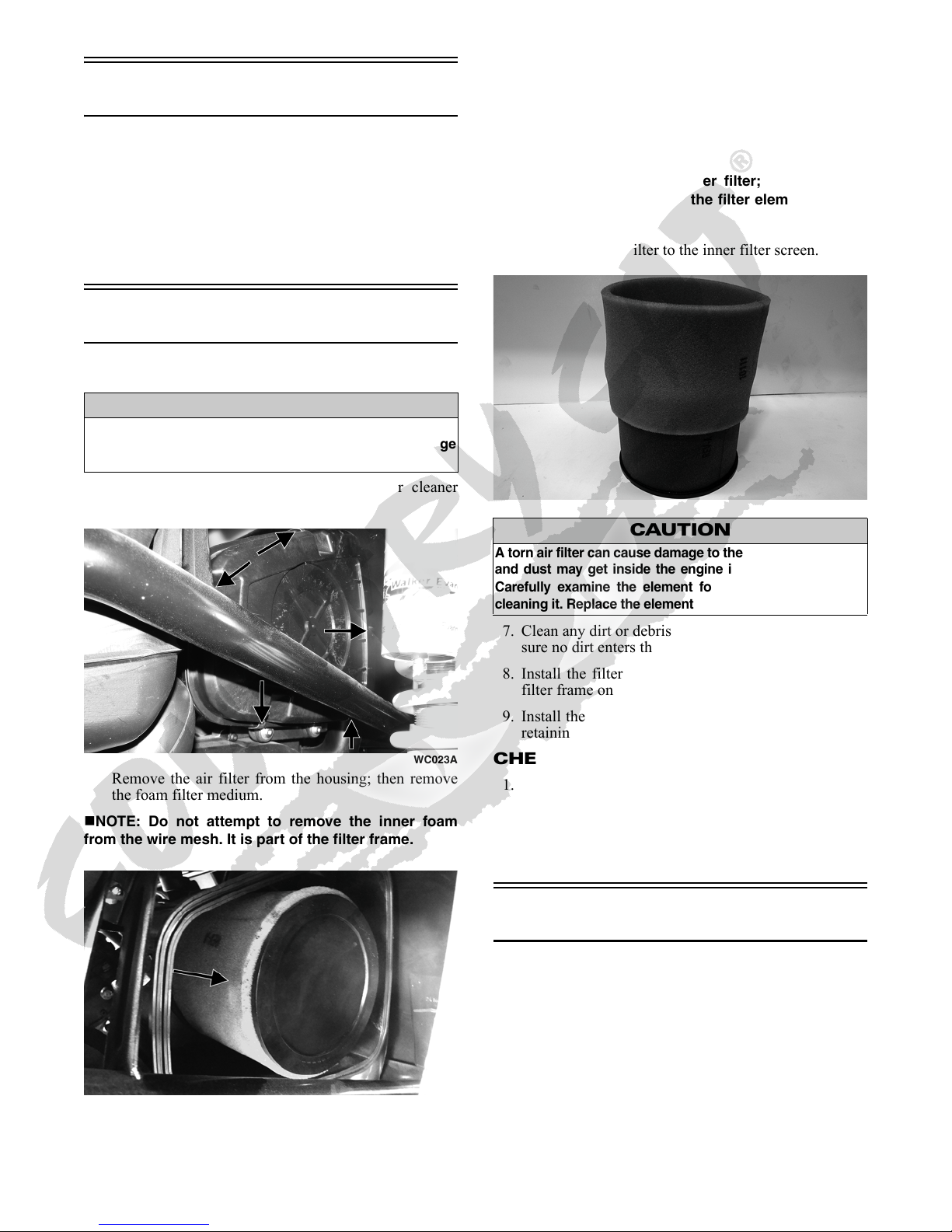

Valve/Tappet Clearance ................................................................ 7

Testing Engine Compression ........................................................ 8

Spark Plugs................................................................................... 9

Muffler/Spark Arrester................................................................... 9

Engine/Transmission Oil - Filter .................................................. 10

Front Differential - Rear Drive Lubricant ..................................... 11

Driveshaft/Coupling..................................................................... 11

Nuts/Bolts/Cap Screws ............................................................... 11

Headlight/Taillight-Brakelight....................................................... 11

Shift Lever/Shift Cable ................................................................ 13

Hydraulic Brake System.............................................................. 13

Burnishing Brake Pads................................................................ 15

Replacing V-Belt ......................................................................... 16

Steering/Frame/Controls ............................................................. 18

Hood ........................................................................................... 18

Front Bumper Assembly (X/4X/Limited)...................................... 18

Rear Body Panel......................................................................... 18

Electronic Power Steering (EPS) ................................................ 19

Rack and Pinion Assembly ......................................................... 22

Steering Wheel ........................................................................... 23

Steering Shaft ............................................................................. 24

Steering Knuckles ....................................................................... 26

Checking/Adjusting Front Wheel Alignment................................ 27

Accelerator Pedal ........................................................................ 28

Shift Lever ................................................................................... 28

Shift Cable .................................................................................. 29

LCD Gauge/Indicator Lights/Dash Switches............................... 29

Exhaust System .......................................................................... 30

Cargo Box ................................................................................... 30

Seats........................................................................................... 30

Doors .......................................................................................... 31

Roof (X Limited) .......................................................................... 32

Troubleshooting........................................................................... 33

Engine/Transmission ................................................................... 34

Troubleshooting........................................................................... 35

Removing Engine/Transmission (Wildcat/X) ............................... 37

Removing Engine/Transmission (Wildcat 4/4X) .......................... 41

Top-Side Components ................................................................ 46

Left-Side Components ................................................................ 63

Removing Left-Side Components ............................................... 63

Servicing Left-Side Components ................................................ 66

Installing Left-Side Components ................................................. 68

Right-Side Components.............................................................. 70

Removing Right-Side Components............................................. 70

Servicing Right-Side Components.............................................. 71

Installing Right-Side Components............................................... 77

Center Crankcase Components.................................................. 79

Separating Crankcase Halves..................................................... 79

Disassembling Crankcase Half ................................................... 80

Servicing Center Crankcase Components.................................. 82

Assembling Crankcase Half ........................................................ 89

Joining Crankcase Halves........................................................... 90

Installing Engine/Transmission (Wildcat/X) ................................. 92

Installing Engine/Transmission (Wildcat 4/4X) ............................ 95

Fuel/Lubrication/Cooling .............................................................99

Throttle Body ...............................................................................99

Gas Tank ...................................................................................100

Gas/Vent Hoses.........................................................................101

Oil Filter/Oil Pump .....................................................................101

Oil Cooler ..................................................................................102

Liquid Cooling System...............................................................102

Radiator.....................................................................................102

Thermostat ................................................................................103

Fans...........................................................................................104

Water Pump...............................................................................104

Fuel Pump/Fuel Level Sensor ...................................................105

Troubleshooting .........................................................................107

Electrical System........................................................................108

Battery .......................................................................................108

RPM Limiter...............................................................................109

Accessory Receptacle/Connector .............................................109

Brakelight Switch .......................................................................109

Engine Coolant Temperature (ECT) Sensor..............................110

Fan Motor ..................................................................................110

Power Distribution Module (PDM) .............................................110

Ignition Coil................................................................................111

Manifold Absolute Pressure/Inlet Air Temperature (MAP/IAT)

Sensor....................................................................................111

Speed Sensor............................................................................112

Electronic Power Steering (EPS)...............................................112

Ignition Switch ...........................................................................114

Headlight Switch........................................................................114

Drive Select Switch ...................................................................114

Reverse Override Switch ...........................................................115

Front Drive Actuator ..................................................................115

Stator Coil/Crankshaft Position (CKP) Sensor ..........................115

Starter Motor .............................................................................116

Starter Relay .............................................................................117

Engine Control Module (ECM) ..................................................117

Regulator/Rectifier.....................................................................117

Headlights .................................................................................118

Taillight-Brakelight .....................................................................118

Ignition Timing ...........................................................................118

Tilt Sensor .................................................................................118

Throttle Position Sensor (TPS)..................................................119

EFI Diagnostic System ..............................................................120

Troubleshooting .........................................................................125

Drive and Brake Systems ..........................................................126

Front Drive Actuator ..................................................................126

Front Differential ........................................................................127

Driveshaft (Wildcat 4/4X)...........................................................139

Drive Axles ................................................................................142

Rear Gear Case ........................................................................145

Hub............................................................................................151

Hydraulic Brake Caliper (Wildcat)..............................................153

Hydraulic Brake Caliper (X/Wildcat 4/4X)..................................156

Master Cylinder Assembly.........................................................159

Troubleshooting Drive System...................................................161

Troubleshooting Brake System..................................................161

Suspension .................................................................................162

Shock Absorbers .......................................................................162

Shock Absorbers (Limited) .......................................................176

Front A-Arms .............................................................................178

Rear Trailing Arms.....................................................................181

Wheels and Tires ......................................................................183

Troubleshooting .........................................................................184