1-4

** w/Red Loctite #271

*** w/Green Loctite #270

Torque Conversions

(ft-lb/N-m)

Break-In Procedure

A new vehicle and an overhauled engine require a

“break-in” period. The first 10 hours (or 200 miles) are

most critical to the life of this vehicle. Proper operation

during this break-in period will help assure maximum life

and performance from the vehicle.

During the first 10 hours (or 200 miles) of operation,

always use less than 1/2 throttle. Varying the engine

RPM during the break-in period allows the components

to “load” (aiding the mating process) and then “unload”

(allowing components to cool). Although it is essential to

place some stress on the engine components during

break-in, care should be taken not to overload the engine

too often. Do not pull a trailer or carry heavy loads dur-

ing the 10-hour break-in period.

When the engine starts, allow it to warm up properly. Idle

the engine several minutes until the engine has reached

normal operating temperature. Do not idle the engine for

excessively long periods of time.

ENGINE/TRANSMISSION - H2

Part Part Bolted To Torque

ft-lb N-m

Clutch Shoe** Crankshaft 221 300

Clutch Cover/Housing

Assembly

Crankcase 8 11

Lower Crankcase Cover

(6 mm)

Crankcase 8 11

Lower Crankcase Cover

(8 mm)

Crankcase 20 27

Crankcase Half Crankcase Half 8 11

Cylinder Head (Cap Screw) Crankcase 38 52

Cylinder Head Nut (6 mm) Cylinder 8 11

Cylinder Head Nut (8 mm) Cylinder 18 24

Valve Cover Cylinder Head 8.5 11.5

Driven Pulley Nut** Driveshaft 80 109

Movable Drive Face Nut** Driveshaft 165 224

Ground Wire Engine 8 11

Magneto Cover Crankcase 8 11

Tappet Cover Valve Cover 9 12

Crankshaft Spacer Crankshaft 28 38

Oil Pump Drive Gear** Crank Balancer Shaft 62 84

Output Yoke Nut** Output Shaft 74 100

Outer Magneto Cover Magneto Cover 8 11

Rotor/Flywheel Nut** Crankshaft 105 143

Cam Sprocket** Camshaft 11 15

CVT Cover Crankcase 8 11

Secondary Drive Gear Nut** Secondary Drive Output

Shaft

74 100

Oil Filter Cover Crankcase 8 11

Speed Sensor Housing Crankcase 8 11

Shift Cam Stopper Crankcase 8 11

Shift Cam Stopper Spring Shift Cam Stopper 8 11

Shift Cam Plate Shift Cam Shaft 8 11

Shifter Housing Crankcase 8 11

Starter Motor Crankcase 8 11

V-Belt Cover Crankcase 8 11

Oil Pump Cover** Crankcase 8 11

Oil Strainer Cap Crankcase 8 11

Stator Coil* Magneto Cover 8.5 11.5

Intake Boot Clamp Intake Boot 30

in.-lb

3.4

Starter One-Way Clutch** Flywheel 26 35

DRIVE TRAIN COMPONENTS

Rear Differential/Gear Case Frame 38 48

Drive Coupler (Front) Drive Flange 40 54

Front Engine Mounting Bracket Frame 45 61

Rear Engine Mounting Bracket Frame 45 61

Engine Mounting Through-Bolt Frame 40 54

Front Differential Frame/Differential Bracket 38 52

Rear Output Flange Rear U-Joint Flange 40 54

Input Shaft Assembly Gear Case Housing 23 31

Pinion Housing Differential Housing 23 31

Thrust Button Gear Case Cover 8 11

Differential Housing Cover*** Differential Housing 23 31

Drive Bevel Gear Nut*** Shaft 87 118

Lock Collar Differential Housing 125 170

Hub Nut Front/Rear Shaft/Axle (min) 200 272

Oil Drain Plug Front Differential - Rear

Drive

45

in.-lb

5

Oil Fill Plug Front Differential - Rear

Drive

16 22

Oil Drain Plug Engine 16 22

Wheel (Aluminum) Hub 80 108

Wheel (Steel) Hub 45 61

Front Input Drive Flange Front U-Joint 20 27

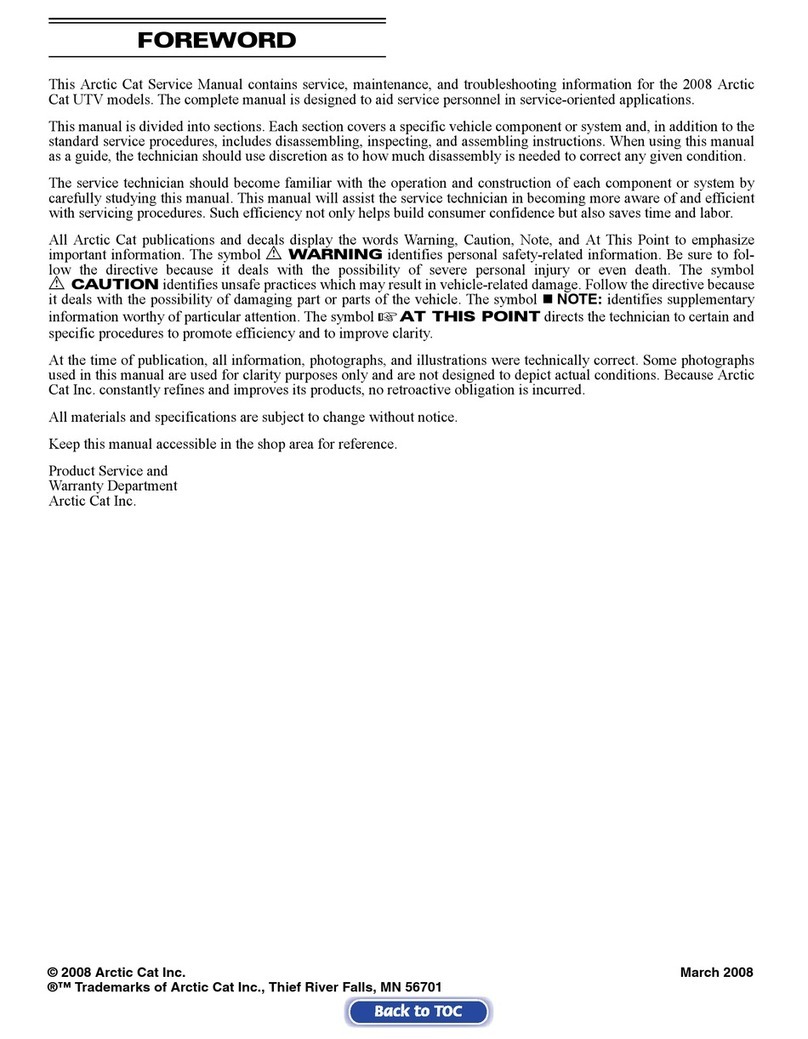

ft-lb N-m ft-lb N-m ft-lb N-m ft-lb N-m

11.4 26 35.4 51 69.4 76 103.4

22.7 27 36.7 52 70.7 77 104.7

34.1 28 38.1 53 72.1 78 106.1

45.4 29 39.4 54 73.4 79 107.4

56.8 30 40.8 55 74.8 80 108.8

68.2 31 42.2 56 76.2 81 110.2

79.5 32 43.5 57 77.5 82 111.5

810.9 33 44.9 58 78.9 83 112.9

912.2 34 46.2 59 80.2 84 114.2

10 13.6 35 47.6 60 81.6 85 115.6

11 15 36 49 61 83 86 117

12 16.3 37 50.3 62 84.3 87 118.3

13 17.7 38 51.7 63 85.7 88 119.7

14 19 39 53 64 87 89 121

15 20.4 40 54.4 65 88.4 90 122.4

16 21.8 41 55.8 66 89.8 91 123.8

17 23.1 42 57.1 67 91.1 92 125.1

18 24.5 43 58.5 68 92.5 93 126.5

19 25.8 44 59.8 69 93.8 94 127.8

20 27.2 45 61.2 70 95.2 95 129.2

21 28.6 46 62.6 71 96.6 96 130.6

22 29.9 47 63.9 72 97.9 97 131.9

23 31.3 48 65.3 73 99.3 98 133.3

24 32.6 49 66.6 74 100.6 99 134.6

25 34 50 68 75 102 100 136