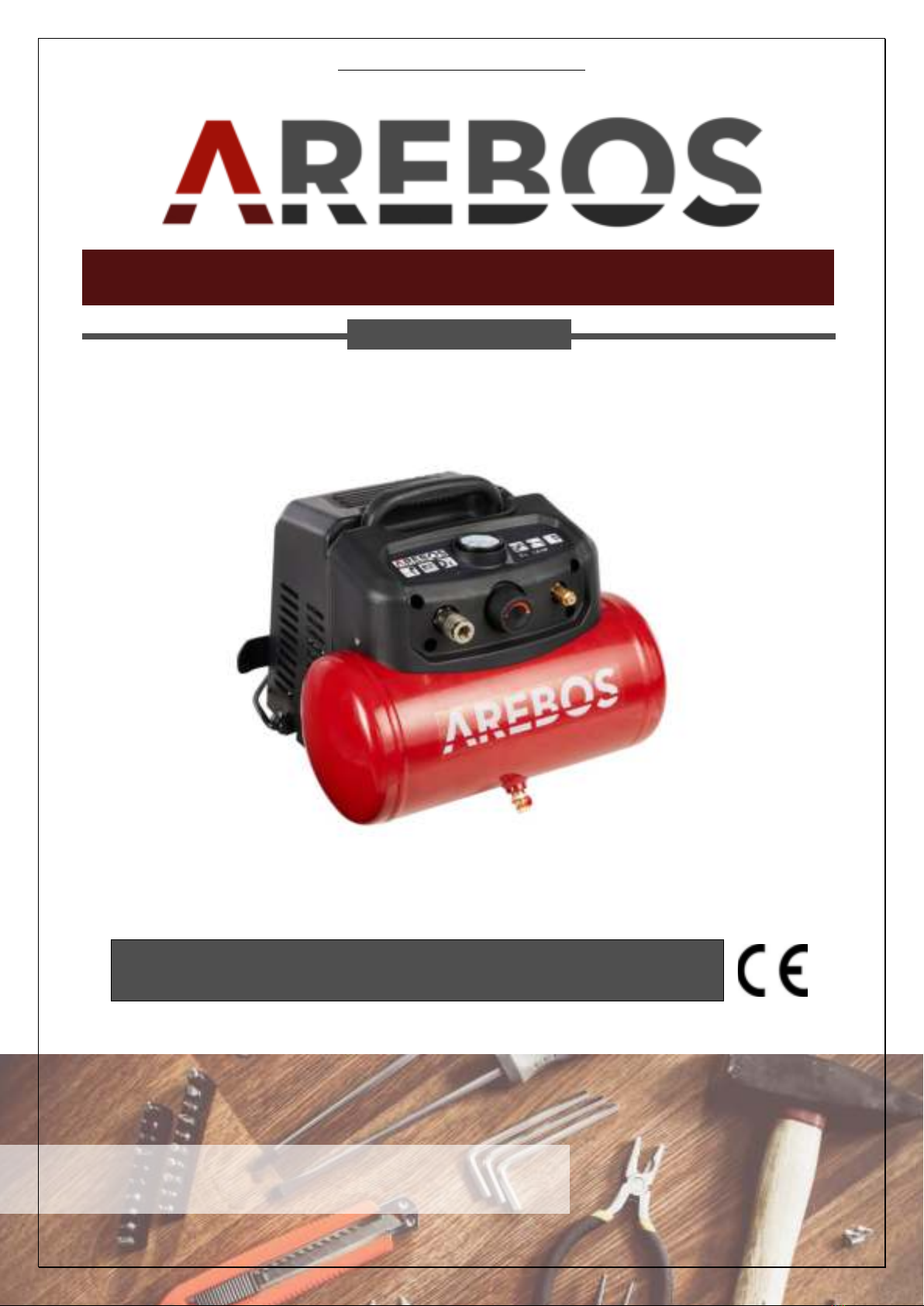

User’s Manual –AREBOS Air Compressor 6 L

6

•Danger of burning! Compressors and lines reach high temperatures during operation.

Touching leads to burns.

- Do not touch the compressor and lines during operation to avoid burns.

- Be careful when working.

•The gases or vapors sucked in by the compressor must be kept free from any admixtures that

could cause fires or explosions in the compressor.

•Wear safety glasses and respiratory protection when working with the blow gun. Foreign

objects, blown-off parts, and swirled-up dust can easily cause personal injury and damage to

health through inhalation. Dust-raising work should be carried out outdoors.

•Warning: All hoses and fittings of road-going compressors must be suitable for use on

construction sites at the maximum permissible pressure.

•Avoid heavy loads on the piping system by using flexible hose connections to prevent kinking.

1.4 Safety instructions for the compressor

•Danger! For your own safety, operate the compressor only after reading the safety

instructions.

•Risk of explosion! If you operate the compressor in an unsuitable, poorly ventilated place, in

an unsuitable ambient temperature, or in a room containing dusts, acids, vapors, or

flammable gases, there is a risk of explosion.

- The compressor must not be operated or stored in a room containing dusts, acids, vapors or

flammable gases. He can explode.

- Keep away easily flammable substances from the compressor.

- Keep the gases or vapors sucked in from the compressor free of any impurities that could

cause fires and explosions in the compressor.

- Operate the compressor only at an ambient temperature of at least 5°C and at a maximum

of 40°C. At temperatures below 5°C, the motor startup is endangered by stiffness.

- Ensure that the ambient temperature in a closed working environment is not higher than

25°C to ensure proper operation of the compressor while maintaining full air charge.

- Only operate the compressor in well-ventilated areas.

- Do not spray water or flammable liquids on the compressor.

•Risk of injury! The compressor's compressed air tank is under pressure during operation and

in the non-vented state. If the compressor is damaged, connections are loosened or

unsuitable or damaged lines are used, pressure may be released.

- The compressor must not be operated if the compressed air tank has defects that endanger

the operator or third parties.

- Check the compressed air tank for rust and damage before each use. If damage is found,

contact a qualified specialist immediately.

- Do not switch on the compressor before the compressed air hose is connected.

- Never drill holes in the compressed air tank, do not weld or deform it.

- Never operate the compressor if the compressed air tank is damaged or deformed.

- Ensure that the compressed air tank is always vented before releasing connections or

connecting or removing pneumatic tools.

- Make sure that you only use compressed air lines for compressed air that are suitable for a

maximum pressure that matches the device.

- Use a compressed air hose with hose protection when working with a pressure of 7 bar or

more.

- Do not try to repair damaged wires, but replace them.

- Never transport the compressor when the compressed air tank is pressurized.

•Risk of electric shock! Faulty electrical installation or excessive mains voltage can lead to

electric shocks.

- Only connect the compressor if the mains voltage of the socket agrees with the