INSTALLATION AND USE INSTRUCTIONS

TRANSPORT

cover the hydraulic connections•

lift the hydraulic plastic parts without mechanical stress•

for transport on irregular roads, cushion the bumps with suitable support plane•

blows and impacts may damage parts that are important for the machine operation and safety•

STORAGE INSTRUCTIONS

When is necessari to store the dampeners before installation don’t remove it from the original packaged. The packa-•

ged dampeners must be stored lifted from ground level, the ambient must be close, clean and dry.

If at the receipt of the dampeners package seems damaged is necessary to free the dumpner in order to check its•

integry and to store a new package

The place where the dampeners is stored must be closed with an ambient temperature not lower than –5°C and•

not higher than 40°C, the air humidity rate not higher than 80%, the package dampeners mustn’t received shock,

vibrations and loads rising above.

INSTALLATION

clean the plant before connecting the pump and dampener•

make sure that no foreign bodies are left in the dampener. Remove safety caps on the hydraulic connections.•

make sure that all of the dampener’s screws are well tightened•

position and secure the dampener horizontally•

place the pump and the dampener nearest at the suction point•

only ttings with cylindrical gas threads in materials compatible with both the uid to be pumped and the dampener’s •

construction materials must be used for the connections to the dampener’s collectors

pneumatic supply to the dampener must be made using ltered, died and not lubricated oil free at a pressure of not •

less than 2 bars and not more than 7 bars.

can use the same pneumatic supply of the pump•

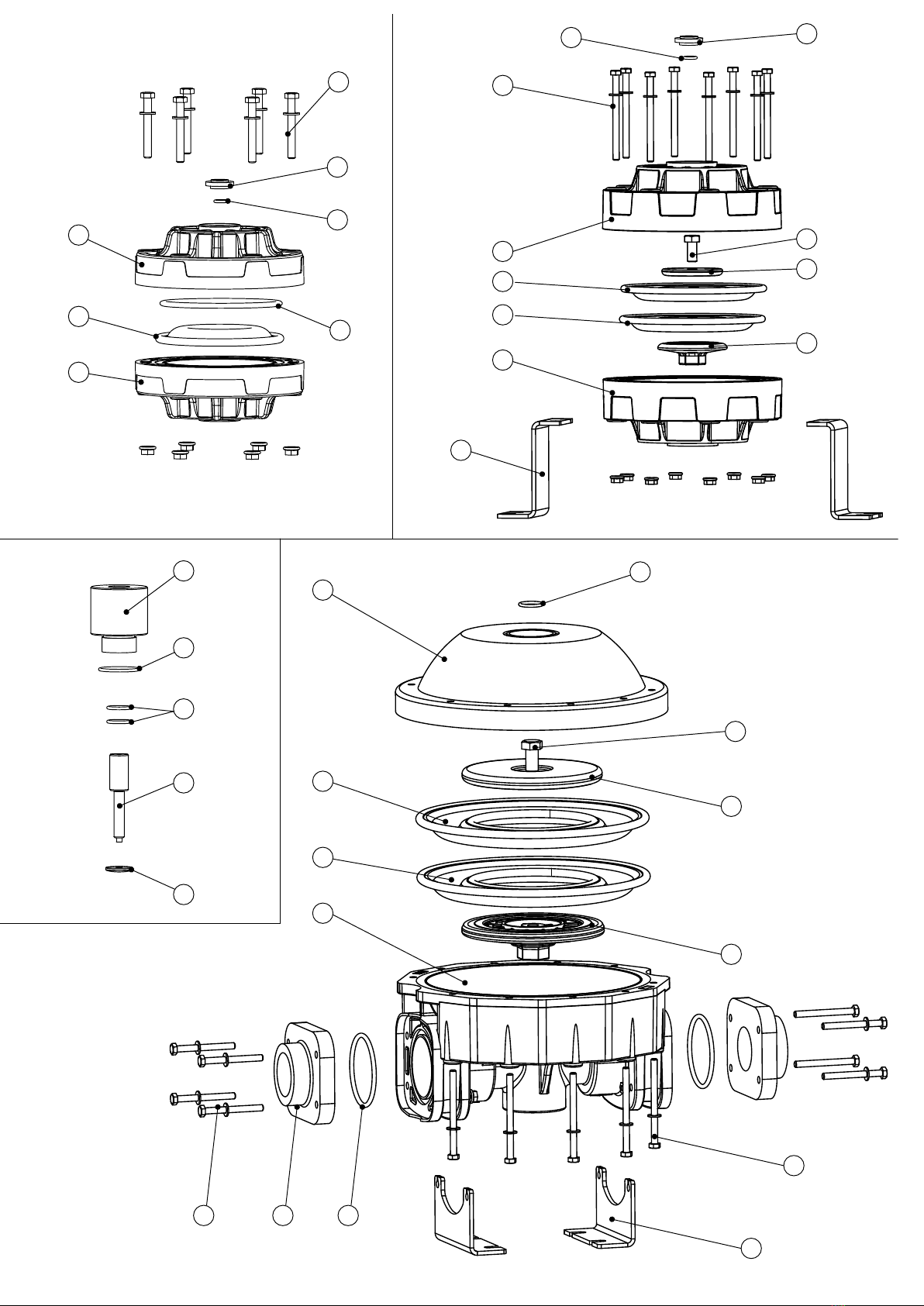

follow the instructions indicated in the following diagram:

1. YES: use exible pipes reinforced with rigid spiral to connect the hydraulic circuit of the pump. Rigid piping may cau-

se strong vibrations and manifolds breaking. Do not use pipes with nominal diameter smaller than the diameter of the

pump connections. For negative installations and/or viscous uids use pipes with greater diameter related to the nominal

diameter of the pump

2. YES: install and connect the pipe downstream from the pulsation dampener. Its diameter must never be smaller than

the connection. The pipe downstream from the dampener can be rigid and made from material compatible with the uid

to be pumped

3. YES: pipe for safety discharge; if the diaphragms are completely torn, the uid may enter the air circuit damage it,

and be discharged through the exhaust port. It is therefore necessary that the air exhaust be conveyed by pipes into a

piping reaching a safe area

4. YES: pipe anchoring; the piping must be sufciently strong to avoid deformation and must never weigh down on the

dampener in any way or viceversa

5. YES: shut-off valve of the same diameter as the pump inlet (never smaller) to intercept the uid correctly in case of

spills and/or when servicing the pump

6. YES: horizzontal place

7. NO: vertical place

8. YES: carry out effective grounding using a suitable size of cable on each pump casing to discharge static currents

9. YES: dampener anchoring

10.YES: trap

11.YES: pressure regulator with gauge

12.YES: check valves on the air supply piping to prevent the pumped liquid from entering the pneumatic circuit if the

diaphragms are broken is forbidden

13.YES: three-way valve for stop the dampener

14.YES: ow regulator

ensure drainage of uids which may come out of the dampener•

x the dampener avoid that the pipe weight down up it•

arrange for enough room around the dampener for the movements of an operator•

inform about the presence of aggressive uid with suitable coloured labels in accordance with the related standard•