EN

2

IMPORTANT!

Please read before installation

This air conditioning system meets strict safety and operating standards.

For the installer or service person, it is important to install or service the system so that it operates safely and efficiently.

operation, you must:

• Carefully read this instruction booklet before beginning.

• Follow each installation or repair step exactly as shown.

• Observe all local, state and national electrical codes.

• Pay close attention to all warning and caution notices given in this manual.

•The unit must be supplied with a dedicated electrical line.

This symbol refers to a hazard or unsafe practice which can result in severe personal injury or death.

This symbol refers to a hazard or unsafe practice which can result in personal injury or product or property damage.

Recommendations

• The personnel responsible for receiving the unit must conduct a visual inspection in order to identify all damage to

which the unit may have been subjected during transport: refrigerating circuit, electrical cabinet, chassis and cabinet.

If necessary, get help

These instructions are all you need for most installation sites and maintenance conditions.

If you require help for a special problem, contact our sale/service outlet or your certified dealer for additional instructions.

In case of improper installation

The manufacturer shall in no way be responsible for improper installation or maintenance service, including failure to

follow the instructions in this document.

SPECIAL PRECAUTIONS

• During installation, connect before the refrigerant system and then the wiring one; proceed in the reverse orden when

removing the units.

WARNING

CAUTION

CONTENTS

1 - Installation site selection.................................................................4

2 - System wiring diagram ...................................................................4

3 - Wires’ length, size and delayed fuse............................................4

4 - Additional material required for installation (not supplied).............5

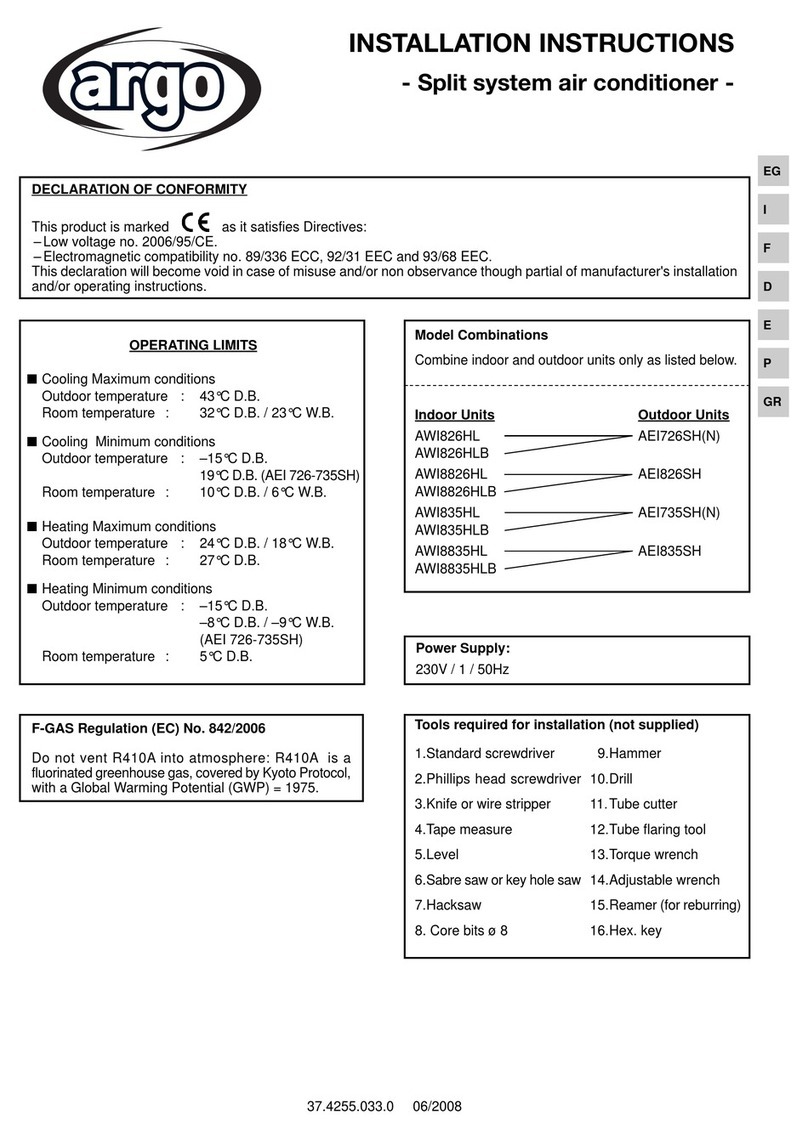

5 - Operating limits...............................................................................5

6 - Dimensions, weight and refrigerant connections ...........................5

7 - Accessories.....................................................................................5

8 - Tools required for installation (not supplied) ..................................5

9 - Installation procedure .....................................................................6

10 - Remote control unit installation......................................................9

11 - Wired controller installation (if present) ........................................10

12 - Pump Down ..................................................................................11

13 - Outdoor/indoor unit refrigerant circuit address............................12

14 - Match between remote controller and indoor unit.......................14

15 - Home Automation kit....................................................................15

16 - Jumper..........................................................................................15

17 - Parameters table...........................................................................16

18 - Electrical wiring diagram...............................................................17