Contents Page

1. Introduction................................................................................................................. 3

2. SAFETY FIRST! Important Safety Information's ........................................................ 4

3. Technical Specifications.............................................................................................. 5

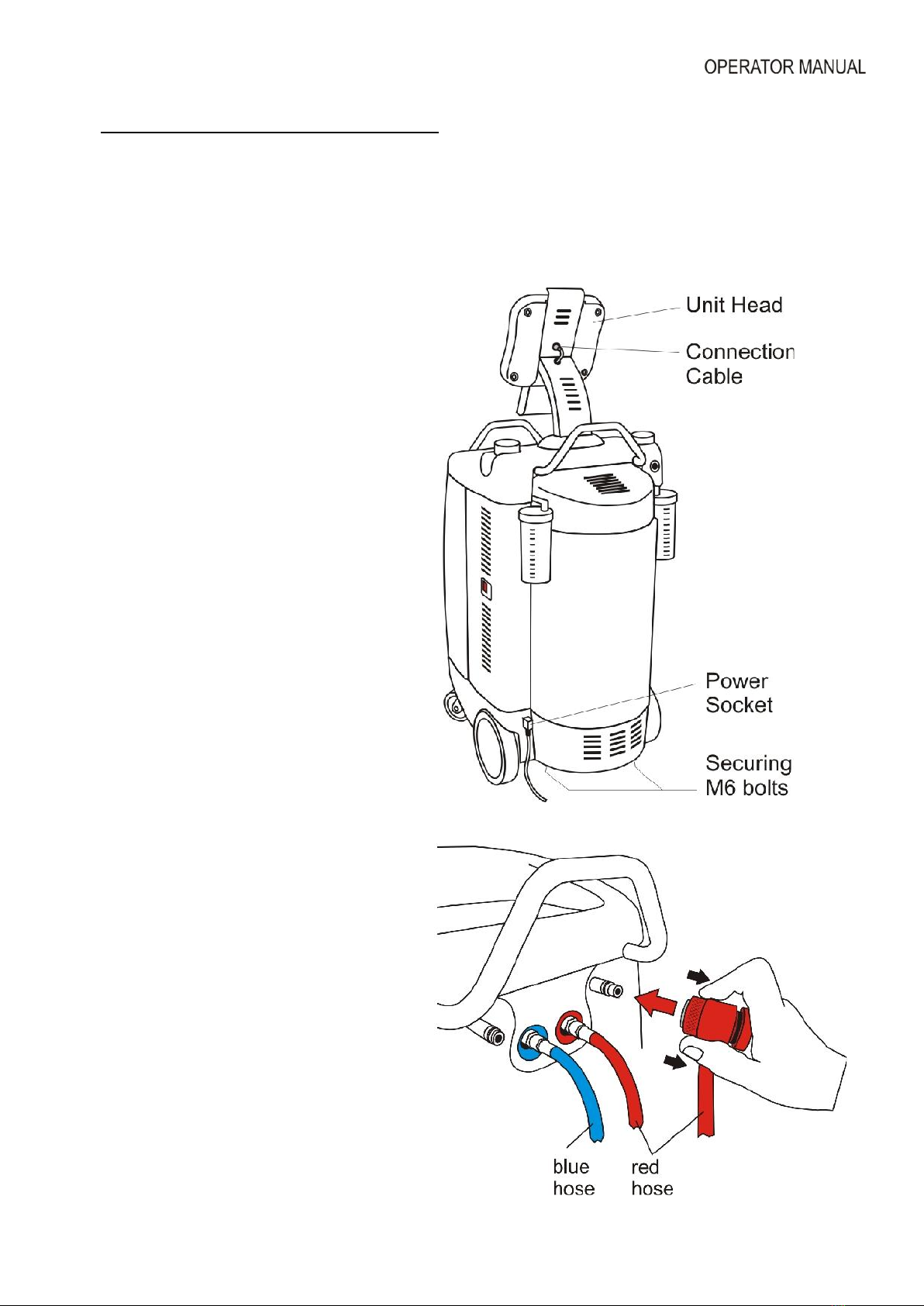

4. Preparing the Machine for the First Use ..................................................................... 6

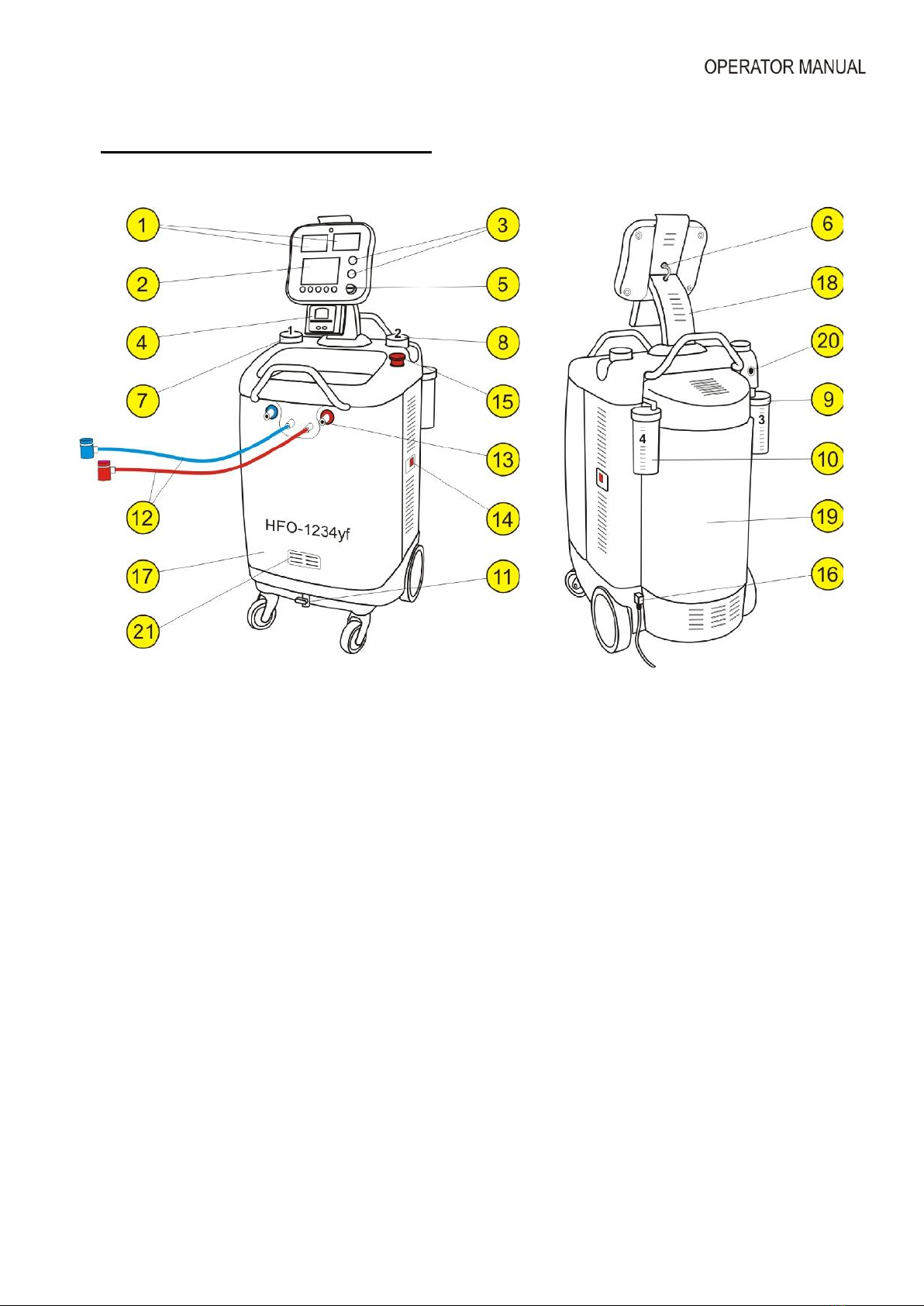

5. Main Components & Features .................................................................................... 7

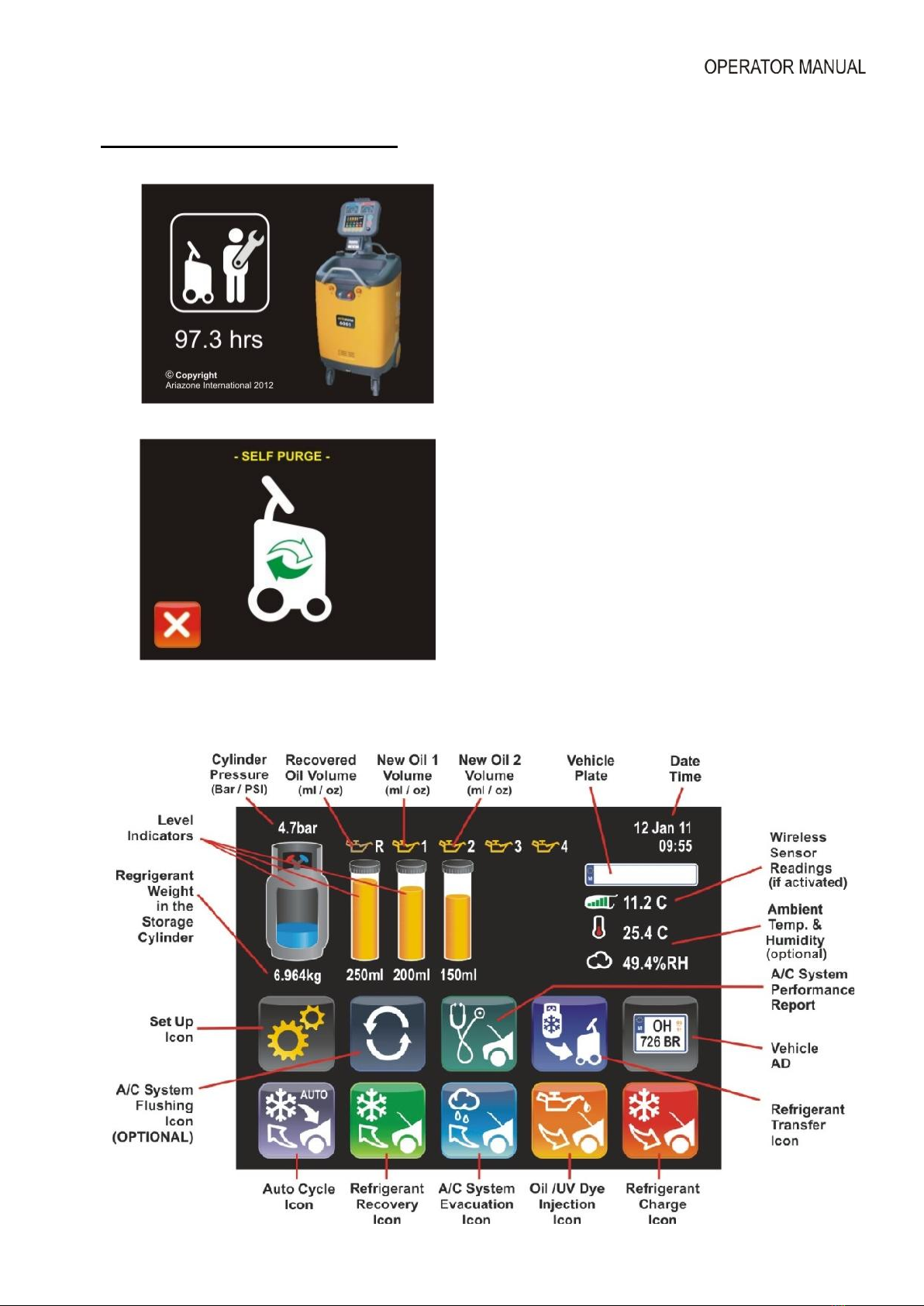

6. Switching ON the Machine .......................................................................................... 9

7. Icons and their meaning .............................................................................................10

7.1. Key icons………………………………………………………………………….10

7.2 Warning icons …………………………………………………………………….12

8. Printer Set Up .............................................................................................................13

9. Storage Cylinder Filling Procedure (Refrigerant Transfer) .........................................14

10. Connecting and testing the A/C system ....................................................................17

11. Recovery & Recycling Mode .....................................................................................18

12. Evacuation Mode ...................................................................................................... 21

13. Oil & UV dye Injection Mode ..................................................................................... 23

14. Refrigerant Charge Mode ...................................................................... 25

15. Auto Mode Function ............................................................................... 27

16. Cylinder Air Purge ..................................................................................................... 29

17. A/C Flushing Mode ................................................................................................... 30

18. Settings & Optional functions ……………………………………………………………. 33

18.1. Main Unit Set up ……………………………………………………………….. 34

18.2. How to set the workshop data on print report?........................................... 35

18.3. Wireless temperature sensor Set up ………………………………………… 36

18.4. Refrigerant Management, Operation History and Working Hours Reset…. 37

18.5. Refrigerant Recycling ................................................................................. 38