PELLET STOKER KMP PX22

6G>I:GBHL:9:C67 Installation Instructions - 2010.06.22 - 6/16

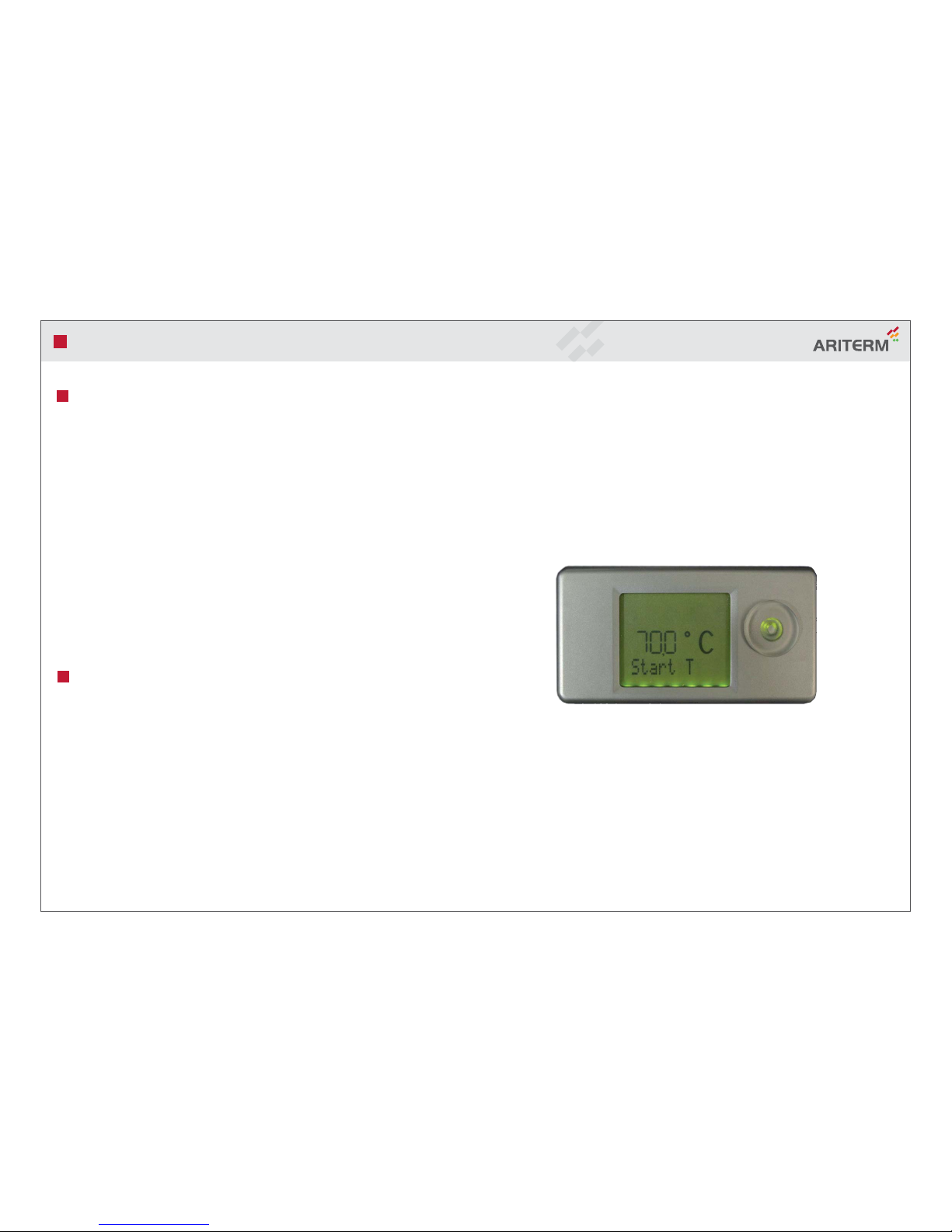

Start and setting

First start

The burner has default settings from the factory when delivered. It must be adjusted

upon first startup. Usually, the burner must be used with two output modes (high

and low), but the low output mode can be easily deselected or a third power stage

used (MIN).

If installed in a large or highly effective boiler giving low flue temperature (less than

180˚C), the stoker should be run in full power mode only. Thus condensation in the

chimney can be avoided. Note that a chimney equipped with an insert tube can

withstand a certain amount of condensation without risk. If in doubt, contact a

chimney sweeper.

Setting air and fuel levels

1. Fill the auger transporter with pellets before connecting it to the burner by

connecting the auger motor’s cable directly to the burner’s connection cable.

Allow it to run for a few minutes after is has been filled.

2. Set the starter dose (amount of pellets at ignition):

Adjust “Ign dose” in the Settings menu. Suitable dose is 3 - 4 dl.

3. Setting the fuel amount (output) for operation in high output mode: Start the

burner and wait 5 minutes after it has engaged high output mode (”Hi Power”

appears in the display). Adjust “Feed HI” in the Settings menu until combustion

is approved.

4. Setting the fuel amount (output) for operation in low output mode:

Deactivate high output mode by setting “HI 1/0?” to 000.

The burner automatically switches to low output mode “LO Power”.

Adjust “Feed LO” in the Settings menu until combustion is approved.

Do not forget to activate the desired output mode again.

5. If the output is to be adjusted, first change the combustion air “Air HI” and

“Air LO”, then the fuel amount by repeating steps 3 and 4.

Pellets quality

The burner can handle most types of clean wood pellets, however, 6 or 8 mm

pellets are recommended. The quality of the pellets must be Group 1 acc. to

Swedish standard SS187120.

Main menu

Start? (Stop?) - Confirm by pressing once to start (stop).

Start T - Press to select and adjust desired start temperature.

Stop T - Press to select and adjust desired stop temperature.

Usermenu - Press for Usermenu.

Back - Press for display.

Usermenu (Användarmeny)

Settings

SetCode (021)

Settings - Press for Settings.

Service - Menu for authorised service technicians.

View - Press for Display menu

(See levels, operating time, programme version etc.)

Clockset - Set date and time.

Back - Press for main menu.

Service - Menu for authorised service technicians.

Ign dose - Adjust the pellet amount at ignition.

TstlDose - Test the pellet amount at ignition.

FeedHI - Adjust the pellet amount at high output.

FeedLO - Adjust the pellet amount at low output.

FeedMIN - Adjust the pellet amount at minimum output.

Air HI - Adjust fan at high output.

Air LO - Adjust fan at low output.

Air MIN - Adjust fan at minimum output.

HI 1/0 ? - Activate high output.

LO 1/0 ? - Activate low output.

MIN 1/0 ? - Activate minimum output.

Default? - All the values are reset to factory settings here.

Language - Select language.

Back - Press for Usermenu.

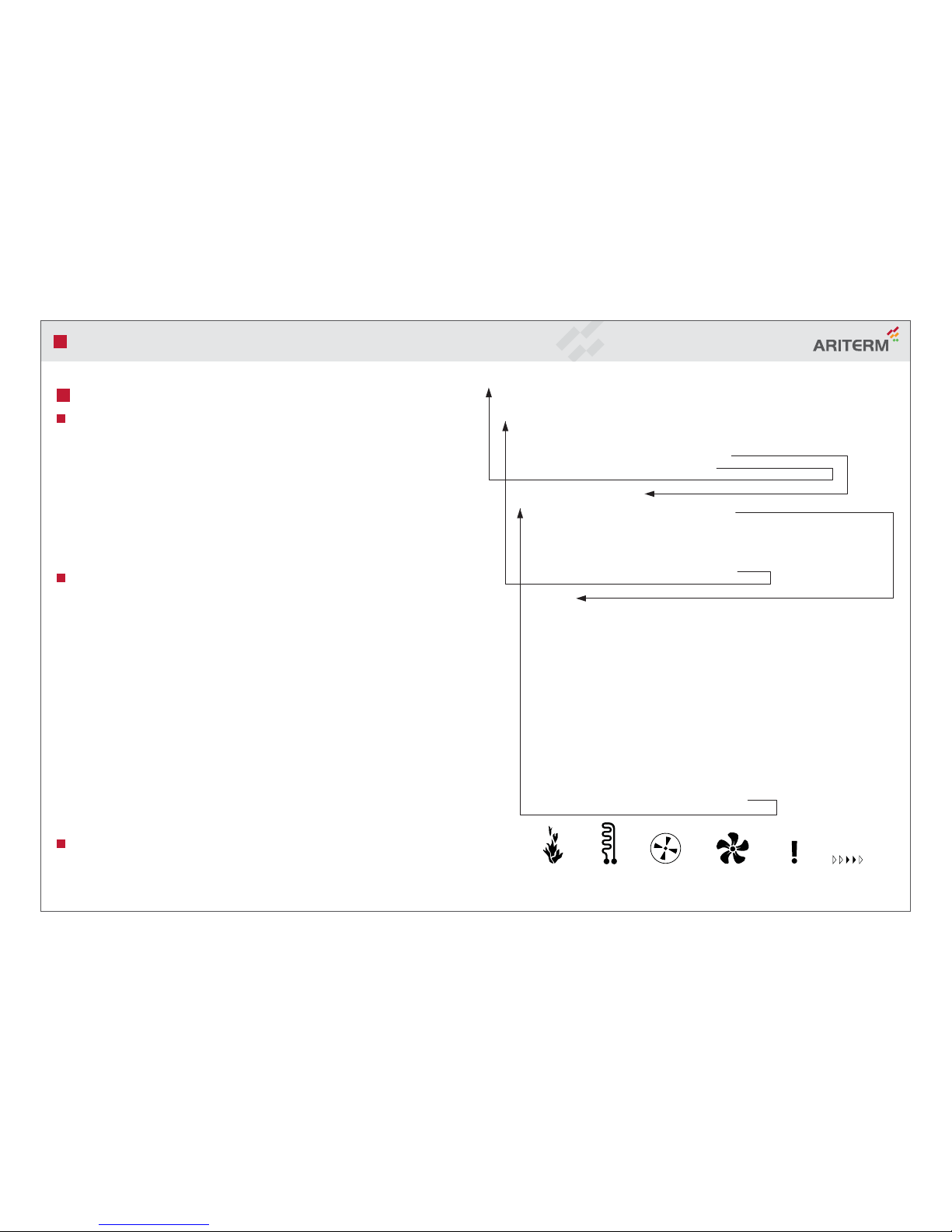

Flame

Indicated

Firing element

Activated

Feeder motor

Activated

Combustion fan

Activated

Fault function

Indicated

Burner in

operation