ARITERM SWEDEN AB Installation, Operation & Maintenance - 2007.08.14- 5/24

Biomatic+ 20/30 the new generation pellet boiler is equipped with a 20/30 kW

built-in pellet burner. A pellet burner has many similarities with an oil burner. e

difference is that heating with solid fuel produces ash that must be regularly removed

to prevent loss of efficiency or impairment of burner performance.

e boiler is designed to meet highest requirements as to operational reliability, conve-

nience, and safety.

Biomatic+ 20/30 belongs to the most efficient state-of-the art pellet boilers in today’s

marketplace. Optimal combustion efficiency and good insulation allows for a high

coefficient of performance while emissions to the environment are kept at a low level.

e boiler has automatic ignition but can always be ignited manually, if required. It

has two ignition programs depending on whether the burner is started from the OFF

position or from operating mode.

Operation of the boiler and its feed system are fully automated and are regulated in

three steps by the built-in control system. In the burn pot, pellets are mixed with air to

the ideal proportion to ensure complete combustion in a cost effective manner.

Biomatic+ 20/30 are equipped with an oversized

ash box to facilitate maintenance work.

Sweeping is mainly done from the soot-hatch on

top of the boiler but also through the rebox door

after the burner is pulled out.

Biomatic+ 20/30 consists of a combustion

chamber with flue pipes enclosed by a jacket

holding 140/142 litres of water. Heat generated by

the burner is transferred to the boiler water via

the combustion chamber and the flue pipes.

Heat for the radiator system is transferred via a

4-way shunt valve. In the shunt valve the boiler

water is mixed with return water from the radiators

so that a constant, correct temperature can be

maintained in the radiators in relation to the outdoor

temperature. is is a means to achieve better

heating economy.

e shunt valve can be regulated either manually or

automatically with a regulating device (optional).

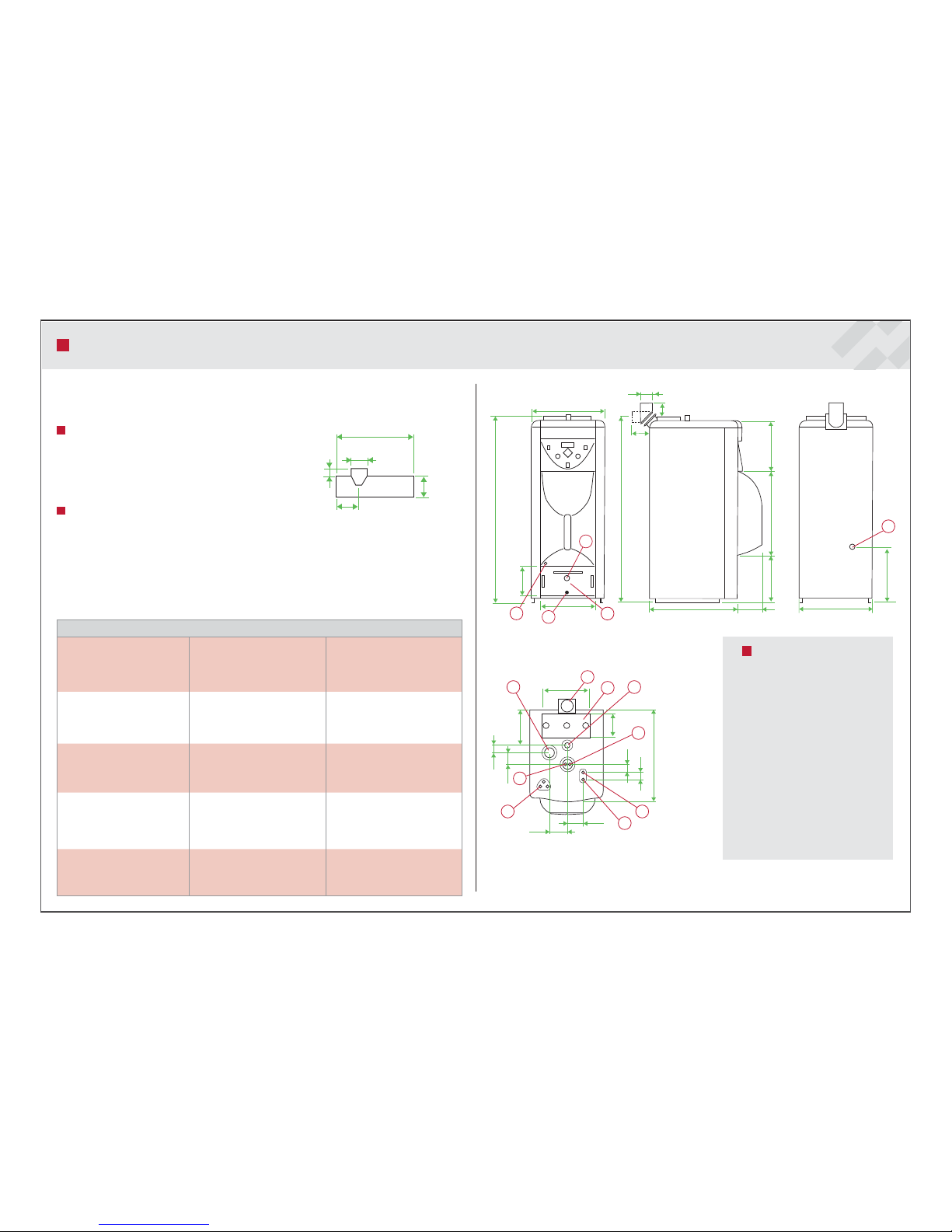

Small dimensions for easy installation

anks to its modest dimensions Biomatic+ 20/30 can be installed in boiler rooms

that would normally be considered too small.

Most of the piping connections are placed on top of the boiler. e terminal block

for electric installation is accessible from the control panel. Service work is facilitated

by the fact that all connections and components are easily accessible from the front.

Sweeping takes place through the rebox door or through a cleaning hatch on top of

the boiler. Ashes collect in the oversized ash box that is attached to the ash door. e

ash box holds 50 litre of ash and is emptied when necessary.

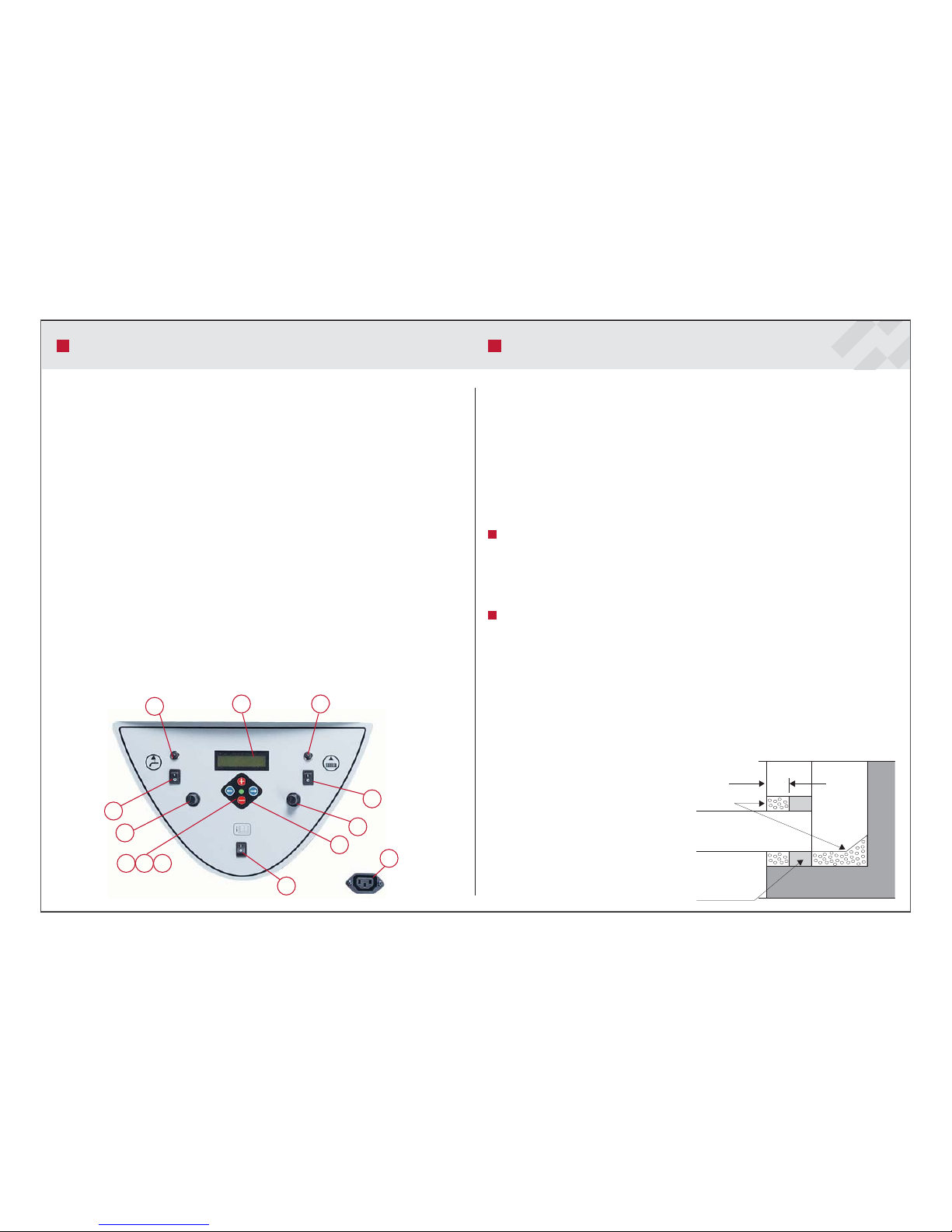

Hot tap water

e efficient plate heat exchanger will ensure that you always get“fresh” hot tap water.

A strainer has been installed in the cold water line to prevent the heat exchanger from

becoming clogged (the water quality should be checked).

e internal circulation pump is controlled by a flow switch, fitted on the hot water

outlet pipe. e whole heat-exchanger package is located behind the electric panel and

is easily accessible for service work.

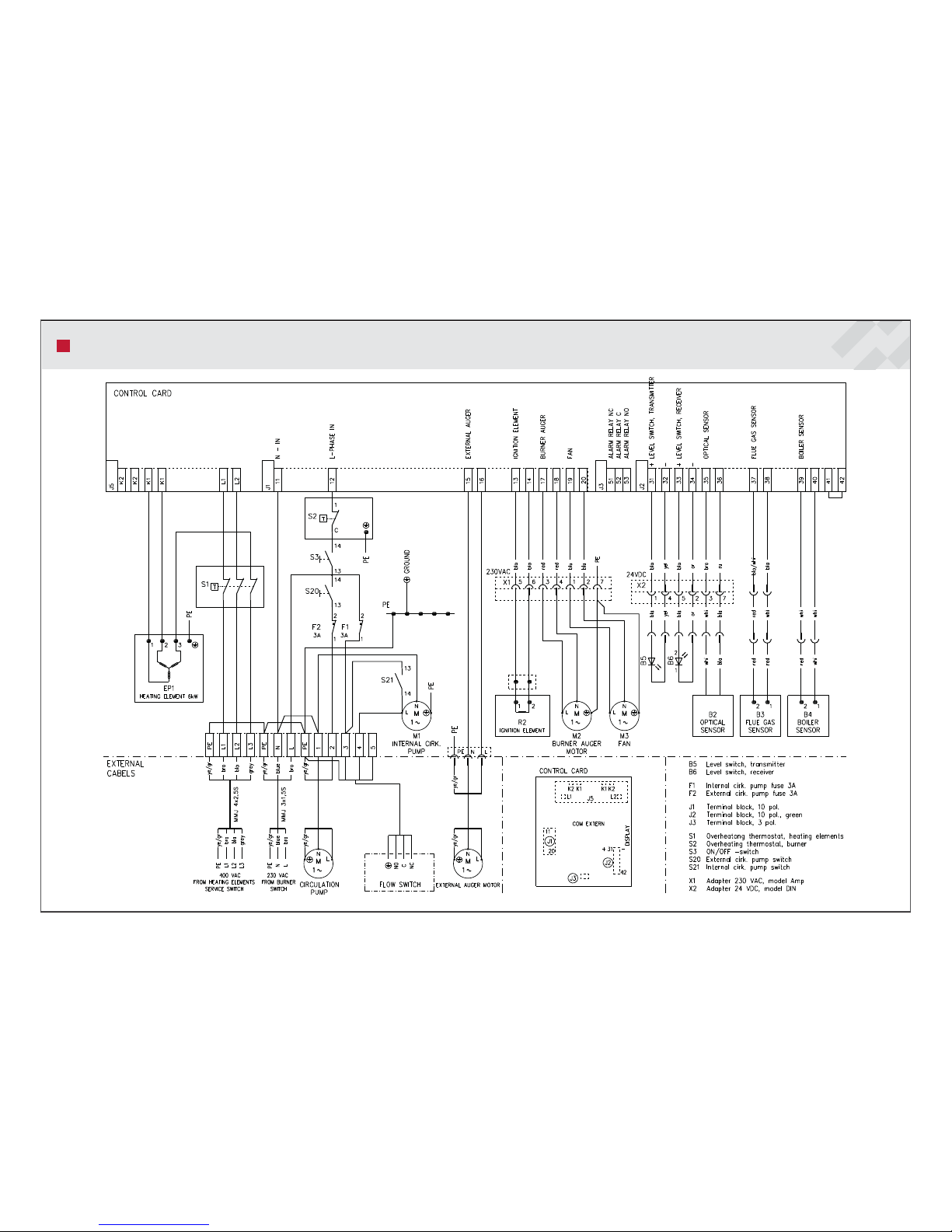

ATTENTION! Before servicing, disconnect the power to the boiler by switching

off the mains switches. Work on the boiler may only be carried out by a qualified

electrician.

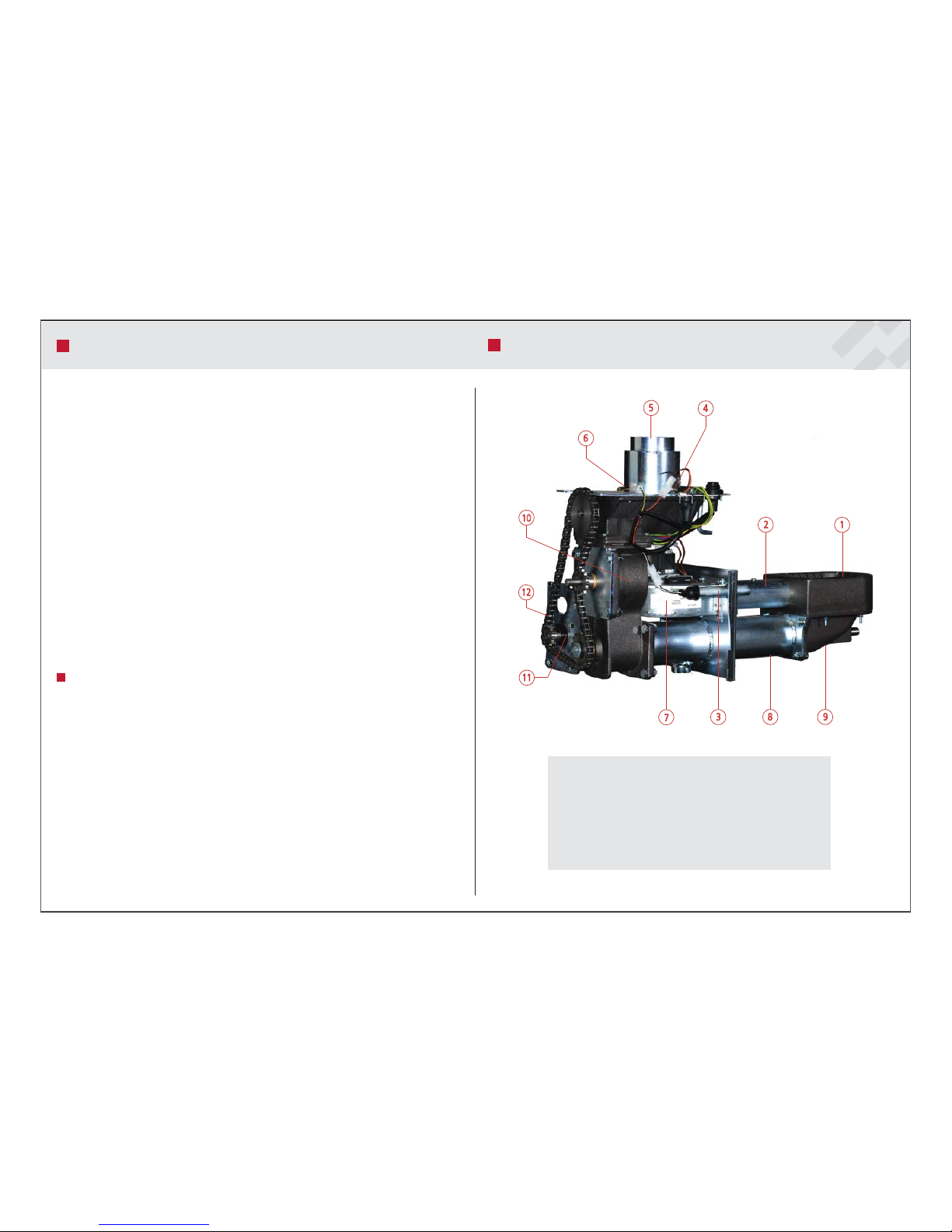

Front view of the heat exchanger

installation for hot tap water.

1. Plate heat exchanger

2. Internal circulation pump

OPERATING PRINCIPLE

1

Flow switch

cw hw

Strainer

2