It is important that the selected location for the equipment is suitable and

can adequately accommodate the unit physical size, the unit weight and

has safe and suitable access for correct operation and future maintenance

requirements.

Location of Equipment

Minimum Access Requirements

for Maintenance

• The unit must be mounted so that sufcient space is

allowed for installation and service access.

• Maintenance personnel need to gain access to all

parts of the unit and be able to remove components

such as fans and lters via access doors as required.

• Unless otherwise specied the following minimum

access should be available:

• 800mm clearance for electrical connections

• 1200mm for all access doors on the unit or if no

access door is provided 1200mm from the front of the

unit. Be very mindful that internal lters need to be

accessed regularly for cleaning.

• Every proposed installation must be subject to

an engineered design by a mechanical services

consultant. Armcor Air Solutions is not responsible

for installation of equipment in situations for which

the equipment was not designed or specied.

Noise Levels

• Do not locate equipment adjacent to sleeping

quarters unless background noise levels have been

checked and permitted by the appropriate authority.

• It is recommended that rubber supporting or

vibration absorbing pads be used to support the unit

to minimise any vibration being transmitted into the

building structure. We recommend wafe pad to be

used under the base frame and exible couplings be

tted to the supply and return ducts to reduce any

vibration transfer.

Fresh Air Inlet and Exhaust Air

Outlet

• The location of the fresh air inlets must adhere to the

Australian Standards 1668.2.

• The fresh air intake should be positioned clear of

any objects which could obstruct the airow and be

a minimum distance of 6 metres from any exhaust

discharge ducts from this unit or any other adjacent

equipment. Refer to Australian Standards AS 1668.2.

• The fresh air inlet and exhaust air outlet should

be tted with a cowl or other suitable means of

weatherproong.

• The exhaust discharge should be directed away from

any openable windows.

Drainage

Due to different moisture content levels of incoming

fresh air, heat exchange equipment can be subject

to some condensation. It is recommended that units

located in ceiling spaces or plant rooms are installed

with external drain trays under the complete unit.

Where an internal drain tray is tted, the condensate

drain outlet must be tted with a ‘P-Trap’ and have a

minimum ll of 20mm per metre length.

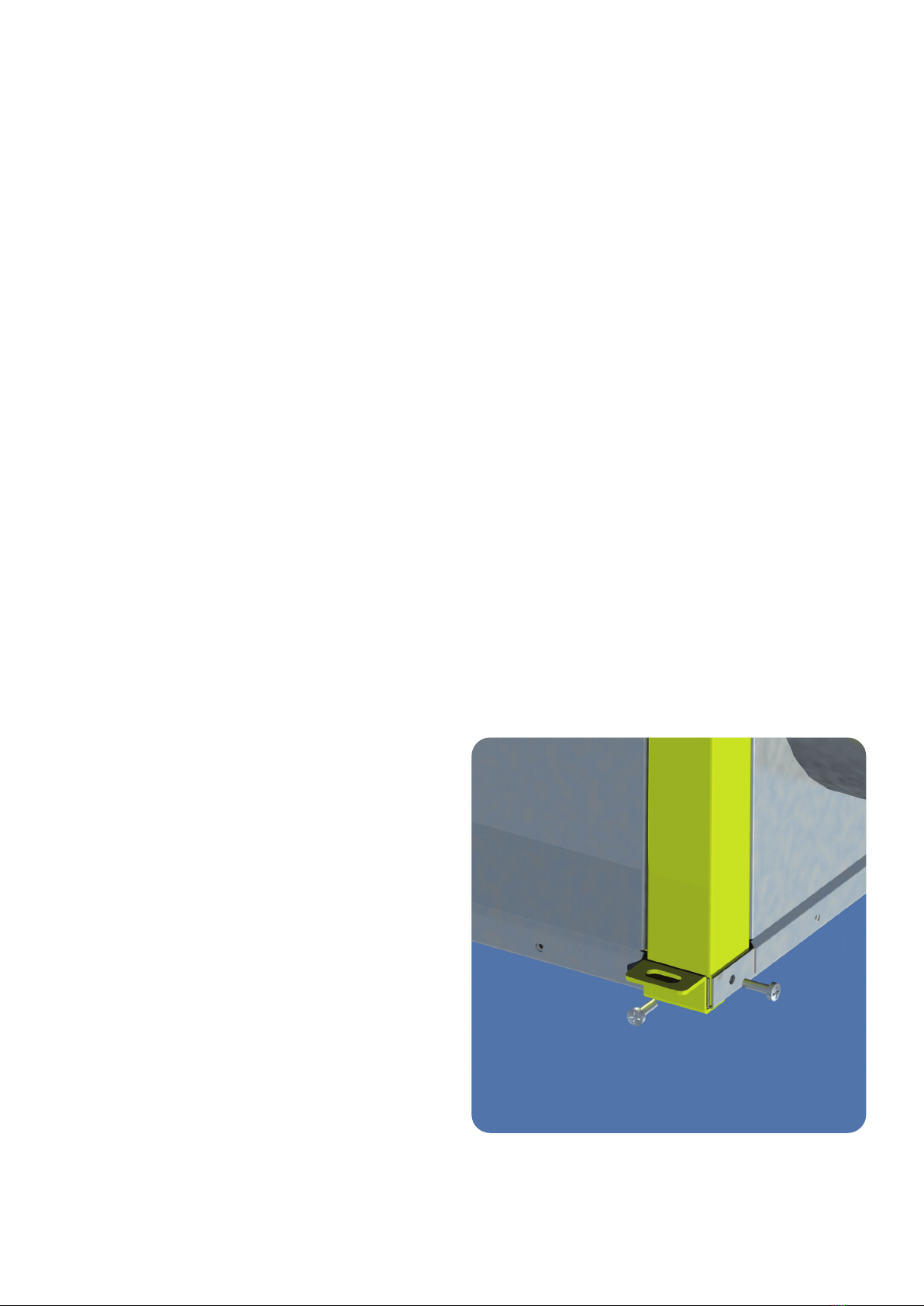

• Equipment should be installed with a positive fall

to ensure water drains away freely through drain

outlets. Drain lines must be as large as or larger than

the tting to which the line is being connected.

• All condensate drains must have a ‘P” Trap Fitted and

have a minimum fall of 20mm per metre length.

• If drain lines are to be extended from the inside to

the outside of the building, they must be extended

beyond walls of the building to eliminate the

possibility of damage caused by drain water running

down the exterior surface of the building wall.

• When a drain is exposed to freezing temperatures or

subject to the formation of condensation, the drain

should be insulated.

IMPORTANT: ALL UNITS LOCATED INDOORS MUST HAVE

DRAIN TRAYS UNDER THE COMPLETE UNIT.

Armcor_XCM–Compact Multiow ERV Installation and Operation Manual 2021 5