2

Troubleshooting Guide

1. Closethe gatevalvesbefore andafterthe pressure

reducingvalve. Open theglobevalve slowlyin the

bypass line and blow down the inlet piping. Adjust the

openingof thebypassvalve sothe safetyvalve does

not blow. After blowing the system down, close the

bypassvalve.

2. Slowly open the inlet side gate valve to the fully open

position,and partially openthe outlet valveso only a

small amount of steam or air can pass.

Start-Up and Adjustment Procedures

Improperadjustment ofthe pressurereducing valvemay causehunting, scaleproblems, waterhammer, etc.,and

damageto thevalve itself. Damagedpressure gauges,leakage oropening ofa bypassvalve, orclogging of aninlet

strainermay causeproblems similarto thatof amalfunctioning reducingvalve.

Adjustthe valveas follows:

3. Toincrease thedownstream pressure,place yourhand

onthe top ofthe adjusting handleand pullvertically

up. When in the fully up position turn the handle

clockwise until the desired pressure is obtained on the

downstreampressuregauge.

4. Release the handle and it will automatically retract

which will lock the adjusting handle in place.

5. Slowlyopen theoutlet valveto the fullyopen position.

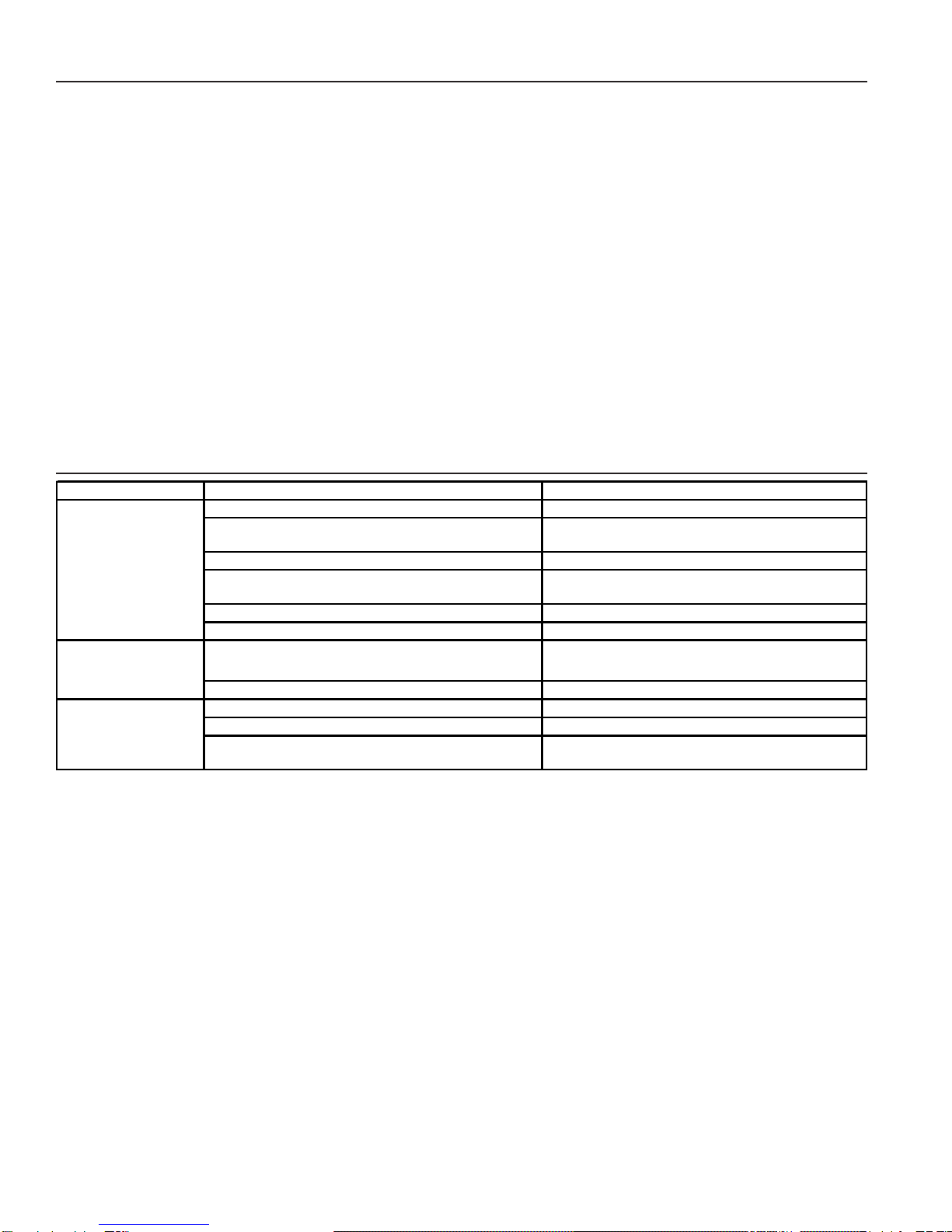

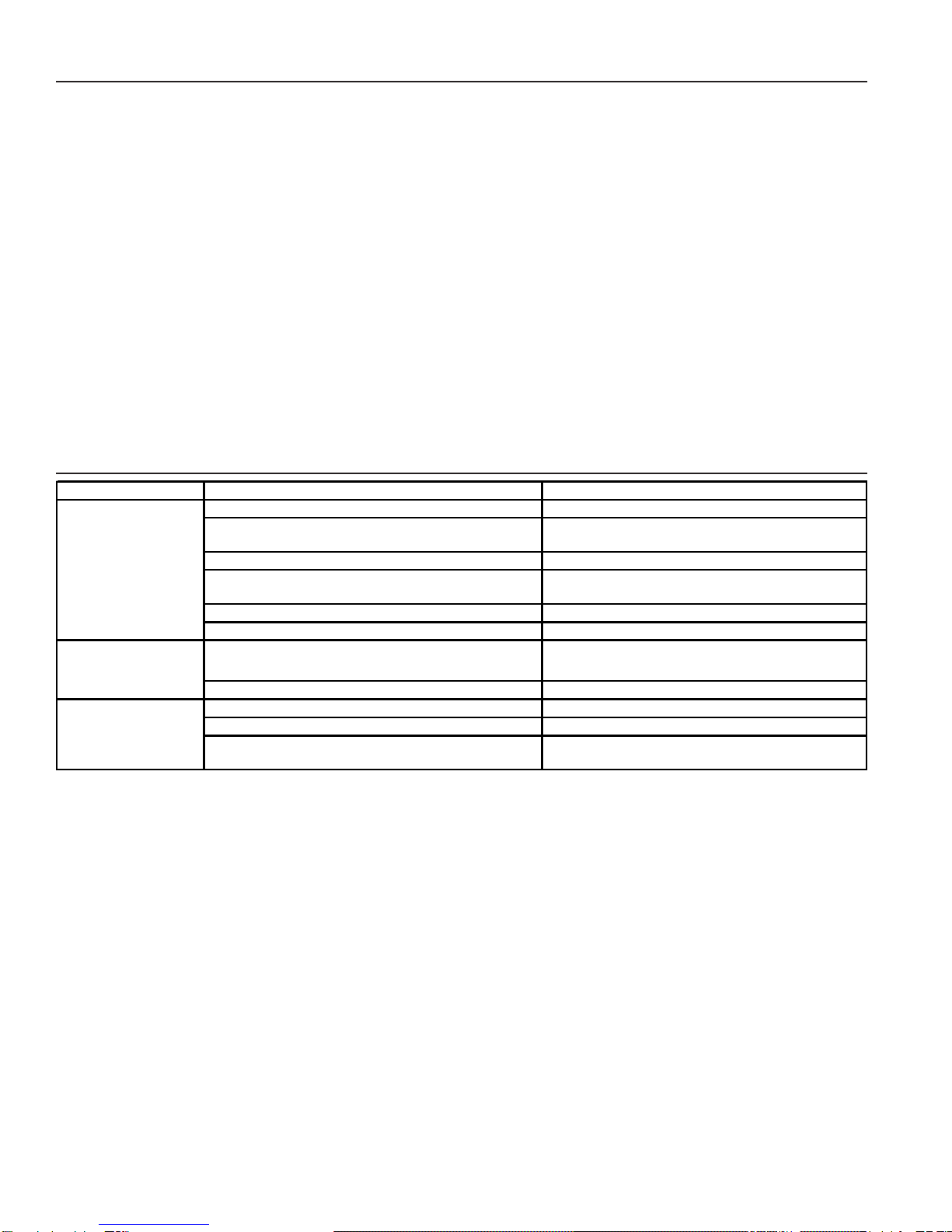

Problem Causes Solutions

The inlet pressure is too low or high. Change the pressure to the appropriate level.

The sensing port of the outlet pressure is clogged with

foreign matter. Disassemble and clean the sensing port.

The valve size is smaller than what is required. Change the valve size to the appropriate one.

The adjustment is not appropriate. Readjust according to the adjustment procedure.

(See start-up procedure)

The inlet strainer is clogged by foreign substance. Disassemble and clean the strainer.

The pressure gauge is not functioning properly. Replace the pressure gauge.

The valve or valve seat is contaminated by foreign

substance. Disassemble and clean the valve or the seat.

The by-pass valve is leaking. Repair or replace the by-pass valve.

The reducing ratio is excessively large. Reduce pressure by staging with second PRV.

Water hammer (for steam service). Install a steam trap at the reducing valve inlet.

There is a fast closing valve near the PRV. Provide as long a distance as possible between

the two valves.

The desired pressure

cannot be obtained.

The outlet pressure

rises higher than the

specified pressure

Abnormal noise is

heard.