Page 4 Jandy® Pro Series, Slide Valve & Backwash Valve | Installation & Operation Manual

This document provides instructions for installing the

Jandy Pro Series Pro Series Slide Valve. The instructions

must be followed exactly. Read through the instructions

completely before starting the procedure. Please save these

instructions.

The Jandy Pro Series Pro Series Slide Valve is designed to

be used on either sand or diatomaceous earth (DE) lters

with a center-to- center dimension of 8 inches (center of

the inlet port to the center of the outlet port). Combined

with the Jandy Pro Series Pro Series Versa-Coupler, the

Slide Valve can be used on lters with center-to-center

dimensions of 7 to 9 inches.

For Jandy Pro Series Filters, Slide Valve p/n SVLV8 (with

unions) is ready to mount to DEL48 or DEL60 model

lters (in which the top port is the lter outlet), BWVL-

SLD mounts to DEV48, DEV60 or JS series model lters.

If mounting a Jandy Pro Series Slide Valve on Pentair® or

Sta-Rite®* Filters, use a combination of p/n SVLV2 (Slide

Valve without unions) and p/n 8044 (Versa-Coupler Kit).

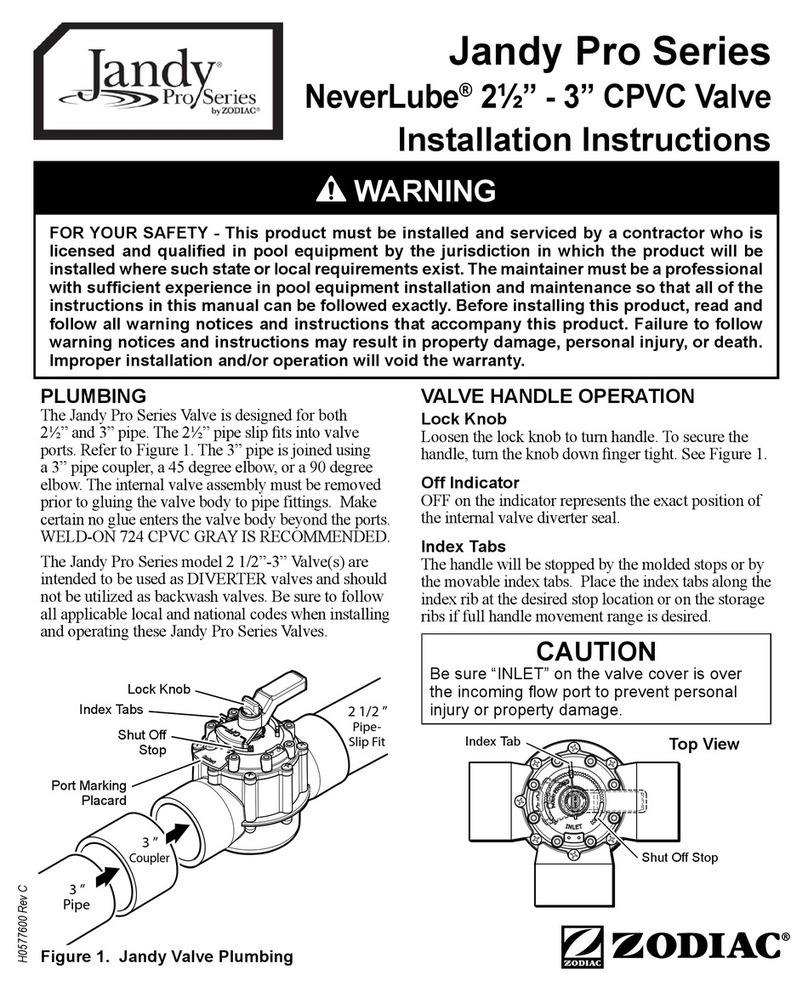

The Slide Valve is a two position valve. The valve handle

must be fully extended or fully depressed. This valve can

not be throttled. To operate the Slide Valve on a DEL,

DEV or JS series lters in normal ltration mode, fully

depress the handle. To operate the Slide Valve from a

manufacturer other than Jandy Pro Series (with the inlet

being the top port) on a sand lter in normal ltration

mode, fully extend the valve handle. See Figure 1.

1. Remove the Slide Valve from the packaging.

Twist the handle on the Slide Valve several times

to verify that the piston moves freely.

Ensure that all electrical power to the system is turned

off before approaching, inspecting or troubleshooting

any leaking valves that may have caused other

electrical devices in the surrounding area to get wet.

2. Turn off all power to the system. For retrot

installations only, follow steps "a" through "d".

For new installations skip steps "a" through "d"

and proceed to step 3.

a. Open the pressure relief valve on top of the lter.

Wait for all air to evacuate the system.

b. If the lter is below pool level, close the suction

and return line valves to isolate the ltration

system.

c. Remove the drain plug from the lter. Let the

water drain from the lter.

d. Remove the existing valve from the lter.

3. Remove the two (2) o-rings from the packaging.

4. Place the o-rings on the face of the union tail

pieces, where the face of the Slide Valve union

will connect to the lter bulkheads, see Figure 2.

Make sure each o-ring is properly seated into the

groove of each union tail piece.

The Slide Valve has molded labels on each port. (See

Figure 1.) The ports on the SVLV8 are equipped with

union connections that match the connections on the

filter ports. Do not use pipe sealants on union nuts.

5. Hold the Slide Valve upright and place onto the

lter bulkheads. See Figure 3.

6. Tighten both union nuts to secure the valve on the

lter.