Fixed speed settings

1-4 speeds1. For

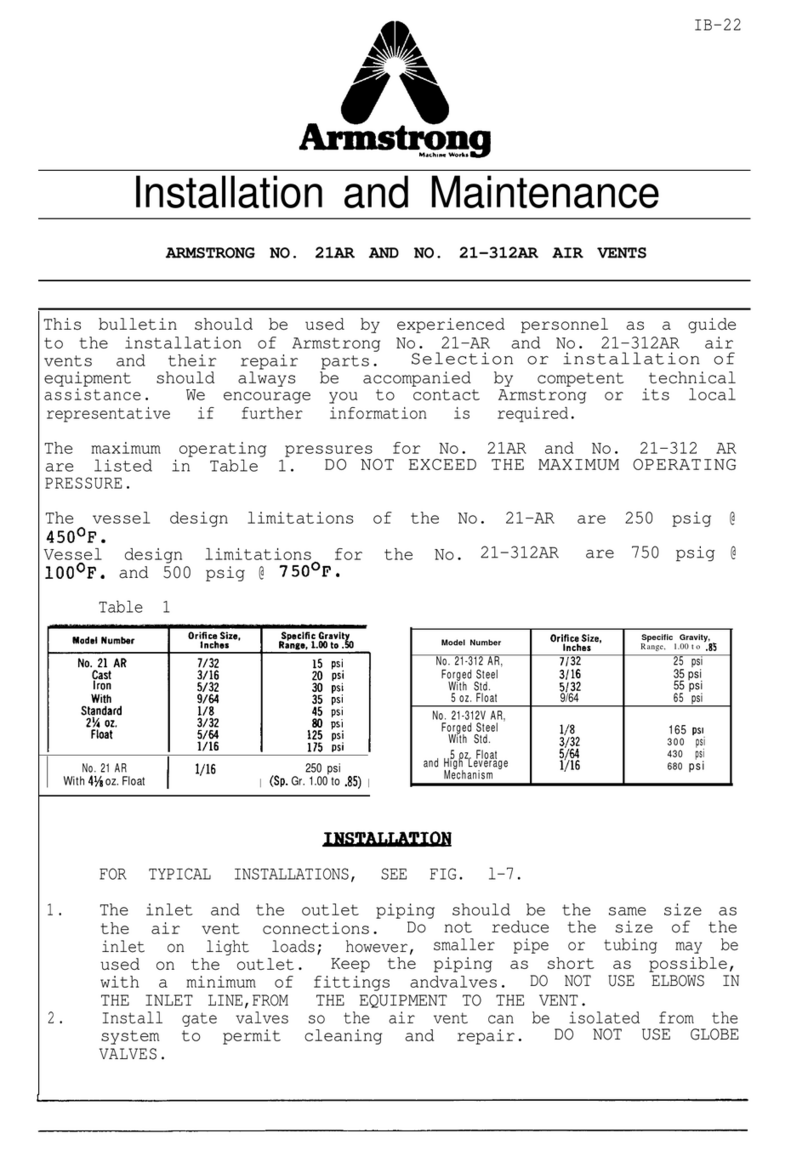

small systems and 4.

for large systems or

venting

Fixed speed for

systems with constant

resistance and radi-

ant floor heating

systems.

GENERAL

In all AGE circulators, Pressure Loss Compensation (P.L.C.) is included in

the control, which means that the circulator does not follow a constant differ-

ential pressure but takes into account the decreasing pressure needs at

decreasing flow. This setting isin the auto controlling mode. See fig. 4.

Signal LED

No light Main supply switched off

Green light Normal operation – power on

Red light Error detected by the electronics

Description

ERROR SIGNALS

The red light on the back of the terminal box will, in case of an error, indicate

the type of error detected by the electronic. Approximately every minute the

light will blink a number of times, except 31-07, which is permanently illumi-

nated in the event of a fault.

Number of blinks

1 Under voltage from the power supply

2 Over voltage from the power supply

3 Instantaneous over current

Error

4 Internal power failure

5 Continues power overload

6 Overheating of the electronic

7 Memory failure

8 Motor overheated

9 Program failure

ERROR RELAY

With the exception of the 32-07, the AGE

has a fault relay. The relay has both a NC

and a NO connecting. See fig. 3.

Fault Cause Action

The circulator is not

running. See under heading

”Signals” Reset fault indication.

Check main supply and fuses.

Circulator will not start /

is running irregularly. Impurities in the

circulator. See under heading

“Service/ Maintenance”.

The circulatoris running

but no flow. Air in the system.

Closed valve Vent circulator and

system.Open valve.

Circulator noisy. Circulator speed too

high. Static head too

low. Air in system

Decrease set point of

control. Increase inlet

pressure. Vent circulator

and system.

SERVICE / MAINTENANCE

Armstrong’s AGE Series range of glandless circulators is virtually

maintenance free and in a well designed system should give many years of

trouble free operation.

If motor shaft is seized as a result of a long period without use or due to

accumulation of impurities, it should be freed. Insert a screwdriver through

the venting plughole and into the slot in the end of the shaft and rotate.

Please note: Any repairs required to the internal electrical parts of the circu-

lator, are to be carried out by an Armstrong approved service organisation.

Transport, Handling and Storage Instructions

a. Transport.

i . AGE circulators are despatched fully assembled. AGE

circulators are packed for transport by mornal road, sea and air

carriers.

b. Handling

i. Crushing Hazard.

Ii. When lifting an AGE circulator above a weight of 25 kg,

use lifting equipment haveing a safe working load rating

suitable for the load specified. Use suitable slings for lifting any

circulator..

c. Storage

i. Short term Storage (six weeks). If the AGE circulator is not to be

installed immediately after unpacking, then it is to be be stored in

a cool dry dust free location.

Ii. Long term storage. If the AGE circulator is not to be installed for

period of longer than six weeks after receipt on site, then it is to

be retained in its packing case. If the casing case is disposed of,

then the inlet and outlet connections are to be blanked off with

suitable clean covers to prevent ingress of damaging solids.

DECLARATION OF CONFORMITY

Armstrong hereby declares that this unit complies with the following

relevant provisions

i. EC Machinery Directives 89/392/EEC, 91/368/EEC, 93/44/EEC,

93/68/EEC

Ii. Electromagnatic compatability standard 89/336/EEC, 02/31/EEC,

93/68/EEC

iii. Applied harmonisation of standards EN809, EN50 081-1,

EN50 082-1, EN50-081-2, EN50-082-2.

Fig.3

SIGNALS

AGE circulators have two LED’s on the terminal box for status indication.

Power to the circulator is indicated with the green LED. The red LED will

be on if the circulator detect a fault. Reset is carried out by switching the

mains supply off for 5 sec. and then on again. See fig.5.

1

1

2

2

3

3

4

4

Auto max.

Auto min.

Fig.4 Fig.5

FAULT FINDING

Red = Alam

Green = Power on

For Armstrong locations worldwide, please visit www.armstrongintegrated.com

S. A. Armstrong Limited

23 Bertrand Avenue

Toronto, Ontario

Canada, M1L 2P3

T: (416) 755-2291

F(Main): (416) 759-9101

Armstrong Holden Brooke Pullen

Wenlock Way

Manchester

United Kingdom, M12 5JL

T: +44 (0) 1612 232223

F: +44 (0) 1612 209660

Armstrong Design Private Ltd.

(Unit 1- Armstrong Manufacturing Center)

490-L, 4th Phase, Peenya Industrial Area,

Bangalore, India 650 058

T: +91 (80) 4149 2832

F: +91 (80) 4117 9783 © S.A. Armstrong Limited 2010