b

&

8

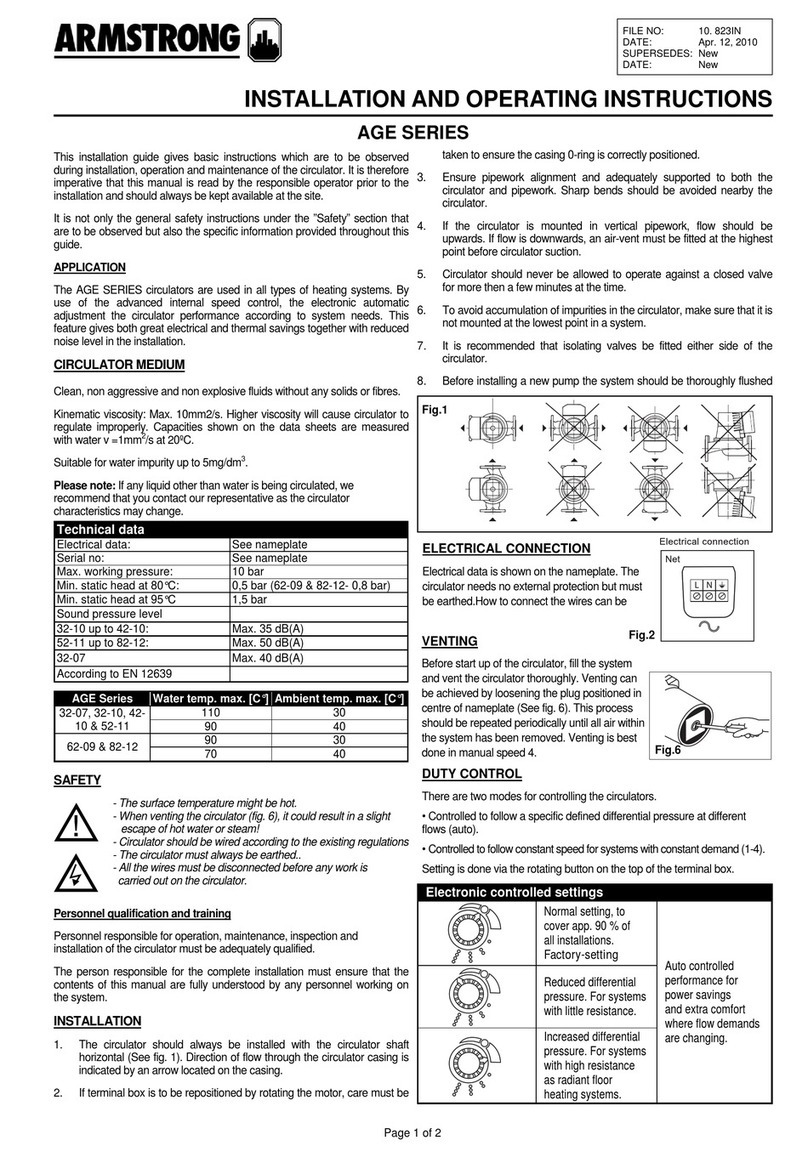

ARMSTRONG 21AR AND 21-312AR AIR VENTS

3.

4.

5.

6.

7.

8.

9.

10.

11.

1.

2.

Before installing the vent, flush out the line to remove

loose dirt.

Use pipe dope or teflon sparingly and on male

threads only. Leave the end thread exposed to avoid

introducing sealant into the system.

DO NOT use a pipe strainer in the line leading to the vent.

For occasional venting, a single pipe

3/4"

or larger is a

suitable connection.

Once the system is filled with water,

only small additional amounts of air need to be vented, so

there is no difficulty in getting air to enter the vent

countercurrent to the water displaced.

For continuous operation,

an equalizing line is usually

necessary. Where gas enters the system continuously or when

very fast venting is required,

an equalizing line should be

provided, as shown in Fig. 3.

Be certain the vent is installed properly, with the CAP AT

THE TOP for air and gas relief service.

Install the air vent at the high points of the system.

See

the accompanying diagrams for typical installations.

Air vents should be installed so that they can be checked

periodically.

A drain line should be piped to a floor

drain,

slop sink, or other visible location where

maintenance personnel can regularly check for leakage.

The pipe plug in the cap of the air vent can be replaced

with a test cock or test valve for vent testing or even

manual venting. A test cock makes it possible to check that

the vent is not air bound due to the orifice being clogged.

In addition, the manual test cock will enable the operator

to vent the unit manually should the automatic vent fail.

If the vent is installed in an inaccessible location, a

l/4"

copper tube drain line to a slop sink, floor drain, or other

visible location makes periodic inspection practicable.

No discharge from the vent is normal on hydronic systems,

but is not proof that the vent functions properly. To check

the air vent,

crack the test cock. If the vent is working

correctly, a little air should escape, followed by water.

Vent Does Not Open.

If a lot of air escapes out of the test cock before water

begins to discharge, it is a sign that the vent body was

full of air and that the float did not sink to open the

valve,

or that the valve was plugged. Isolate the vent by

closing the gate valve before opening for inspection.

a.

Remove the vent cover and inspect the mechanism. If

the mechanism cannot be made to operate freely after

cleaning and inspection, order a new assembly.

b.

Check the orifice for dirt. Clean the orifice. If the

orifice cannot be cleared, order a new mechanism.

c.

On new installations, an air vent may fail to open if

the orifice is too large for the operating pressure.

Replace the mechanism with one sized for

your

operating

pressure.

2