Armstrong InternationalArmstrong International

Parc Industriel des Hauts-Sarts, 2ème avenue 4, 4040 HERSTAL - BELGIUM

Phone: +32(0)4 240 90 90 Fax: +32 (0)4 240 40 33 armstrongarmstronginternational.com

Armstrong

Contents

Revision History . . . . . . . . . . . . . ..1

Safety . . . . . . . . . . . . . . . . . . ..2

Abbreviations and Acronyms. . . . . . . . . .3

General Description . . . . . . . . . . . ..4

Calorimeter Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ....5

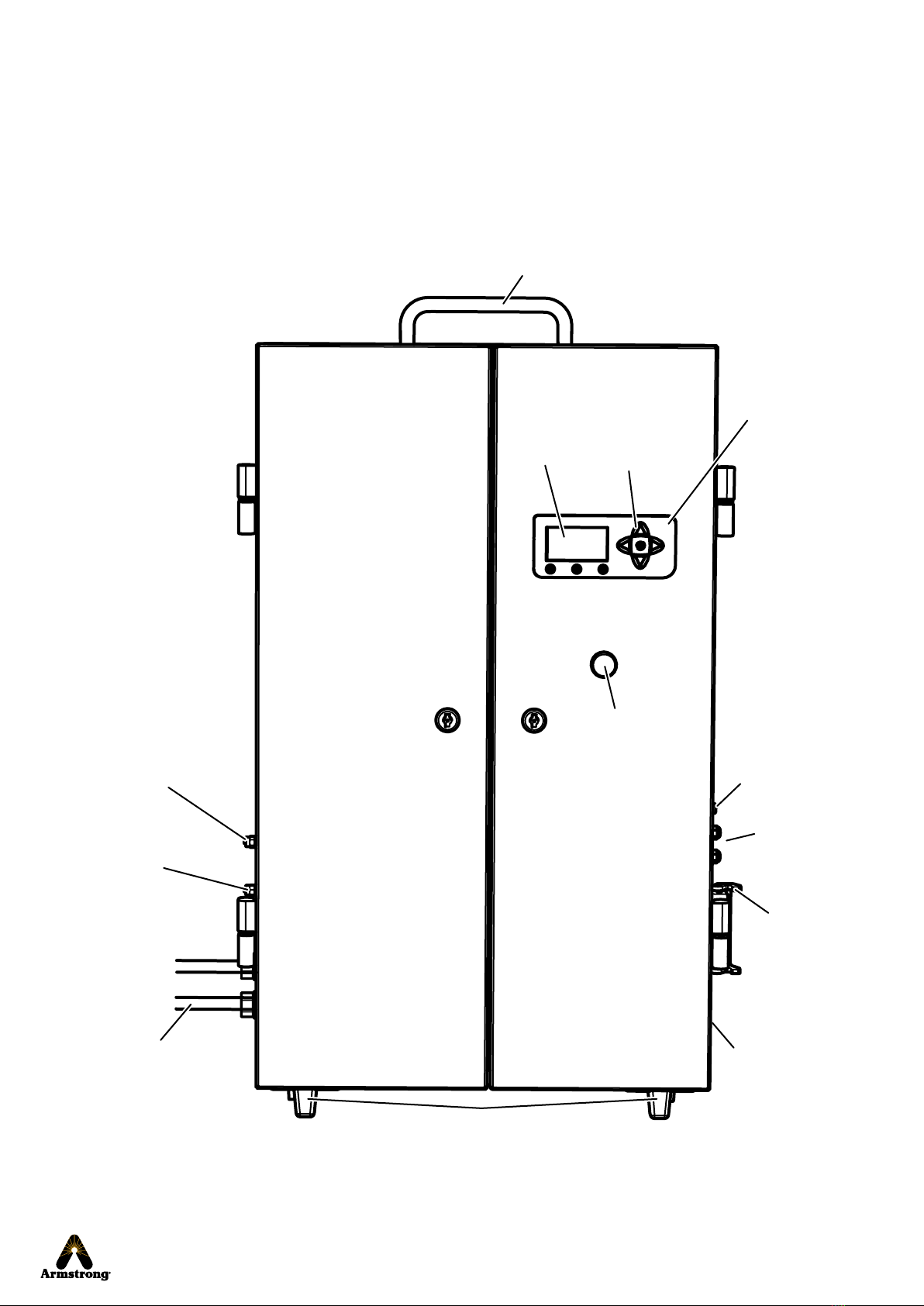

Cabinet Exterior . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ....6

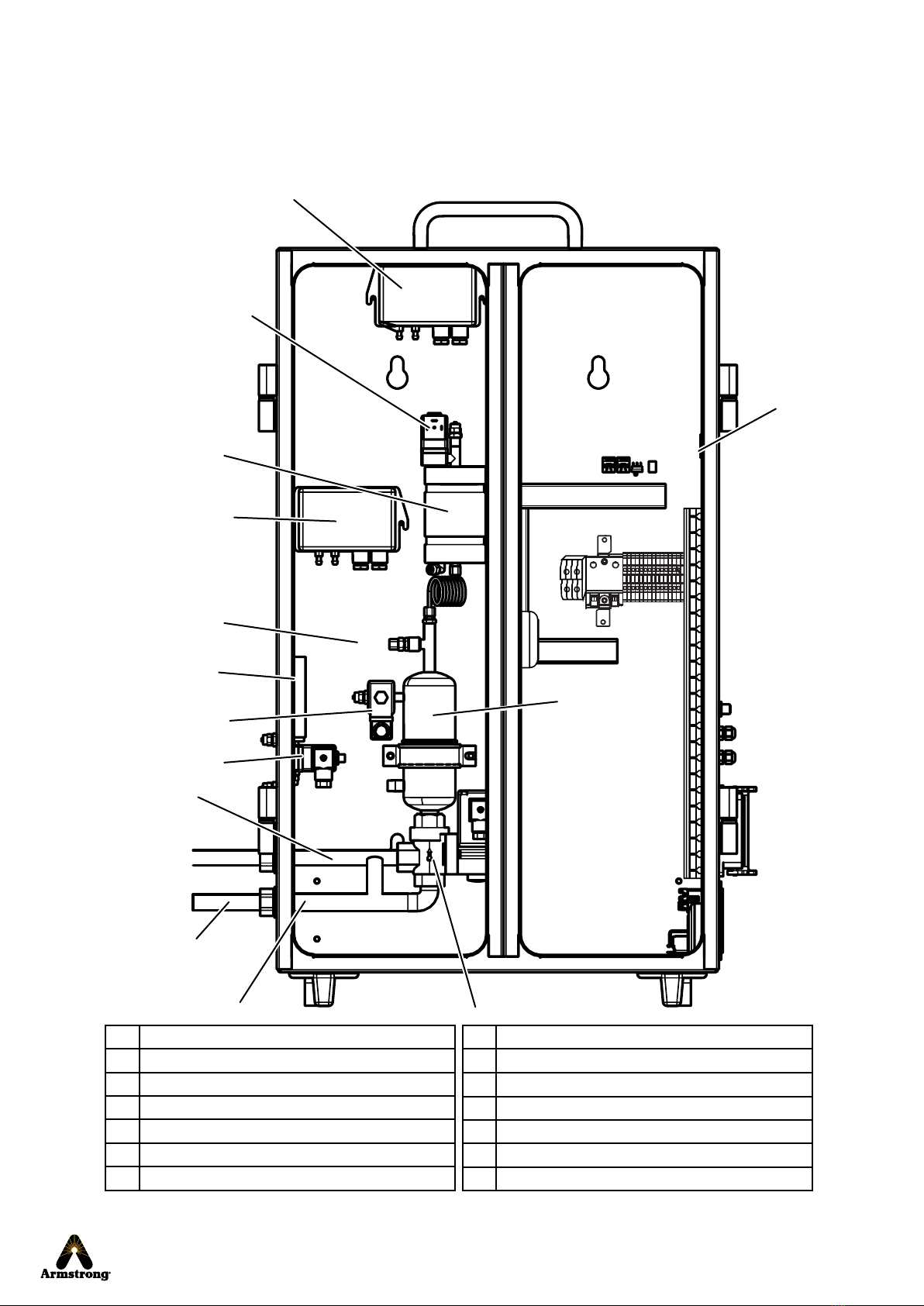

Cabinet Interior . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ....7

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ....8

Installation . . . . . . . . . . . . . . . . . .9

General Considerations (Site Selection). . . . . . . . . . ....9

Typical Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Start-Up Procedure . . . . . . . . . . . . .14

Software Navigation. . . . . . . . . . . . . 15

Standard Screens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Special Screens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Troubleshooting . . . . . . . . . . . . . . . 19

Software update. . . . . . . . . . . . . . . 24

Component and Parts List . . . . . . . . . . 25

Product Certifications . . . . . . . . . . . . 26

Appendix One: Wiring Diagram . . . . . . .27

Appendix Two: Principle Schematic . . . . .28

Appendix Three . . . . . . . . . . . . . . . 29

MODBUS Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Limited Warranty and Remedy. . . . . . . . 30