Armstrong InternationalArmstrong International

247-EN V1.17

Steam QM-1

Page 1 of 25

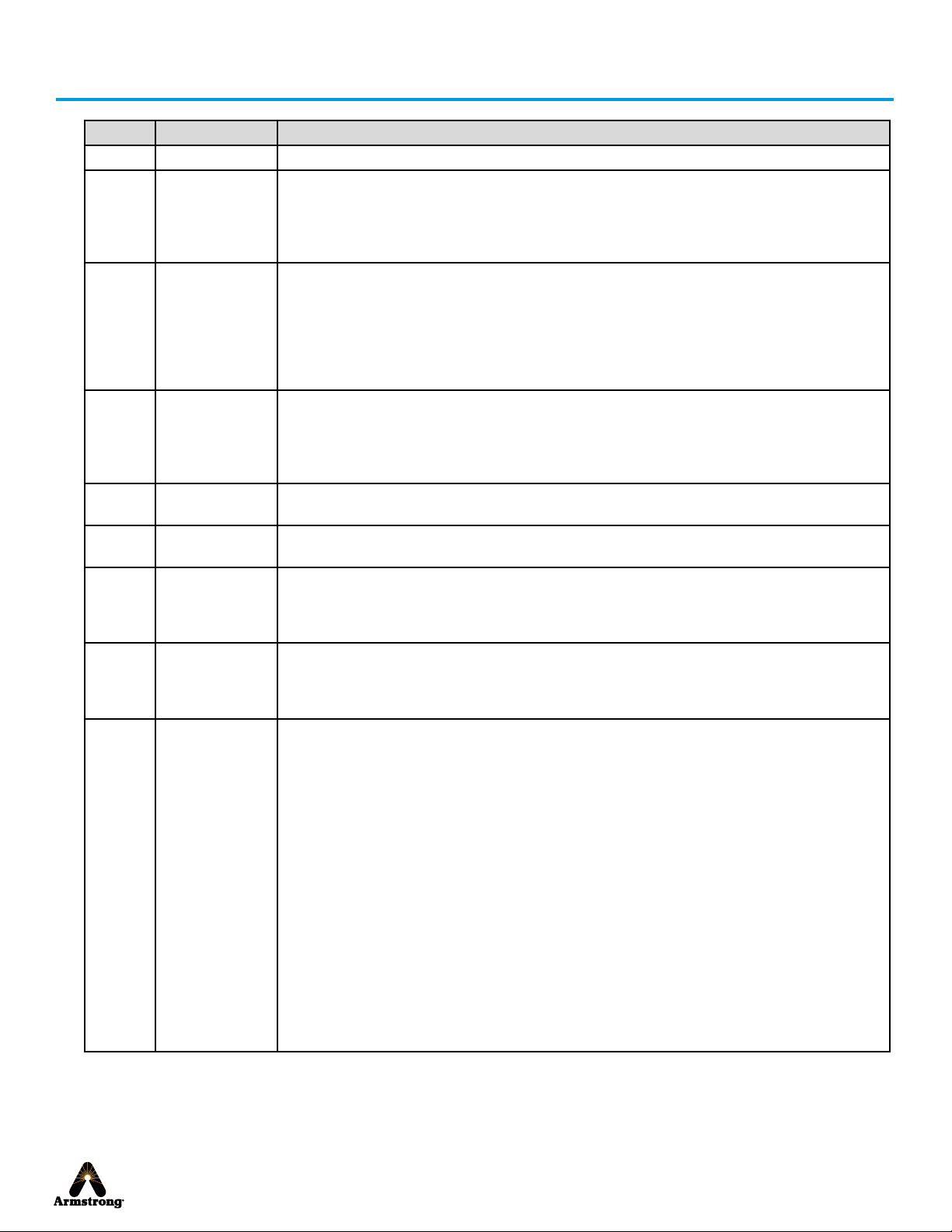

Revision History

Version Release Date Description of Changes

1.0 May 12, 2014 Initial

1.1 June 3, 2014 Page 4, chart with tiltle: Specication, 5th line with electrical information: "12 VAC or 15 -

24 VDC 5 W" replaced by " 12VAC 50/60Hz or 15-24 VDC / 30W"

Page 4, bottom of the page. The remark : "The product must be powered by an isolated

external power supply in low voltage." has been added.

Page 21, Appendix one: wiring diagram. "F1 : 1A" replaced by "F1 : 1AT 250V"

1.2 October 22,

2014

Page 1, updated drawing

Page 4, updated specications table

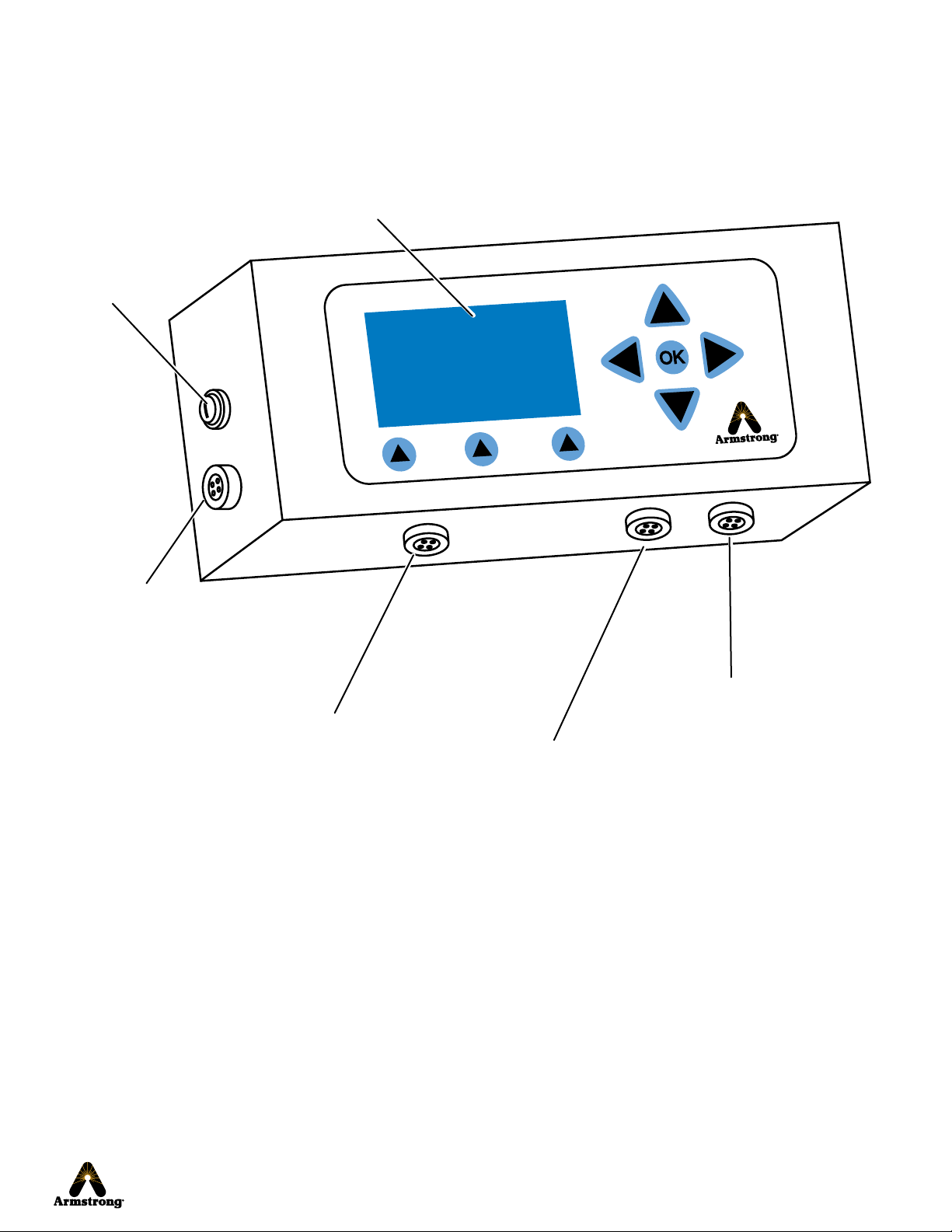

Page 7, updated cabinet drawings

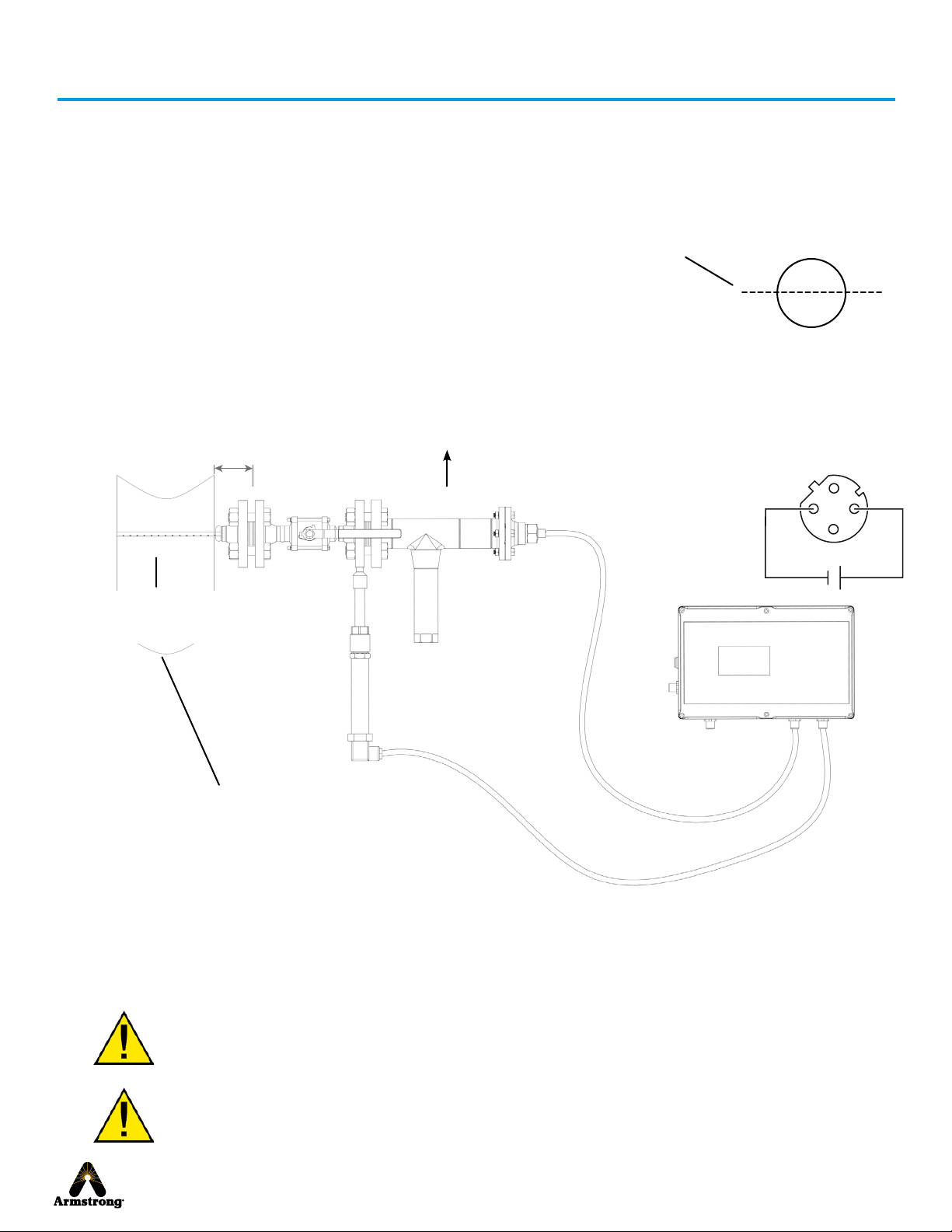

Page 9, added drawing to start-up procedure

Page 18, added recalibration procedure

Page 19, revised the 5 volt drawing

Page 23, Modbus slave and master connection

1.3 March 25, 2015 Page 13, added serial mode information on screen section

Page 21, updated standard comformity list with UL 61010-1

Page 23, added address and updated mode on chart Parameters / Value

added slave information on charts (Function 0x02 and Funcitons 0x04)

Contents, updated pages nr.

1.4 August 25,

2016

Page 8, modication of the ambient temperature.

IOM reference update: 1249 turn to 247.

1.5 April 5, 2017 Page 4, updated specications

Page 24, updated max pressure

1.6 January 22,

2018

Page 20, item nr. updated: D60740 to D94998

Page 23, update to the chart Function 0x04 Read Inputs Registers remove (barre) as it is a

misprint

Page 24, Appendix 3, minimum value of the dryness fraction graphic update

1.7 August 9, 2018 Page 5: graph has been updated. Flange information is now: EN 1092-1 DN15 PN100

Page 20: components list updated. Part Nr. updated: D60722 to D60738

spare part and components lists updated: for D94998 and D60738 PN40RF becomes

PN100RF

1.11 April 29, 2020 Cover, updated image

All pages - Version update from 1.6 to 1.8, psi and bar to psig and barg

Page 4, updated specications and warning statement, 12VAC changed to 15VAC

Page 5, updated image and some callouts

Page 6 & 7, updated image

Page 8, updated image and added callouts, changed hose to pipe in warning statement

Page 9, added callout and extended Note copy

Page 10 updated image, changed hose to pipe in copy, additional statement added to

waring symbol.

Page 13, changed specic minutes to x-xx

Page 15, changed exible hose to discharge pipe

Page 17, updated Pressure transmitter and Materials needed statements. Added 'or dry

well' to Caibration Procedure

Page 18, updated statement 2 and removed 'caution' statement

Page 19, updated image, added callouts 7 and 8 to image and table

Page 22, added copy for supply drawing

Page 23, replaced entire Modbus Connection page

Page 24, added startement regarding graph values