Arometrix FRACTION FINDER User manual

Arometrix FRACTION FINDER

USER MANUAL

YOU MUST READ THIS MANUAL BEFORE USE

WARNING: NEVER LOOK DIRECTLY INTO THE LIGHT SOURCE

2

TABLE OF CONTENTS

Section 1: Overview 3

Section 2: Fundamentals 3

Section 3: Unpacking and Inspecting 3

Section 4: Installation 4

Section 5: Understanding the Interface 5

Section 6: General Procedure for Short-Path Distillation 8

Section 7: Issues 12

Section 8: Software Update Instructions 14

Section 9: Optical Measurement 14

Section 10: Appendix 14

Section 11: Terms and Conditions 15

Arometrix, Inc. Sales@arometrix.com arometrix.com/resources

3

Section 1: Overview

The FRACTION FINDER is Arometrix’s real-time molecular monitoring system for botanical processing. The

technology utilizes fluorescence spectroscopy to detect and measure molecules in real-time. Knowing the

flow and the relative concentration of botanical molecules, and whether that intensity is increasing, or

decreasing can help operators make optimal process decisions. In our work, we found processors were

proudest of their craft when they could get the purest, most consistent batches. It is with this goal in mind

that the FRACTION FINDER was developed.

The ability to directly track molecules of interest during the process comes with a few key benefits:

●The data to improve purity and reduce by-products

●The information to improve process techniques and enhance process repeatability

●The ability to quickly train staff and have run traceability

What the FRACTION FINDER is not:

The FRACTION FINDER is not a quantitative measure. It provides qualitative process information that

directly tracks the relative concentration of Cannabinoids. It is Arometrix’s goal to amass enough spectral

data from the FRACTION FINDER to eventually be able to determine quantitative purity in the future.

The FRACTION FINDER cannot replace good laboratory practice and experience. The FRACTION FINDER’s

data, in combination with temperature, vacuum, good laboratory practice, and experience will help

technicians further perfect their craft.

Section 2: Fundamentals

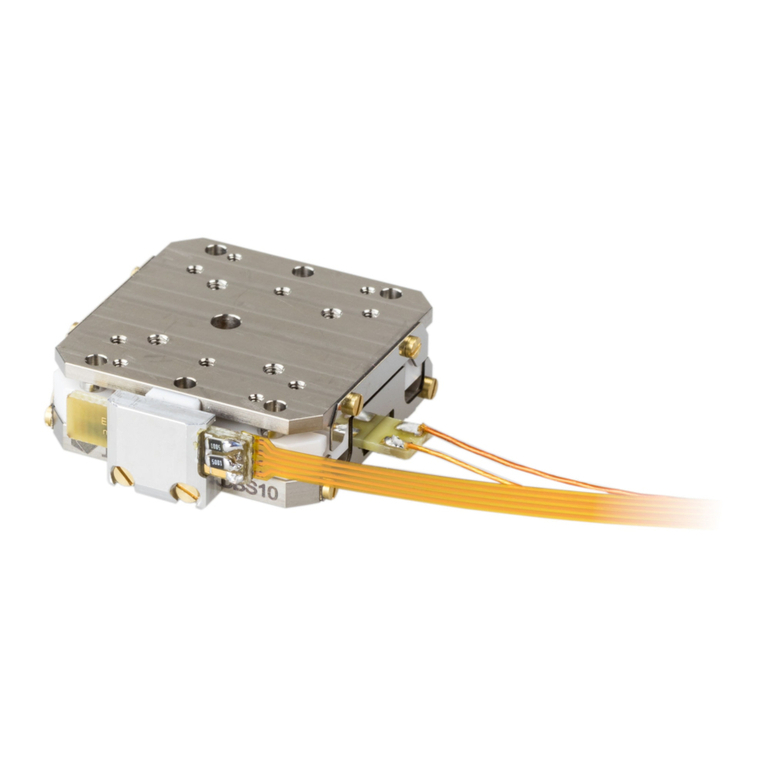

The FRACTION FINDER is composed of two key components: the sensor and the monitor.

Sensor:The sensor contains the “eyes” of the system”. The sensor is mounted on size 29 or 34 glass,

depending on the sensor size option ordered. Adapters are also available to install the sensor on smaller

glass, such as size 24 glass.

Monitor:The monitor contains the “brains” of the system. This 10” monitor consists of a compute

module that creates a visualization for the user where both flow and relative potency are deduced. The

monitor has a stand.

Note: This unit is intended for lab use. Care should be taken not to spill anything on it, as it is not waterproof.

Section 3: Unpacking and Inspecting

After the instrument is received, it should be carefully unpacked and inspected for damage during

shipment and to confirm that all components are present.

Each FRACTION FINDER 2018 - 2021 comes with:

●Fraction Finder Sensor (Size 29 or 34)

●Arometrix Monitor

●Pole mounting bracket screw

●Sensor Cable, USB

Arometrix, Inc. Sales@arometrix.com arometrix.com/resources

4

●Light-Blocking Tape

●International Power Supply

●Adapter (optional)

●Warranty Card

Each FRACTION FINDER 2022 and newer comes with:

●Fraction Finder Sensor (Size 29 or 34)

●Arometrix Monitor

●Sensor Cable, USB

●Light-Blocking Tape

●International Power Supply

●Adapter (optional)

Section 4: Installation

The equipment should be in a clean, dry environment for the best results. Care should be taken to avoid

any spillage.

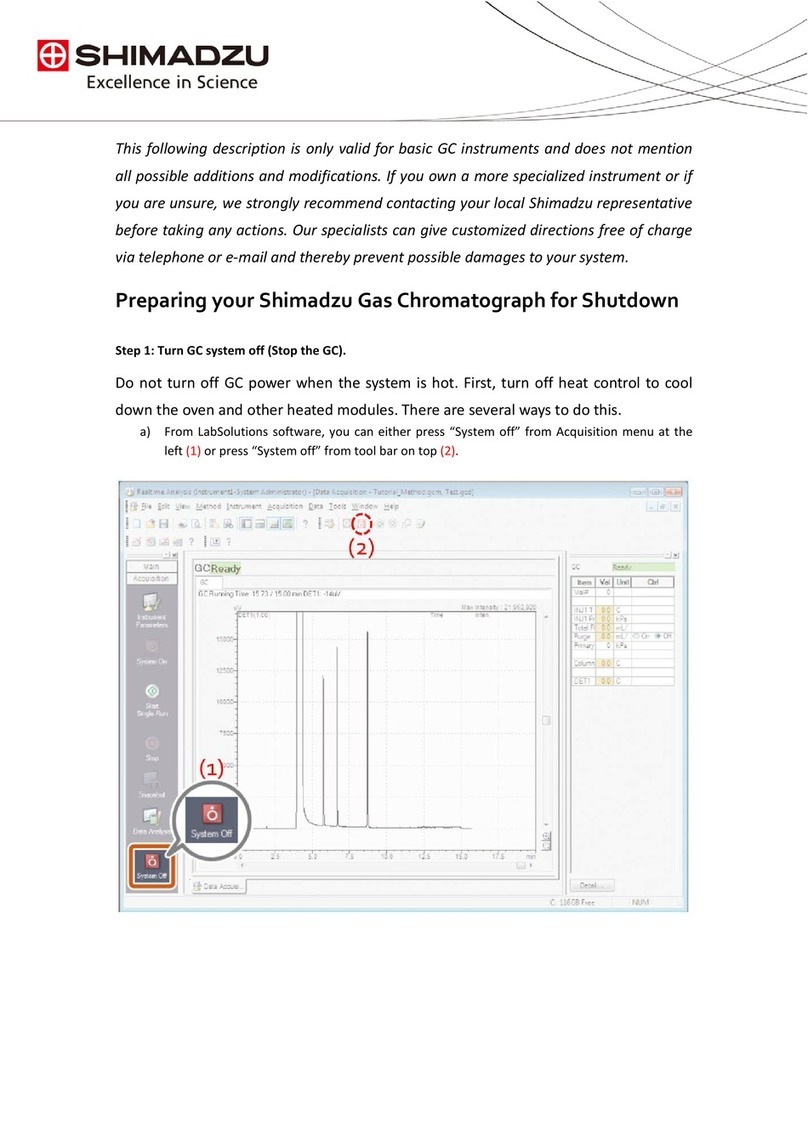

The Arometrix system was designed initially for short path distillation. Thus, the installation instructions in

this standard user manual focuses on how to operate the system for this specific application. If you are

using the system for another application, refer to our Application Notes on arometrix.com/resources.

1. Apply the light-blocking tape to the glassware apparatus, leaving an area for the sensor to be

installed. This is important as it will block ambient light from saturating your sensor’s readings.

2. Install the sensor with the thicker part of the sensor down. The sensor should be installed on the

condenser just before the cow as shown.

(1) Having the glass be of high quality will help increase the signal to noise ratio – which will

yield better information.

(2) The sensor fits on most glass, but in some cases may require an adapter; visit our website.

Arometrix, Inc. Sales@arometrix.com arometrix.com/resources

5

3. Insert the sensor cable into the back of the sensor.

4. Connect the other end of the sensor cable to the monitor. The sensor’s light will begin to “blink”,

indicating that it has turned on. Give the sensor ~2-5 minutes to boot up.

5. Mount the monitor.

6. Power the monitor.

7. The monitor will take a few seconds to turn. You will see splash screens, followed by the interface

screen.

8. Ensure that the Device Status and Server Status indicator on the bottom left-hand side of the

monitor are green – If not, make sure the cords are properly connected.

9. Ensure that the “Light On/Light Off” toggle button is turned on. The light above it should be green.

Section 5: Understanding the Interface

After installation, the system is ready for immediate operation.

Different Viewing Options

There are currently two viewing options: the Spectrum view and the Wavelength view. These display

options can be toggled between each other by tapping the “display” button (located in the top-left corner).

Spectrum View (Spectrograph)

What it does:This is an instantaneous representation of the current spectral state. It displays the current

background/ambient light corrected spectral measurement.

Important Note: The peak at 360-390nm is an internal excitation/reference peak (not a process indicator);

tap the small circle on the top-left corner of the graph to remove this peak

Understanding the Graph (X-Y Axis)

Arometrix, Inc. Sales@arometrix.com arometrix.com/resources

6

●X-axis = Wavelength (nm):The location of where the line shoots up (or fluoresces) indicates the

molecule(s) passing through; different molecules have different wavelength regions

●Y-axis = Intensity (counts): The height of this line, in general, indicates how much of that substance

is present at that moment relative to earlier.

Wavelength View

What it does: Displays and tracks the interpreted values from your measurement. This plot reduces the

raw data and shows you the “highlights” of the run. This view is especially useful for tracking particular

chemical oddities that occur at specific wavelengths.

Understanding the Graph (X-Y Axis)

●X-axis = Time (HH:MM:SS):As opposed to the Spectrum view, this tracks fractions as a function of

time.

●Y-axis = Intensity (AU): The height of this line indicates how much of that substance is present at

that moment relative to earlier. (Note: These are AU as in Arbitrary Units; this is not quantification

of potency.)

Setup Screen Tutorial

List of buttons:

A. Display: Toggles between the two viewing options (Spectrum View & Wavelength View)

Arometrix, Inc. Sales@arometrix.com arometrix.com/resources

7

B. Details: Expands the graph and removes the data on the right-hand side

C. Overlay: Traces or “overlays” a peak of interest so you can compare it to a future peak

D. Clear: Clears an “overlay” that you no longer want to track

E. Transfer: Transfers recorded run data to a flash drive

F. Reference Peak Remover: Removes the internal reference/excitation peak from Spectrum view

G. Auto-Zoom: Returns zoom view to normal. You can zoom with 1 finger by drawing a bounding box.

H. Home: Returns you to the Home if you are in Settings

I. Settings: Allows you to adjust settings, such as Auto Integration Time, Scans to Average, and the

Wavelength Tracker

J. Light on/off: Turns the light on. This toggles between states.

K. Record on/off: Turns the recording mode on. This toggles between states.

The following information is for 2021 models and older only:

L. Region 1-3 Checkboxes: For Wavelength View - By checking this box, it will populate the

Wavelength plot with the corresponding molecule tracking. For Spectrum View - By checking this

box, it will highlight the Spectrum plot with the region that molecule fluoresces at.

M. Region 2 Checkbox:See I.

N. Region 3 Checkbox:See I.

The following information is for the 2022 models and later:

O. Region 1-3 Checkboxes: For Wavelength View - These will automatically be checked and applied to

the Wavelength plot

Settings Tutorial

When you tap the Settings button, you will see:

●Wavelength Settings

●Set Integration Time

●Set Scans to Average

●Clock Settings

●System Data

Wavelength Settings

In this tab, you will see:

●Edit Wavelength 1

●Edit Wavelength 2

●Edit Wavelength 3

These correspond with the Region 1, Region 2, and Region 3 that are shown on the plots. When you press

one of these, you will see a Wavelength range. These will come preset with manufacturer’s defaults;

however, you can edit the From and To how you see fit. See below.

Arometrix, Inc. Sales@arometrix.com arometrix.com/resources

8

Click “Default” to return back to manufacturer default. Next to the “Default” button, you will see a

molecule dropdown. When you press the Molecule Indicator dropdown, you will see different molecule

tracking options. You can select any of them, or set your own “Custom” molecule and region. See below.

Set Integration Time

This is meant to enable “AID (Auto)” by clicking the checkbox in the bottom-left corner of the screen. Auto

integration ensures that the signal from the spectrometer is maximized. It is not recommended to

manually tune Integration Time, but it is feasible. See Appendix for more information on manual tuning.

Set Scans to Average

This sets how many optical readings the sensor takes before plotting and displaying a result. More

readings that are averaged imply less noise, but less information. Arometrix recommends that you select 5.

Clock Settings

This should be set during initial acquisition. Set the Date Settings and the Time Settings. Then, Submit.

System Data

This will display “Bytes Available”, “Bytes Used”, and “Bytes Total”. It will also show you % memory used,

and give you an option to “Clear Data”.

Section 6: General Procedure for Short-Path Distillation

The Arometrix system was designed initially for short path distillation. Thus, the general procedure in this

standard user manual focuses on how to operate the system for this specific application. If you are using

the system for another application, please refer to our Application Notes on arometrix.com/resources.

Arometrix, Inc. Sales@arometrix.com arometrix.com/resources

9

Overview

1) Set Up Distillation System and Install Fraction Finder Equipment (as detailed in Section 4)

2) Set Integration Time to Auto

3) Set Scans to Average to 5

4) Identify Transition from Heads to Main Body

5) Perform Flask Transfer & Let Distillation System Equilibrate

6) Identify Transition from Main Body to Tails

7) Perform Flask Transfer & Let Distillation System Equilibrate

8) Turn off Recording

Step 1) Set Up Distillation and Install Fraction Finder Equipment

1) Set up your short path distillation system as you usually would initially

2) Follow all steps in Section 4 Installation

a. Reminder: Ensure that the Device Status and Server Status indicator on the bottom of the

display are green.

b. Reminder: Ensure that the light is on. If the light is not on, turn it on and wait for the

indicator light above the button to turn green.

3) Let the distillation system reach desired vacuum temperature and pressure

Step 2) Set Integration Time to Auto

To set sensor Integration Time: Tap the Settings gear icon. Tap “Set Integration Time”. There is an AID

(Auto) checkbox on the bottom-left corner of the UI. Tap the checkbox - a check will appear, indicating that

auto-integration determination has been enabled. This is strongly recommended as it will auto-determine

an optimal integration time for the sensor throughout the entirety of the distillation. It is not

recommended to manually tune Integration Time, but it is feasible. See Appendix.

Step 3) Set Scans to Average to 5

To set sensor Scans to Average: Tap the Settings gear icon. Tap “Set Scans to Average”. A typical value

between 1 and 5 – It is strongly suggested that the scans to average is not set significantly larger than this

value.

Step 4) Identify Transition from Heads to Main Body

While you are in “Heads”, you should see ONE single peak at ~365 nm (x-axis) on the Spectrum view. This

is NOT a process indicator. This is the internal reference peak that the system uses.

Arometrix, Inc. Sales@arometrix.com arometrix.com/resources

10

Note: Arrow on graph is for illustration purposes only.

Depending on the software version that you are using, this peak can be removed by tapping a small button

on the UI. Once removed, during Heads, you should see NO peaks in the Spectrum view.

However, if you see MULTIPLE peaks, this means that either: You have bad light contamination from

lighting in the workspace (Solution: use the light-blocking tape) OR, if the peak is at 400-500 nm (x-axis

value) the column is probably not clean and contains a contaminate from a previous distillation (Solution:

Either stop the distillation and clean inside of glassware OR just make a note of it – it will likely be cleaned

when the vaporized Heads flow through the column).

If you switch to the Wavelength view, you will also see no fluorescence, as depicted in the image below.

If you would like to Record your run, and export the run data afterward, now would be an optimal time to

press the “Record” button. The circle above this button will turn green to indicate that it is recording.

Prior to the Main Body fraction, you will likely see a signal at around 420 nm. This is what is referred to as

“Fool’s Gold”. “Fool’s Gold” is an unidentified species that looks gold in color. Due to its golden hue, during

short-path distillation, it “fools” the operator to thinking that the desired Cannabinoid has appeared; but,

in actuality, it is not. The wavelength region for “Fool’s Gold” is 405 nm – 435 nm. The waveform for “Fool’s

Gold” is sharp. Refer to our Chemical Cheat Sheet for more information on this.

For the actual Heads to Main Body Transition, there are two separate methods for identifying this:

Arometrix, Inc. Sales@arometrix.com arometrix.com/resources

11

Option A - Spectrum View: The other indicator is that a broad peak shows up in the Spectrum plot

between 440-450nm. An example plot is shown below; keep in mind peak location and intensity may vary.

See our “Chemical Cheat Sheet” to learn about where and how each molecule fluoresces on the unit.

Arometrix recommends that you use the Spectrum plot for an absolute indicator of the Heads to main

body transition.

Option B - Wavelength View: This view will show that there is a big peak in the value of the wavelength

plot. An example plot is shown below. The Wavelength View is recommended to identify when the

distillation is transferring from Heads to Main Body.

Step 5) Perform Flask Transfer & Let Distillation System Equilibrate

1) Once you’ve entered Main Body, proceed as you typically would with a flask transfer.

a. It is advised that the Heads be allowed to distill for ~10 minutes before performing a flask

to ensure that no solvents contaminate the Main Body.

b. There is no need to turn off or hit the clear button on the FRACTION FINDER, unless you

want to.

2) After flask transfer, let the system come to its equilibrated point (let pressure and temperature

become relatively constant) before using the FRACTION FINDER

a. Keep in mind that the signal will be very low and all ambient lighting effects will greatly

increase

b. Equilibration time will depend on system size. A 5L SPD can take 5-10 mins. A 10L SPD can

be 10-15 minute. Mantle quality and pump quality are also factors for equilibration time.

Arometrix, Inc. Sales@arometrix.com arometrix.com/resources

12

Step 6) Identify Transition from Main Body to Tails

1) After 20 minutes from the flask transfer from Heads to the Main Body, the signal will become more

stable

2) Check the Wavelength View

3) A sharp increase of the signal at the beginning will likely be shown, followed by a sharp drop-off of

the signal to a stable moderate level

a. This initial increase is very concreted Main Body initially coming through the system as well

as any oxidized/degraded fluid that may have been generated during the vacuum release

while performing a flask transfer

4) This signal will likely stay constant for the next 1 – 1.5 hours, then will slowly start to raise. An

example plot is shown below.

5) The constant increase or significant increase of signal at this point indicates that the distillation

may be entering Tails, but the signal also could vary slightly with:

a. Significant changes in vacuum pressure

b. Significant changes in flow rate

c. Background light gets brighter

6) If a raise is observed that does not seem to track with the three outlined changes above, the

distillation has entered Tails

For the Main Body to Tails Transition, there are two separate methods for identifying this:

Option A - Spectrum View: This view will show that there is a peak shift to the right, with the peak

centered at around 490-510nm. An example plot is shown below. Note: Our “Degradates” indicator is

equivalent to the Tails fraction. Refer to our Chemical Cheat Sheet for more information on this.

Option B - Wavelength View: This view will show that there is a sharp increase in the value of the

wavelength plot. An example plot is shown below. This view is recommended for this change, as well.

Arometrix, Inc. Sales@arometrix.com arometrix.com/resources

13

Note: Intensity and trends may vary. The important thing is the signal starts increasing.

Step 7) Perform Flask Transfer

Once the Tails are identified, perform a flask transfer as per usual. Keep in mind that the signal will be very

low and all ambient lighting effects will greatly increase

2018-2021 Fraction Finder

Step 8) Turn Off Recording (optional) If you record your run, tap “Record Off”. The circle above this button

will turn red. Then, plug in a USB stick to the monitor. Press “Transfer” to transfer your run data to a USB

stick. It will upload a file in CSV format, easy to work with in Excel.

2022 and Later Fraction Finders

Step 8) Turn Off Recording (optional) If you recorded your run with an sd card installed, tap “Record Off”.

The Record button will turn red. Then, remove the sd card and transfer the data via the SD card reader.

Files will upload in CSV format, easy to work with in Excel.

Section 7: Issues

1) If the signal is an abnormally low signal, a few things should be checked:

a. Ensure that the alignment of the FRACTION FINDER sensor is correct. This can be done by

trying to align the screw in the “light shield” and the top of the light shield with the cooling

water port of the condenser; if they are aligned, the alignment is optimal. The “light

shield” is the half-circle piece of hardware adjacent to the light source.

b. Ensure that the integration time is set correctly by using the AID (Auto Integration) AUTO in

Settings. The checkbox should be checked off.

c. Ensure that the Scans to Average is set to 5.

d. Are you distilling THC? Our THC Indicator is a short, broad signal; however, it is still easily

discernible. See our Chemical Cheat Sheet.

e. If none of the above seem to be the origin of the problem, please take a photo of both

your spectrum plot and your wavelength plot, then email brains@arometrix.com.

Optimal Sensor and Light-Blocking Tape Orientation

Arometrix, Inc. Sales@arometrix.com arometrix.com/resources

14

2) If the signal looks sporadic and very abnormal, a few things should be checked:

a. If it is right after a flask transfer, wait a few minutes – this is normal behavior

b. If the vacuum pressure is still changing quickly, wait for the pressure to become more

constant

c. If the boiling flask is heating significantly, wait for the boiling flask temperature to become

more constant

d. The issue could be attributed to background light

i. Use the light-blocking tape provided in the kit

e. Ensure that the integration time is set correctly by either using the AID AUTO or following

the procedure outlined in step 5

f. Increase the scans to average

i. This should not be set significantly higher than 5 - keep the value below 15

g. If none of the above are the problem – ensure that liquid is still flowing

h. If none of the above seem to be the origin of the problem, please take a photo of both

your spectrum plot and your wavelength plot and contact customer service by emailing

brains@arometrix.com or submitting the Support Request form on our website

3) If the system is not detecting the sensor (bottom left light on panel is red or yellow)

a. If the system was turned on, give the system up to 5 minutes, it may detect

b. Ensure that all cables are connected securely – especially the cable connecting the monitor

unit to the sensor

i. It may be easier just to disconnect and reconnect the cables from the monitor unit

and the sensor unit

c. Try identifying and using a new source of power to power the Fraction Finder monitor

d. If none of the above seem to be the origin of the problem, please take a photo of both

your spectrum plot and your wavelength plot and email brains@arometrix.com.

4) Warnings about safe operating conditions for the FRACTION FINDER:

a. Currently, the FRACTION FINDER is specified to work up to 100 degrees Celsius. Please do

not raise your condenser fluid temperature above this. Should this be a part of your SOP,

then order the “Hot Tech Adapter” from Arometrix.com. This will relocate the sensor to

just prior to the collection flask.

b. The FRACTION FINDER housing (both the sensor and the monitor unit) are sensitive to

distillate and extract, to increase sensor lifetime and reduce the likelihood of damage:

i. Wipe down the outside of the glass that the FRACTION FINDER will clamp onto

before installing the sensor with ethanol, isopropanol, or another alcohol. DO NOT

USE ACETONE | WARNING: ENSURE THAT GLASSWARE IS NOT HOT!

Arometrix, Inc. Sales@arometrix.com arometrix.com/resources

15

ii. If an accidental spill occurs, try to wipe it off the sensor/monitor with a damp, not

soaked, cloth/towel as quickly as possible. Dry off the area immediately afterward.

Other issues and suggestions:

1) We have all of our Fraction Finder resources (including different application notes and our

Chemical Cheat Sheet) available at arometrix.com/resources.

2) We are constantly working to fix any issues with the system, and appreciate you reporting any

abnormal behavior, we will not leave you hanging and will address any issues you have ASAP.

3) If you find anything in this manual confusing or unclear, please email us at brains@arometrix.com;

we are more than happy to assist you, and do our best to do so in a timely manner.

4) If you want to see something new in the software please let us know and give your suggestion, we

strive to make the FRACTION FINDER the tool that works for you!

Section 8: Software Update Instructions

At Arometrix, we strive to tailor-make all our products to our customers' needs. As we advance our

algorithms, add features, fix bugs, etc., we release software/firmware updates. These are field-updatable.

If you own a FRACTION FINDER, you can download our latest, free Firmware update to your software in the

field: Version 1.2.4 - (if you do not already have it). This update will make FRACTION FINDER systems more

cohesive and user-friendly. Please visit arometrix.com/software to update your software.

Section 9: Optical Measurement

The FRACTION FINDER displays optical information in AU (arbitrary intensity units), named to highlight the

fact that the unit is for reference, indication, and to assess trends. It is not currently for quantitative

analysis. Quantitative measurement is a number that represents a characteristic in known, well-understood

units. For example, your speedometer reads a quantitative number – speed. You know how fast you are

going based on that number. Qualitative measurement lacks the reference of a number. The FRACTION

FINDER gives qualitative measurement – and is used to assess trends, not absolute potency.

Section 10: Appendix

Manually Tuning Integration/Exposure Time -It is highly recommended to use the AID as the AID

algorithm will do all the adjustment autonomously. However, manual setting is feasible. Here is how…

Manually Setting Integration Time for Heads - Tune the Integration Time based on your desired parameters

1. Tune the exposure time so that the maximum intensity value (y-axis) is between 500-800 AU

a. The exposure time is pseudo-linear to the intensity (i.e. if the exposure time is doubled,

the intensity will approximately double; if the exposure time is halved, the intensity will

also approximately be halved)

b. The exposure time for the Heads typically is very small – the exposure time probably will

not be above 2 ms (2000 µs on exposure time setting panel), and may be lower than 0.1

ms (100 µs on exposure time setting panel)

c. WARNING: The update time for the plot will increase with increased exposure time and

decrease with decreased exposure time. Distillation is a slow process, so this will not be an

issue

Arometrix, Inc. Sales@arometrix.com arometrix.com/resources

16

i. It is more important that there is a good signal than to have a fast update speed,

so tuning to higher exposure times (as long as the intensity does NOT go above

800 AU – y-axis value), will ensure that the unit will work as intended.

Manually Setting Integration Time for Main Body

1) Go to the Spectrum tab

a. If the maximum signal value is lower than 500 AU or above 850 AU

i. Hit the Light On/Off button to turn light off

ii. Wait for a new scan of the background light in the room

iii. If the maximum value of this spectra is above 700 AU:

1. Adjust the exposure time so that this value is less than 700 AU by

decreasing it

2. The exposure time is pseudo-linear to the intensity

iv. Hit the Light On/Off button to turn light on

2) For the next ~20 minutes, the exposure time will need to be adjusted as the signal change

a. Factors that increase how often it will need to be adjusted are:

i. The darkness of the distillate (darker increase frequency of exposure time

adjustment)

ii. Turbulent flow rate (increases the of frequency exposure time adjustment up to a

point, then will not have an effect)

1. This is more of an issue for Tails than the Main Body

iii. Background light (more ambient/background light will increase the frequency of

adjustment; higher ambient/background light will also reduce the overall signal)

Section 11: Terms and Conditions

TERMS OF USE, LIMITED WARRANTY & LIABILITY WAIVER

TERMS OF USE, LIMITED WARRANTY, and LIABILITY WAIVER

Arometrix offers all of its products with the following terms and conditions and notices as follows. By accepting and/or using an Arometrix product,

you hereby acknowledge and agree to the following terms and conditions, and acceptance of these terms and conditions are a condition precedent

to any purchase/sale agreement between you and Arometrix. YOU MAY NOT ORDER OR OBTAIN PRODUCTS OR SERVICES FROM AROMETRIX IF

YOU (A) DO NOT AGREE TO THESE TERMS, OR (B) ARE NOT THE OLDER OF (i) AT LEAST 18 YEARS OF AGE OR (ii) LEGAL AGE TO FORM A BINDING

CONTRACT WITH AROMETRIX.

EXCLUSIVE OBLIGATION: The Arometrix product you are purchasing has been designed for a specific use within a set of suitable operating

conditions, as set forth in its User Manual, or as indicated otherwise by Arometrix. Any use of the Arometrix Product for any purpose or under any

conditions, other than those specified, shall render any limited warranty void, and shall expressly invalidate any liability of Arometrix for damages

as a result of such misuse.

USER LIMITATION: You may not modify, copy, distribute, transmit, display, perform, reproduce, publish, license, create derivative works from,

transfer, or sell, any information, software, products or services obtained from or created by Arometrix to any third party, without the express

written consent of Arometrix to do otherwise. Any violation of this provision shall give rise to an indemnification of Arometrix by you, for any third

party claims arising out of such violation.

THIRTY (30) DAY LIMITED WARRANTY: All Arometrix products are warranted against any manufacturing defect for a period of thirty (30) days from

the date of purchase, unless such product is a custom-work for you and not a standard Arometrix product. This limited warranty extends only to the

original purchaser of the Arometrix products. It does not extend to any subsequent or other owner or transferee of the product. The responsibility

of Arometrix for defective products is limited to repair, replacement or refund as set forth in this warranty statement. Any product qualifying as a

custom-work shall not be warranted against any defects for any purpose, and your acceptance of such custom-work shall relieve Arometrix of any

liability for any purpose. WITH THE EXCEPTION OF THE LIMITED WARRANTY ABOVE, YOU AGREE ANY Arometrix PRODUCT IS PROVIDED AS IS,

EXCLUSIVE OF ANY WARRANTY, INCLUDING, WITHOUT LIMITATION, ANY IMPLIED WARRANTY OF MERCHANTABILITY, FITNESS FOR A PARTICULAR

PURPOSE, NON-INFRINGEMENT, OR ANY OTHER WARRANTY, EXPRESSED OR IMPLIED.

LIMITATION OF LIABILITY: You agree and acknowledge, Arometrix shall have no liability to you whatsoever for any direct, indirect, punitive,

incidental, special consequential damages arising out of or connected with the use or misuse of its products. In particular, given the nature of

Arometrix products, you agree and acknowledge, under no circumstances whatsoever shall Arometrix be liable to you for any consequential

Arometrix, Inc. Sales@arometrix.com arometrix.com/resources

17

damages for damage to any non- Arometrix product or service, arising from the failure, use or misuse of a Arometrix product, including, but not

limited to, any vacuum system, engine, vehicle, factory, or the like. In the event, a court of law with proper jurisdiction finds Arometrix liable to

you for any purpose, you agree and acknowledge Arometrix’s maximum liability shall not exceed the purchase price of one unit of product giving

rise to such liability, or $250.00, whichever is greater.

ENTIRE OBLIGATION: These terms and conditions express the entire obligation of Arometrix with respect to its products. If any part of these terms

and conditions are deemed void, invalid, unenforceable or illegal, including, but not limited to, the warranty disclaimers, liability disclaimers and

liability limitations set forth above, then the unenforceable clause or sentence may be disregarded with the remainder of these terms and

conditions valid and enforced. In the event the unenforceable clause or sentence leaves a void in these terms and conditions, a provision closely

matching the intent of the unenforceable provision should be deemed inherent within these terms and conditions, slightly modified to render such

provision valid and enforceable.

GENERAL: These terms and conditions are governed by the laws of the State of New Jersey, USA. All claims and disputes arising under or relating to

this Agreement are to be settled by binding arbitration in the state of New Jersey. An award of arbitration may be confirmed in a court of

competent jurisdiction. Use of this product is unauthorized in any jurisdiction that does not give effect to all provisions of these terms and

conditions.

MODIFICATION OF TERMS AND CONDITIONS: Arometrix reserves the right to change the terms, conditions, and notices under which their

products are offered.

Arometrix, Inc. Sales@arometrix.com arometrix.com/resources

Other manuals for FRACTION FINDER

1

Table of contents

Other Arometrix Laboratory Equipment manuals

Popular Laboratory Equipment manuals by other brands

Shimadzu

Shimadzu GC quick start guide

Hinds Instruments

Hinds Instruments Exicor Gen5 user manual

Hettich

Hettich ROTINA 420 operating instructions

OHAUS

OHAUS ACHIEVER e-A51ST020 user guide

Thermo Scientific

Thermo Scientific Vanquish Charger operating manual

Biotage

Biotage Extrahera LV-200 Installation checklist