2. Replace safety valve steps

Usage Notice:These repairs may only be carried out by qualified personnel.Unless you are a

professional talent,otherwise,avoid electric shock, equipment failure,be sure to check the manual,

and according to the instructions for maintenance,at the same time,the manual has provided the

professional staff with maintenance methods as much as possible.

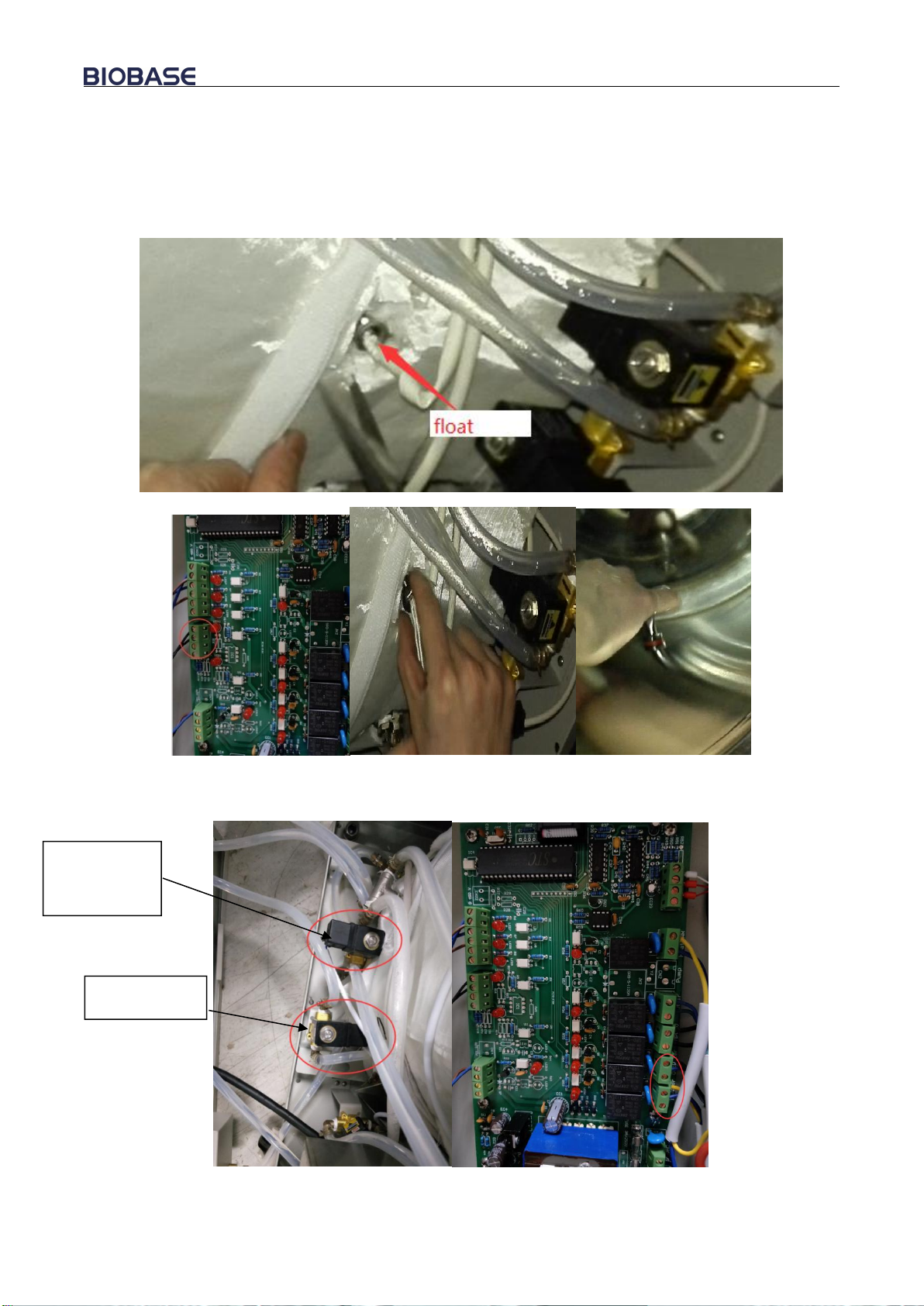

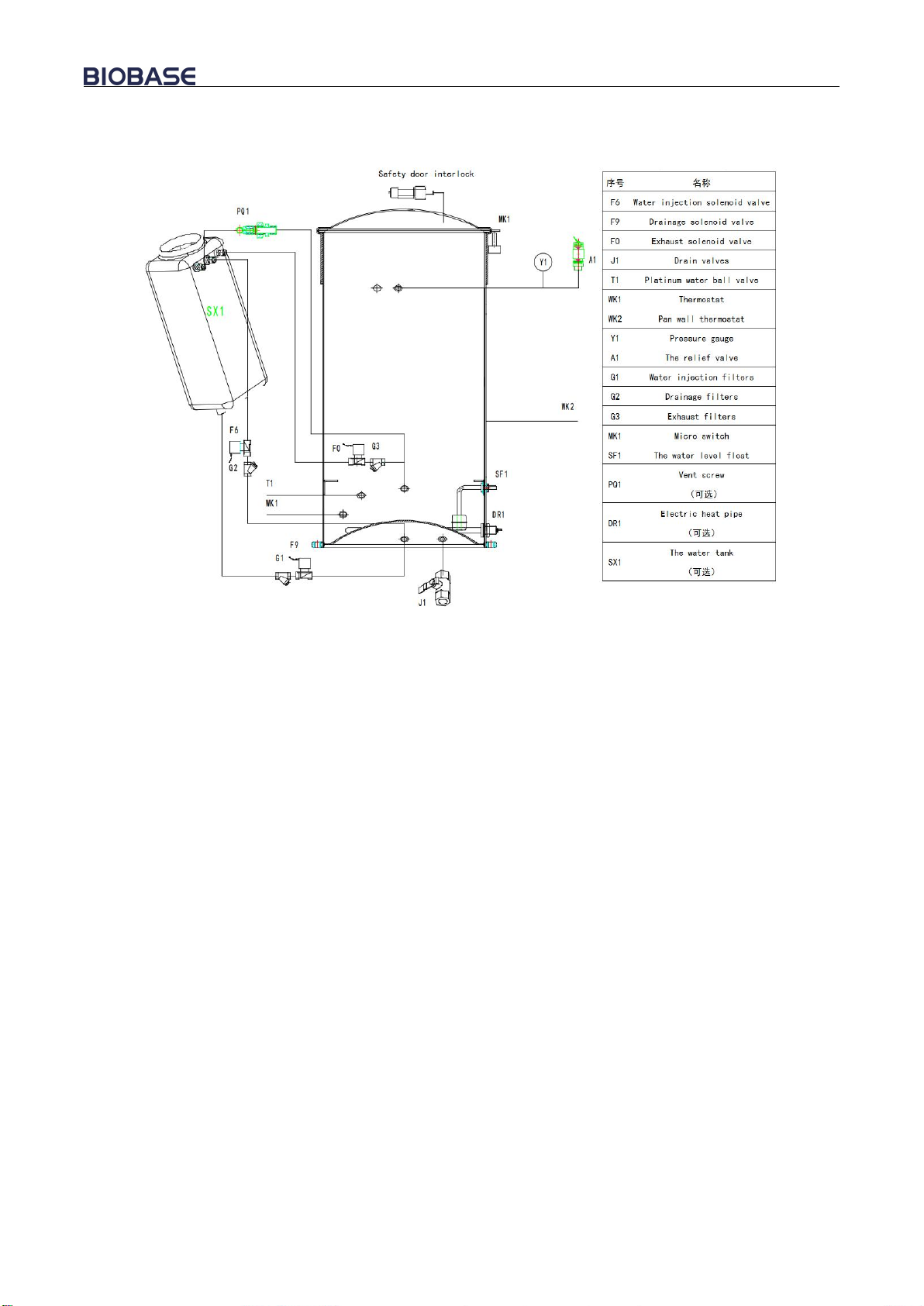

1)It is located above the rear of the device。

2)Remove safety valve retainer screw, remove the safety valve from the safety valve seat.

3)Replace it with a qualified safety valve. Test the sterilization process.

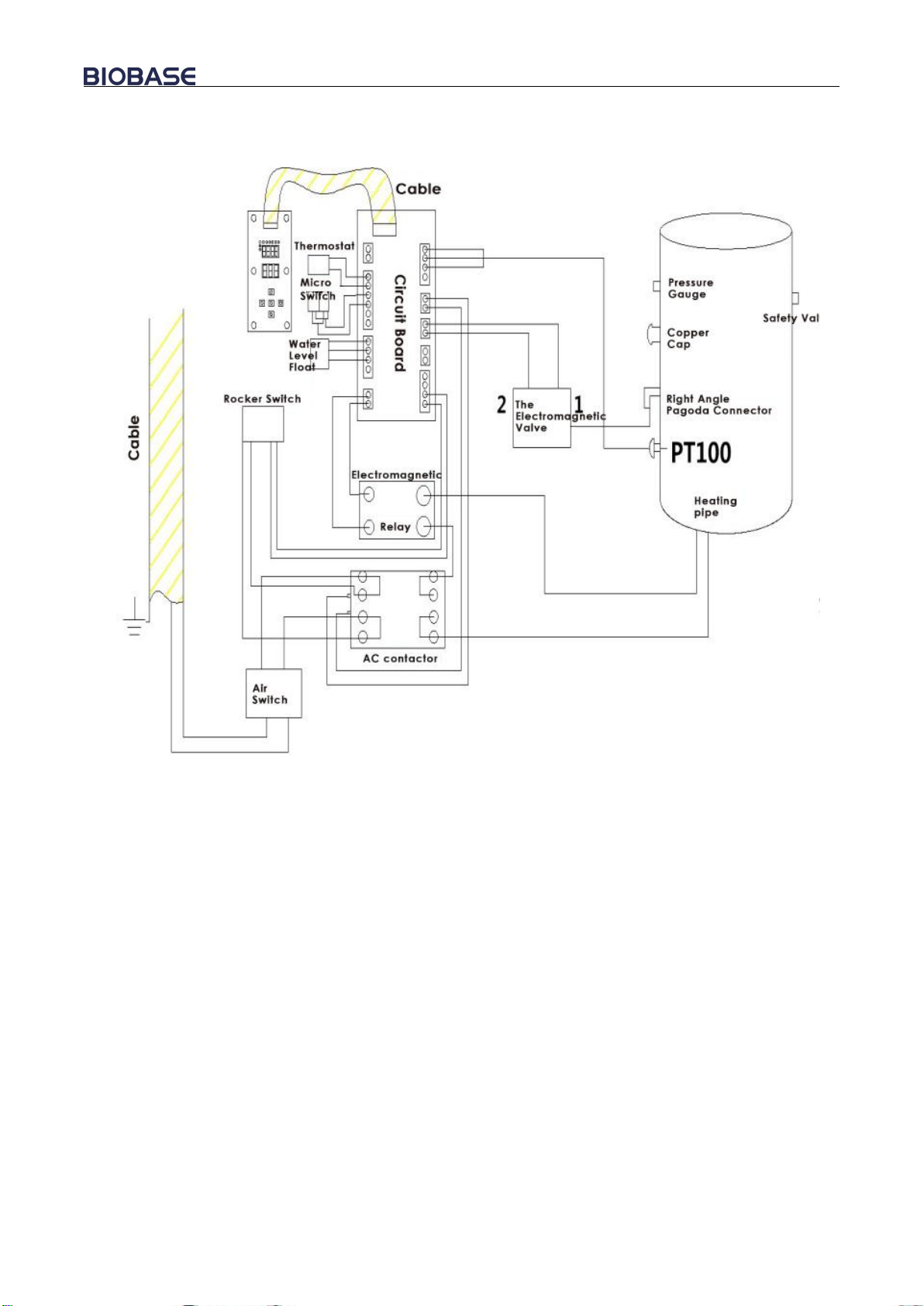

3. Thermostat

Located inside the device. The sterilizer is equipped with a thermostat. It can maintain a constant

temperature by turning the power on and off during the heating and sterilization phases. Usually used

as a temperature alarm device. If the pot temperature exceeds the allowable value, the

thermostat

automatically turns off the heater.

When the pot temperature dropped below the allowable value, the thermostat automatically

connected.

4. Replace thermostat steps

Before this operation, cut off the power and make sure there is no pressure inside the sterilizer.

1)Remove the thermostat wiring on the main circuit board。

2)Put the device on the ground.

3)Remove the thermostat at the bottom of the pan。

4)Remove the thermostat probe attached to the heating tube.

5)Replace the damaged thermostat with a new thermostat, The location of the new thermostat to be

replaced with the location of the thermostat coincide, and wiring。

6)Lift the device.

7)Test all the work process.

5. Replace the heating tubes step

Before this operation, cut off the power and make sure there is no pressure inside the sterilizer.

1)Put the device on the ground.

2)Remove the wiring from the heater on the bottom of the pot.

3)Loosen the captive screws on the heater.

4)Replace the damaged heater with a new one,The position of the new heater should match the

position of the heater to be replaced and be wired.

5)Lift the device.

6)Test all the work process.