13

Before the rst use, go through a sanitization procedure by

scanning the specic barcode and following the instructions

on the screen (details in the maintenance section of this user

guide on page 30).

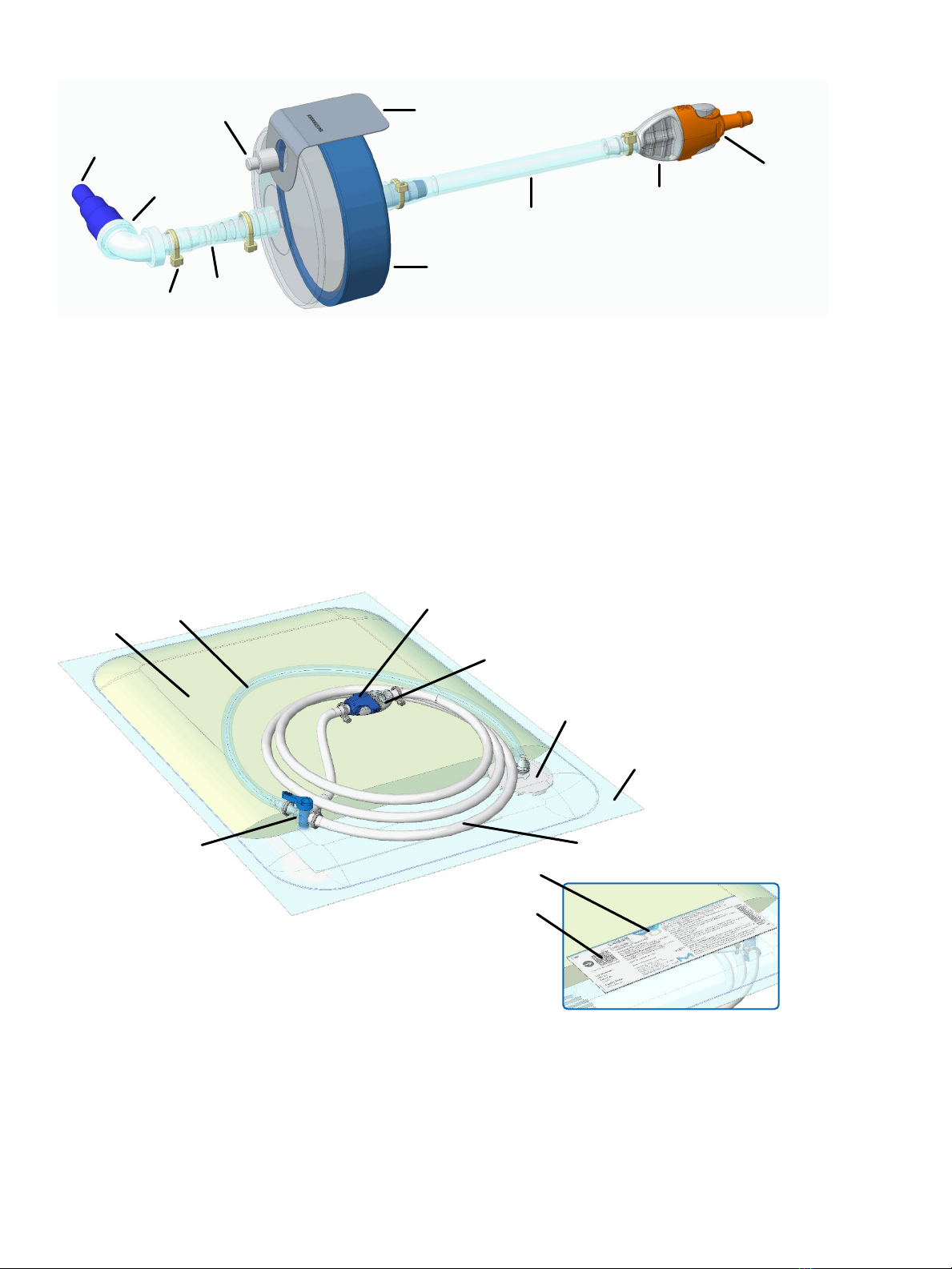

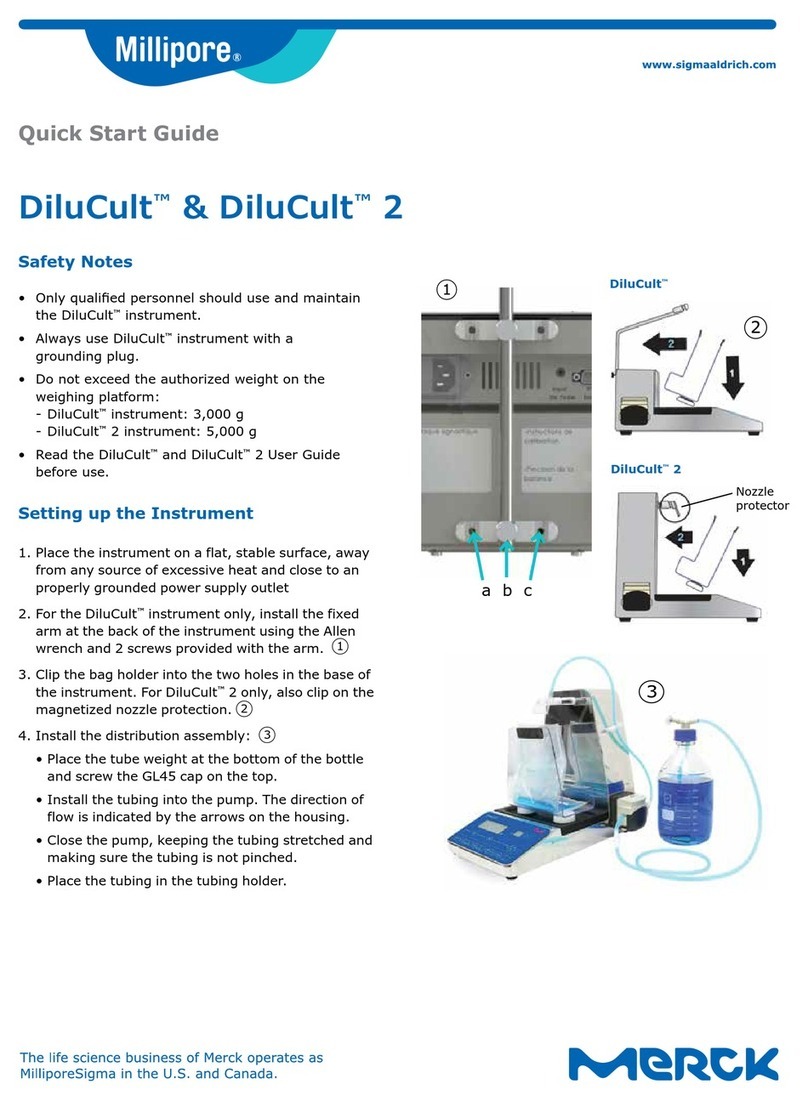

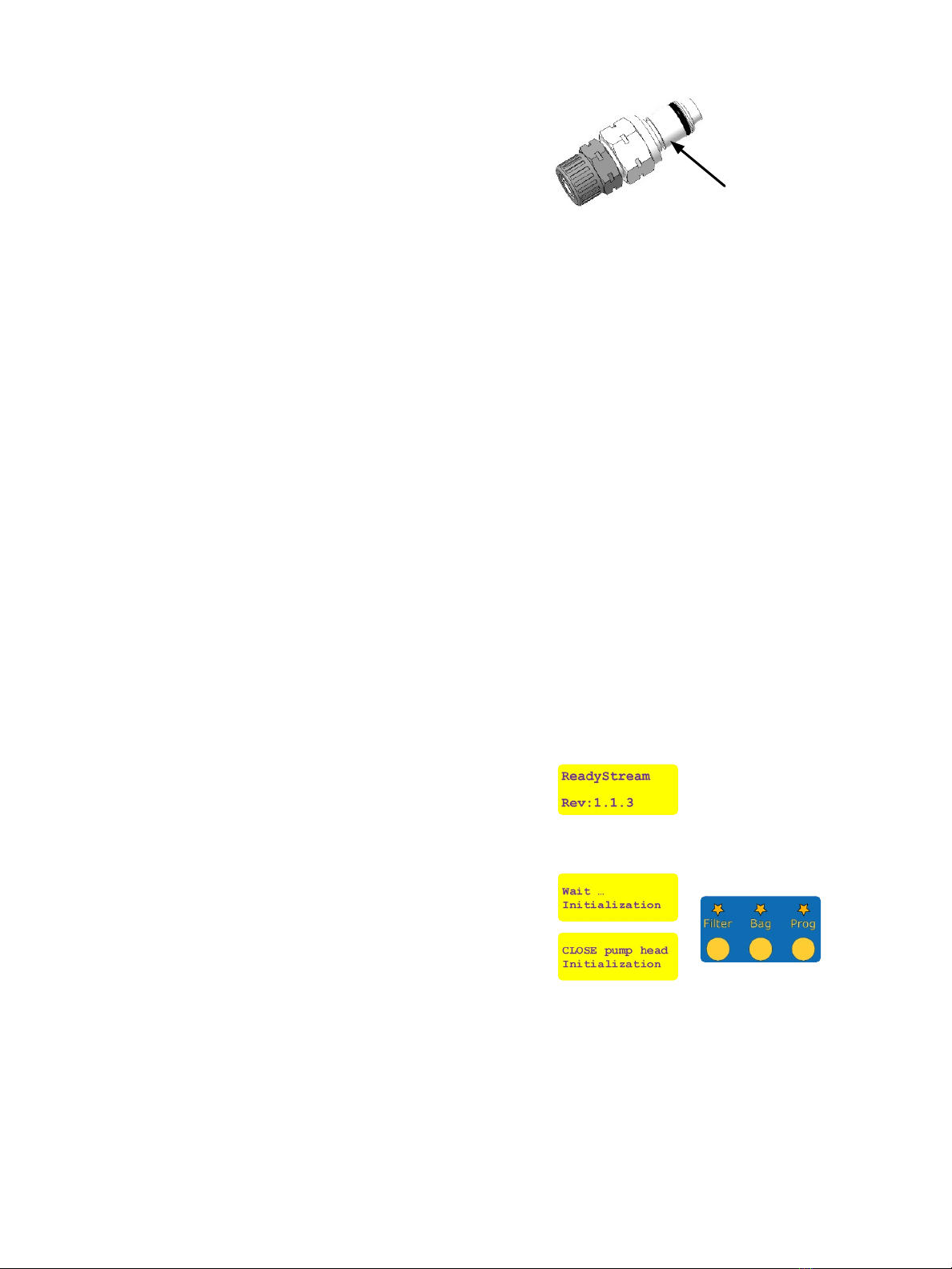

Connect the water inlet tubing to the instrument on the

connector on the left side (Figure 2, L1). Adapt the extremity

of the water inlet tubing to the deionized water faucet using

the required adaptors (standard mating CPC coupling body

for the connection to the PLCD200M8 connector on the inlet

water tubing, not provided). Alternatively, if no deionized water

production system is available in the laboratory, the water inlet

tubing can be inserted in a deionized water container. Use a tube

weight (not provided).

• If using a container, ensure that the water inlet

tubing remains in the container during dispensing,

and regularly check the level of the remaining

water to prevent the instrument from running

without water.

• Ensure the water is free of particles >200 µm that

may damage the system and reduce the lifetime

of the lter. If needed, install the provided mesh

strainer on the inlet tubing, respecting the ow

direction indicated by the arrow on the body.

Replace the strainer mesh once a year.

• Damage can occur if the system runs without

water.

• Verify that the pressure, ow rate and temperature

of the deionized water loop are within the range

of the operational conditions of the ReadyStream®

instrument. Notably, if several instruments are

connected to the water loop, ensure the ow rate is

sucient to allow the ReadyStream®media unit to

dispense at the required ow rate.

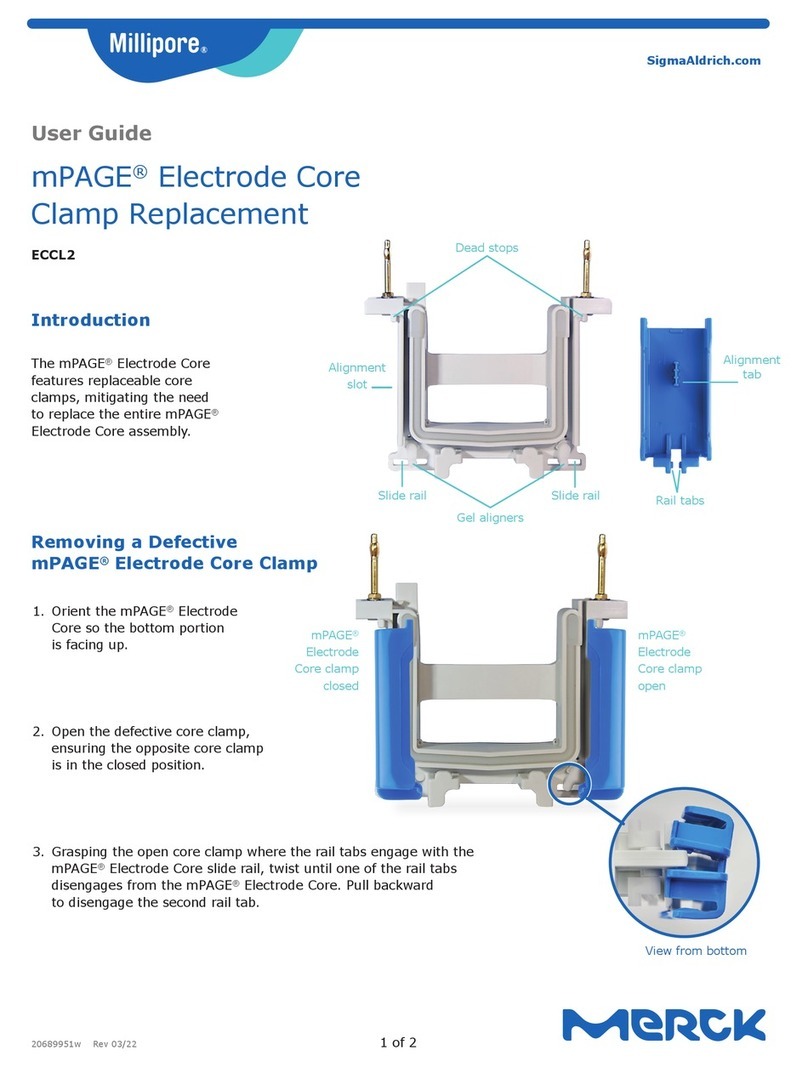

Powering the instrument ON and system

initialization

Connect the power cord to the back connector (Figure 1, B3) and

to a wall socket. The cable must be easy to unplug in the unlikely

event of an issue with the instrument.

Use the switch on the back, right side of the media preparation

unit, to power the instrument (Figure 2, R2).

The software revision is displayed, and all the LEDs are

highlighted for 5 seconds.

Press the ON/OFF button on the media dispensing unit to start

and initialize the instrument.

When starting the instrument, the peristaltic pump must be

closed for initialization. If not, the user will be prompted to close

the pump head, and the “Filter”, “Bag” and “Prog” LEDs will

blink in orange.

• During initialization do not attempt to open the

pump head.

• In case the instrument was not shut down properly,

the stopcock actuator (Figure 1, F3) will also turn to

the home position. Do not touch the moving part.

• In order to expand the battery lifetime of the

media unit, it is recommended to leave the main

power switch turned on and keep the instrument in

sleep mode by using the “ON/OFF” button on the

dispensing unit.

!

!

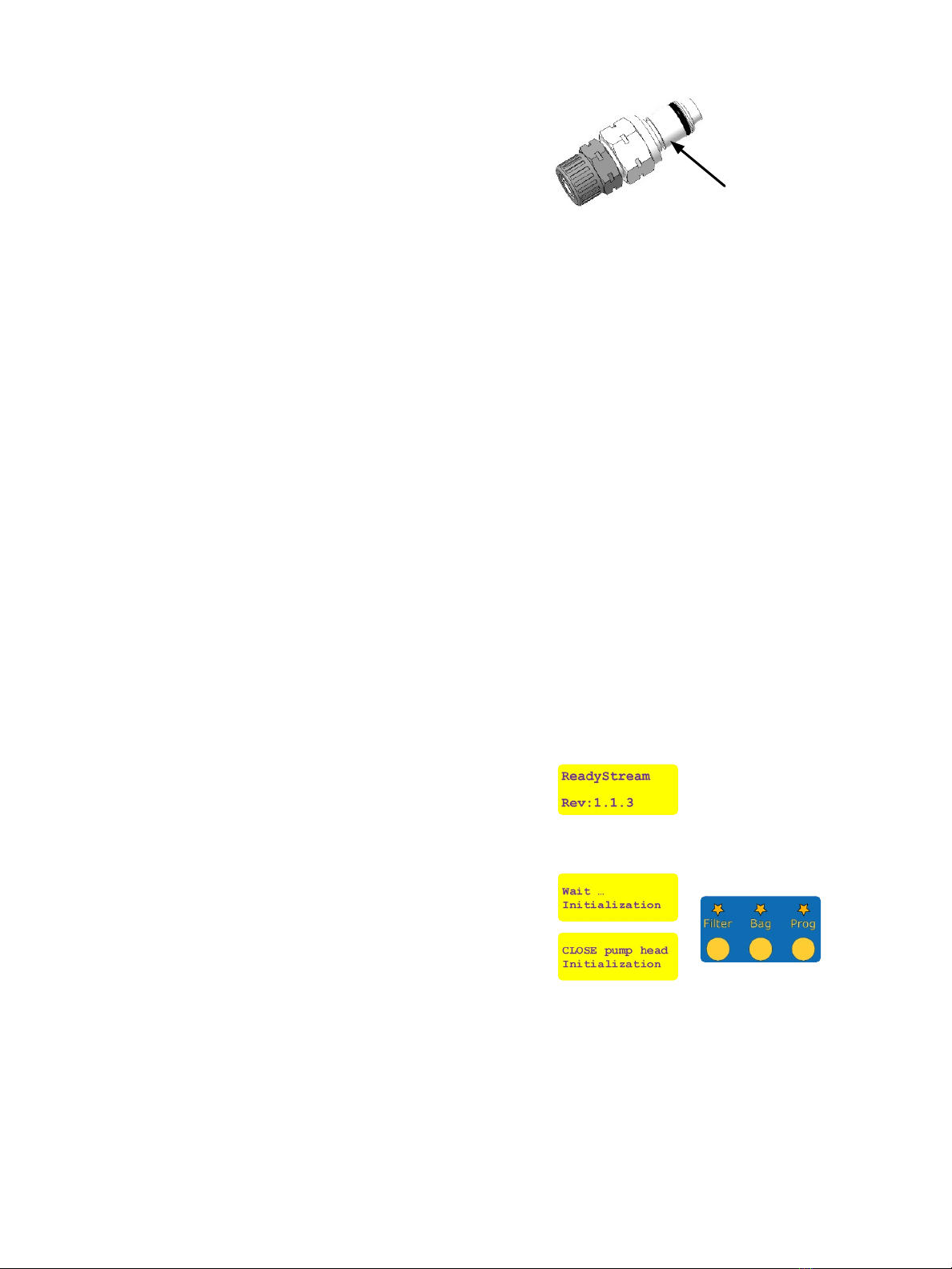

Quick connector

PLCD200M8