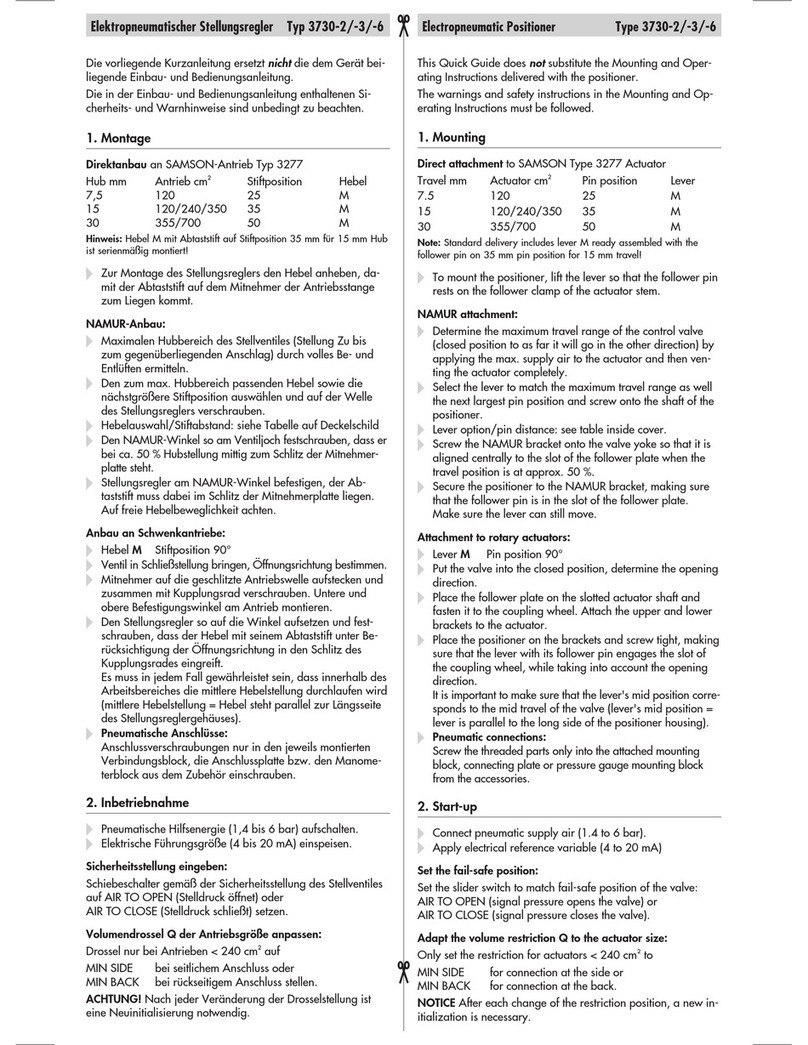

1 Design and principle of

operation

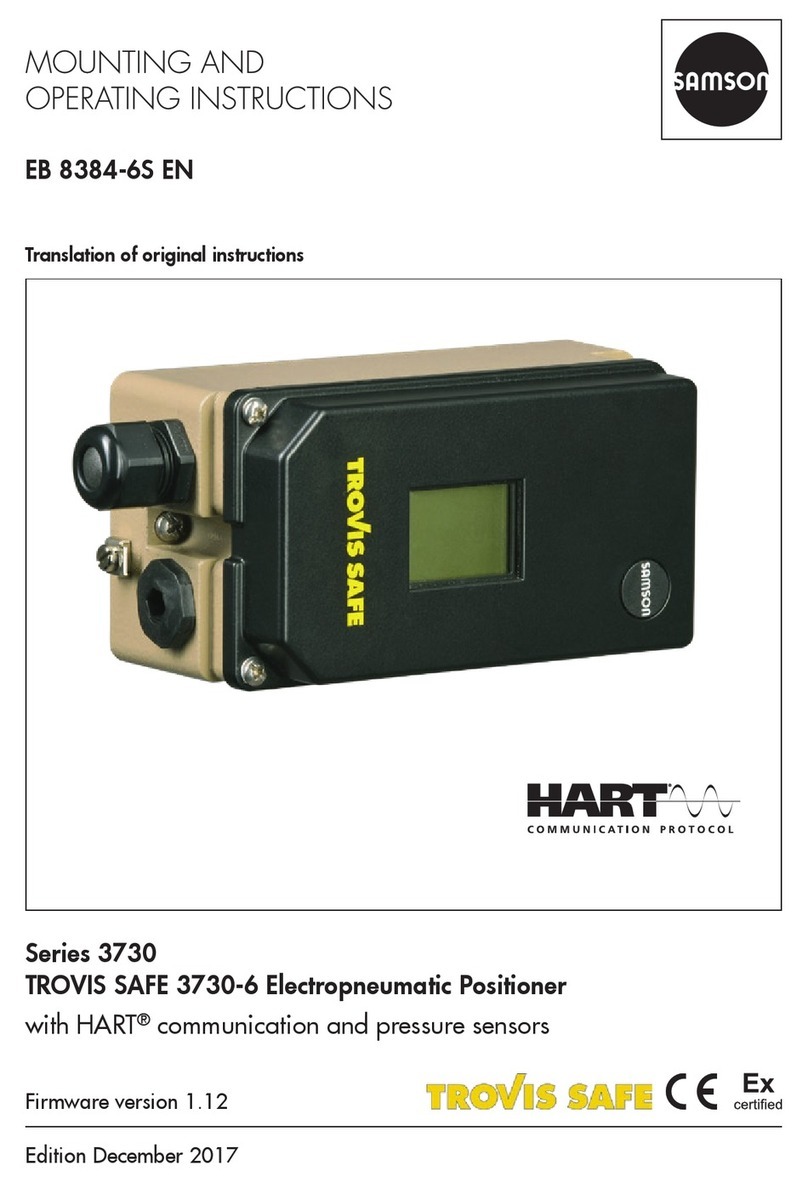

The electropneumatic Ex d positioner is

mounted to pneumatic control valves and is

used to assign the valve position (controlled

variable x) to the control signal (reference

variable w). The DC control signal received

from a control unit is compared to the travel

or rotational angle of the control valve and

the corresponding signal pressure (output

variable y) is issued.

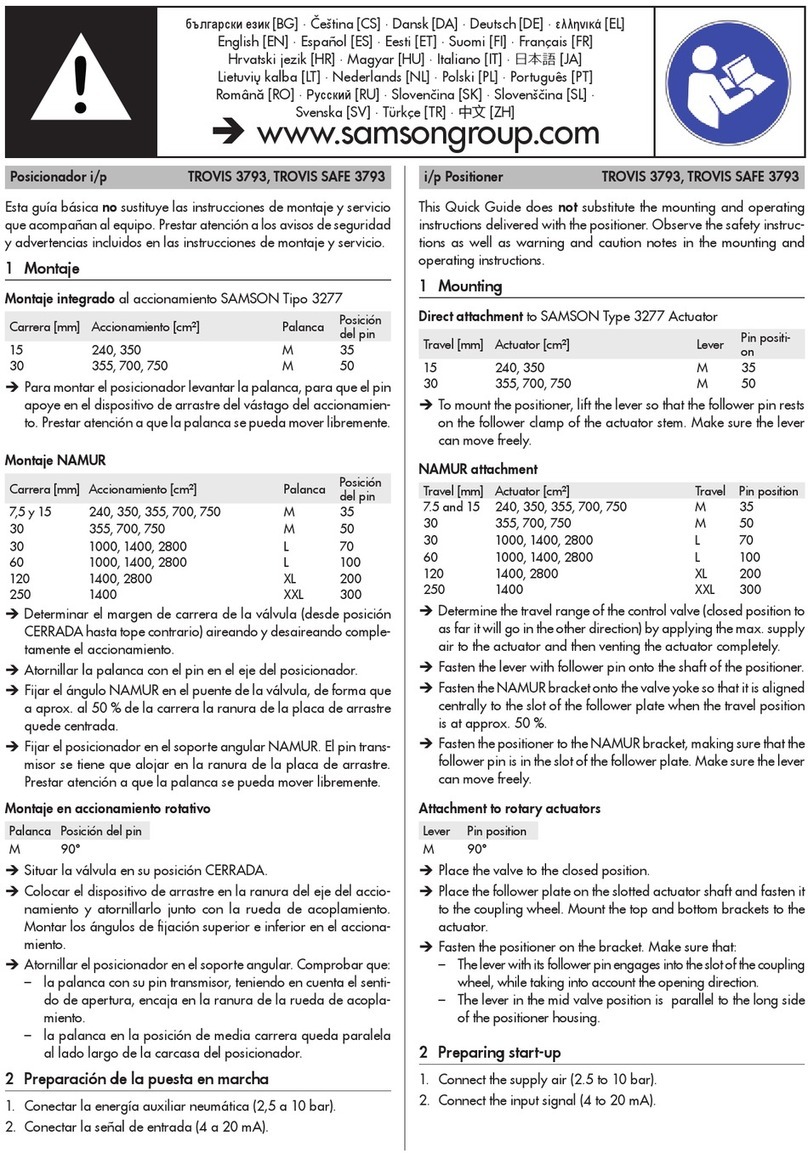

The positioner is designed depending on the

corresponding accessories for direct attach-

ment to Type 3277 Actuators or for attach-

ment to actuators according to IEC 60534-6

(NAMUR).

Additionally, a coupling wheel included in

the accessories is required to transfer the ro-

tary motion for rotary actuators according to

VDI/VDE 3845.

Springless rotary actuators require a revers-

ing amplifier included in the accessories to

permit the powered operation in either di-

rection.

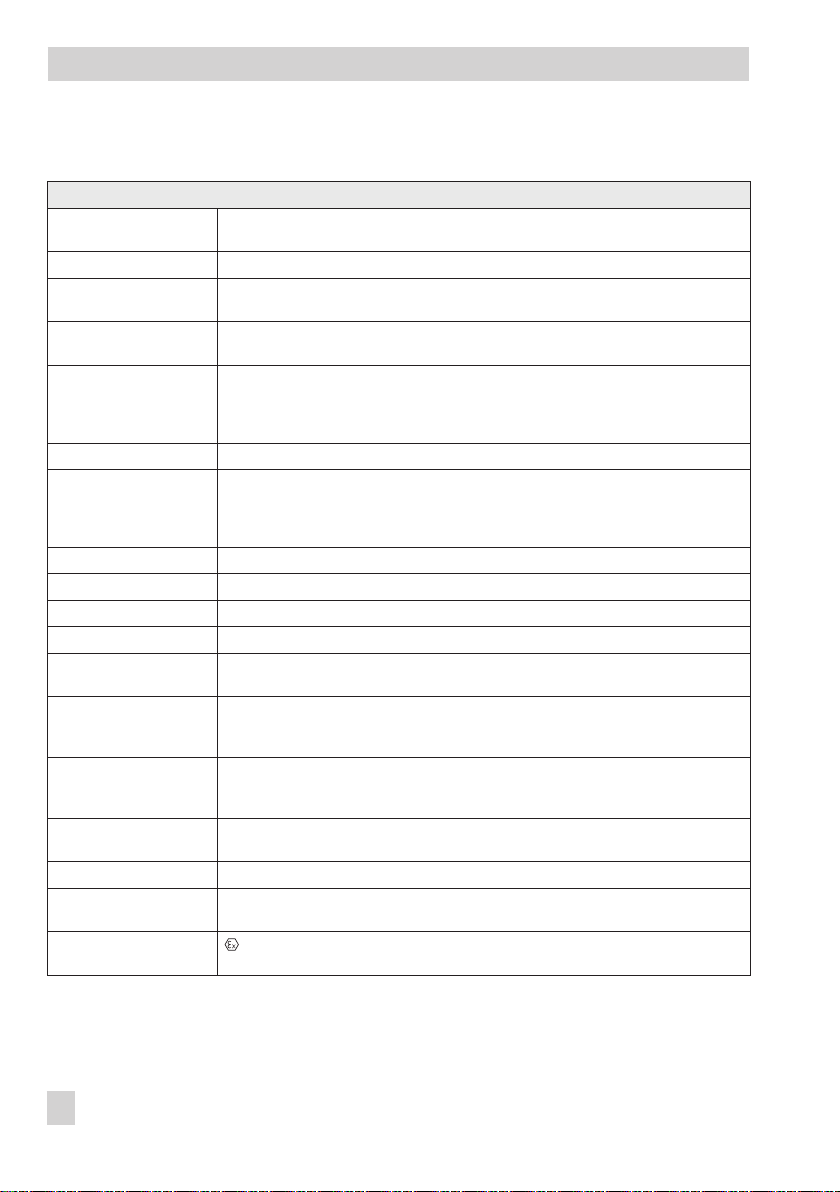

The positioner basically consists of a travel

sensor system that functions proportional to

resistance, an analog i/p module with

downstream booster as well as the electronic

unit with a microcontroller. All parts are en-

closed in an Ex d housing. The electrical

cables are connected over a separate termi-

nal compartment which also has Ex d pro-

tection.

The position of the valve is transmitted as

linear travel motion or angle of rotation to

the travel sensor (2) and to an analog PD

controller (3). Simultaneously, an A/D con-

verter (4) transmits the position of the valve

to the microcontroller (5). The PD controller

compares the actual value with the 4 to

20 mA DC control signal issued by the con-

trol unit.

In case of a system deviation, the operation

of the i/p converter (6) is changed so that

the actuator (1) is filled or vented via the

downstream air capacity booster (7). This

causes the closure member of the control

valve to move to the position determined by

the reference variable.

The pneumatic air capacity booster (7) and

the pressure regulator (8) are provided with

supply air. An intermediate flow regulator

(9) with fixed settings is used to purge the

positioner and also guarantees trouble-free

operation of the pneumatic booster. The out-

put signal pressure supplied by the booster

can be limited over the software.

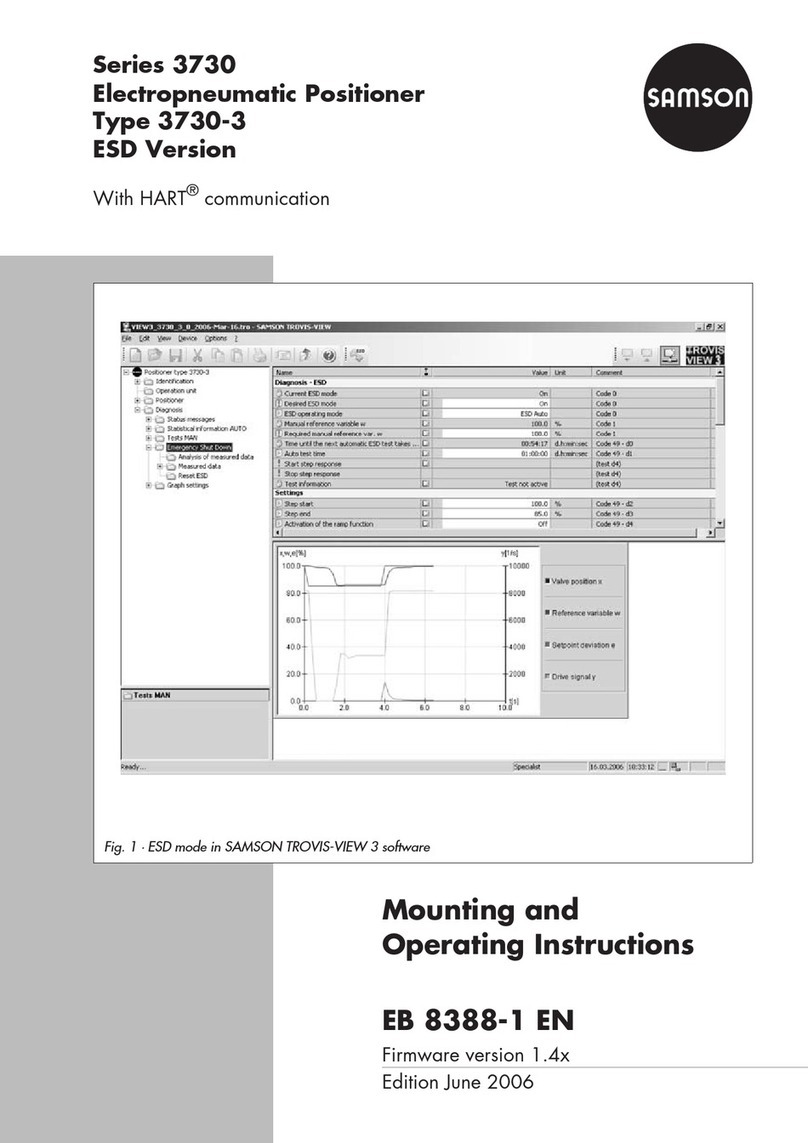

Serial interface

The positioner is equipped with an interface

to allow the SAMSON TROVIS-VIEW Con-

figuration and Operator Interface software

to transmit data and parameters over a se-

rial interface adapter from the RS-232 inter-

face of a computer to the positioner.

Options

Forced venting: If there is no operating volt-

age at the corresponding terminals, the i/p

module is not actuated. The positioner

cannot operate anymore and the control

valve moves to the fail-safe position deter-

mined by the actuator, independent of the

reference variable.

Binary contact: The positioner has three in-

ternal binary signals which can be analyzed

over the A/B/C terminals. Two of these sig-

nals are assigned to the valve end positions

6EB 8387-3 EN

Design and principle of operation