3

Rev 2, 18.06.19

Your safety and the safety of others are very important.

We have provided many important safety messages in this manual and on your appliance. Always read

and obey all safety messages.

This is the safety alert symbol.

This symbol alerts you to potential hazards that can kill or hurt you and others.

All safety messages will follow the safety alert symbol and the word

“Danger.” This word mean:

DANGER

You can be killed or seriously injured if you don’t follow

instructions.

All safety messages will tell you what the potential hazard is, tell you how to reduce the chance of injury,

and tell you what can happen if the instructions are not followed.

IMPORTANT SAFETY INSTRUCTIONS

WARNING: To reduce the risk of re, electric shock, or injury when using your Maturmeat®,

follow these basic precautions:

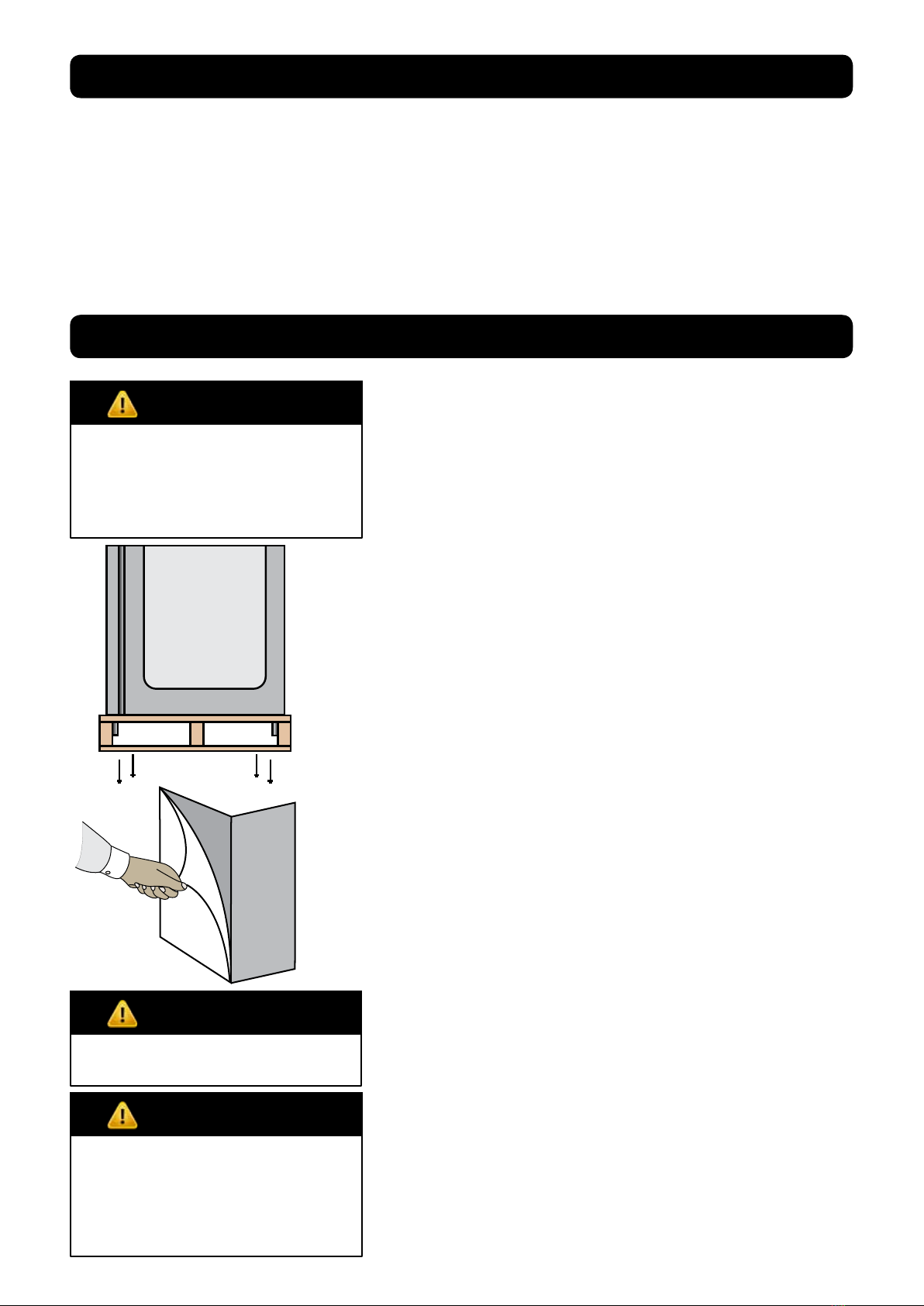

■ After unpacking, make sure the machine is

complete and free from damage. If in doubt,

do not use and contact a qualied technician.

■ Check that the information on data plate

corresponds with the main power supply.

■ This appliance must be used exclusively for

the purpose for which it was made. Any other

use is considered improper and therefore dan-

gerous.

■ The machine must be handled only by trained

personnel.

■ For any eventual repairs please contact an

authorized dealer and/or technician, use only

original replacement parts.

■ Do not wash the machine with high pressure

water jets.

■ Fumotic® avoring/humidication processes

and humidity probes are not to be used be-

low –3°C (minus three degrees centigrate),

and are excluded from operation and conse-

quently unusable and unreilable, the manu-

facture is not liable for programming differing

from the aforementioned

■ All working parameters described in bro-

chures, price lists, refer to programming and/

or functionality to achieve a single process

separately, and not connected or linked.

■ Arredo Inox Srl assumes no responsibility for

any errors that may appear in this document.

In no event shall Arredo Inox Srl be liable for

incidental or consequential damages arising

from use of this document or the software and

hardware described in this document.

■ The information contained within the user

manual is subject to change without notice

and should not be construed as a commit-

ment by Arredo Inox Srl.

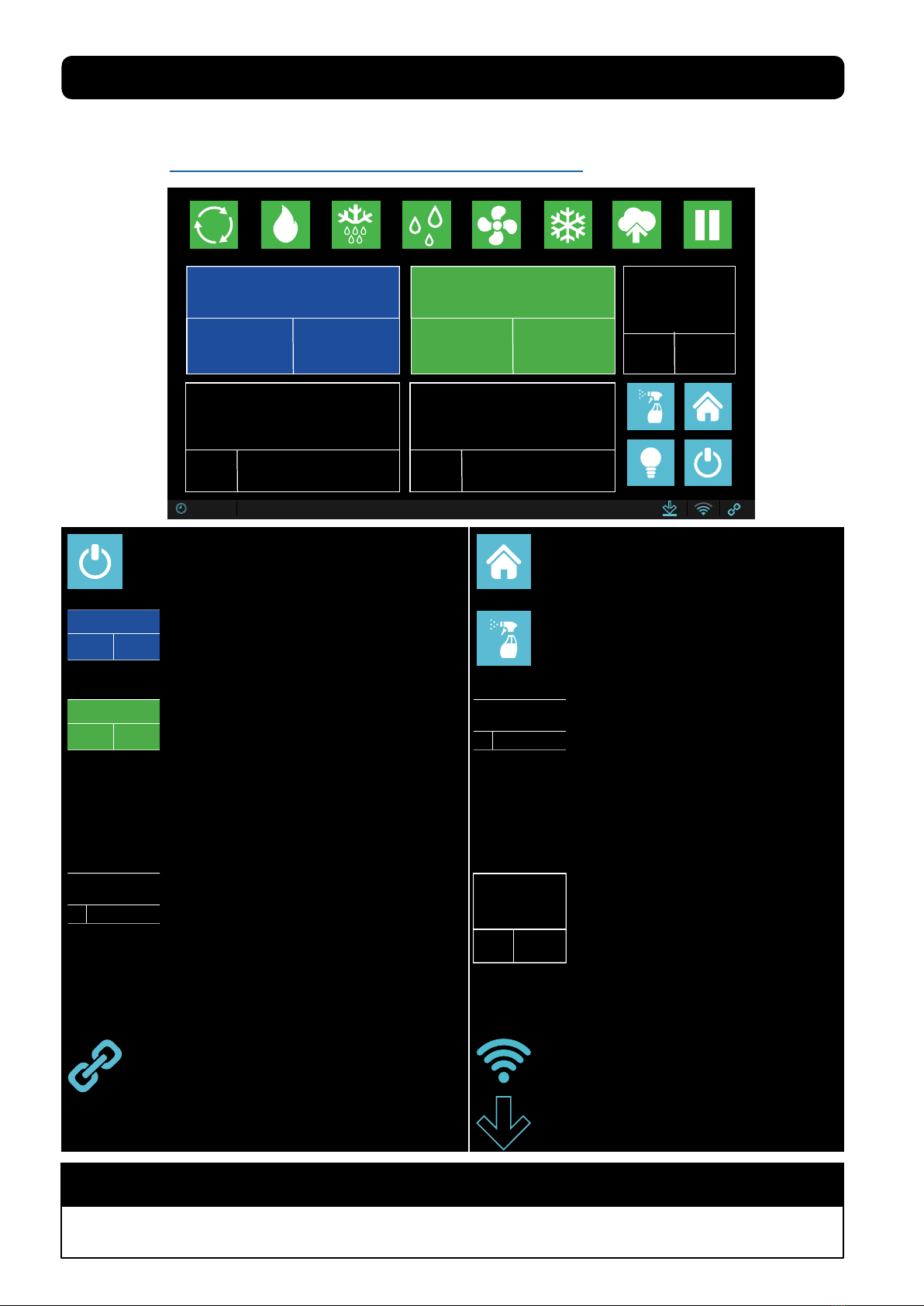

■ The default climatic recipes programmed

in your Maturmeat® are suggested and are

modiable by the user, they are meant to be

used a guide.

■ Always shut down power to the unit before

attempting any work on the unit, other than

the exclusive purpose for which it was made.

■ Do not store explosive substances such as

containers with explosive propellants in side

your Maturmeat®

■ Not respecting any of the aforementioned

points may compromise the safety of the

machine and or the user.

SAVE THESE INSTRUCTIONS

1.1 GENERAL SAFETY WARNINGS

This manual replaces all previous versions, and contains up to date information on procedures and settings, with the

exception of electrical drawings (nd production dates on each drawing)

This document and parts thereof must not be reproduced or copied without Arredo Inox Srl’s written permission, and

contents thereof must not be imparted to a third party nor be used for any unauthorized purpose. Contravention will

be prosecuted.