Construction and Design:

The ARRIFLEX 16 BL is a noiseless 16 mm mirror reflex newsreel camera with electric

drive. In order to maintain the excellent technical features of the proven ARRIFLEX

models 16 St and 16 M (such as the precision film registration pin, forwarc:l and reverse

operation, tachometer, footage indicator, interchangeable motors, mirror reflex

system, etc.), achieve a low noise level and avoid excess weight, this new camera

has been built with a fully sound-proofed construction in which all components which

produce or conduct noise have been insulated within or upon the camera body. This

applies to the camera mechanism complete with the film transport system, the inter-

changeable motors, the lens, the viewfinder system, and the magazines. This con-

struction makes the ARRIFLEX 16 BL an extremely versatile, noiseless, and relatively

light-weight newreel camera which can be used equally well whether mounted upon

a tripod or hand-held, with or without a shoulder support. Taking today's highly

advanced zoom le.nses into consideration, the ARRIFLEX 16 BL has been constructed

with only one lens mount especially designed for the use of zoom lenses although

normal lenses may also be used. The lenses can be exchanged quite easily. The

ARRIFLEX 16 BL works with quick-changing magazines with built-in feed and take-

up mechanisms. The film transport is the same as in the ARRIFLEX 16 St and 16 M,

having a precision registration pin for forward and reverse operation. The viewfinder

system is different in some respects from other ARRIFLEX 16 models, the most impor-

tant difference being the relocation of the ground glass in the forward focal plane.

The ARRIFLEX 16 BL is operated in the same manner as the ARRIFLEX 16 M, with the

exception of the following changes:

The operating controls normally firmly coupled with the camera mechanism are in-

sulated in the ARRIFLEX 16 BL to prevent noise from being conducted from the camera

interior. This applies to the lens controls for focus (1/4), focal length (1/10 a. 11),

diaphragm (11/10), inching knob (111/1), re-set for the footage indicator (111/4), and

the two knurled disks (11/14) for taking up film slack in the magazine. The three lens

controls are connected to the lens by means of rubber elements. The latter four con-

trol knobs mentioned above are cornoletely disengaged and must be pressed in to

couple them with the gears of the camera mechanism. Important Never use the inch-

ing knob (111/1) while the camera motor is running

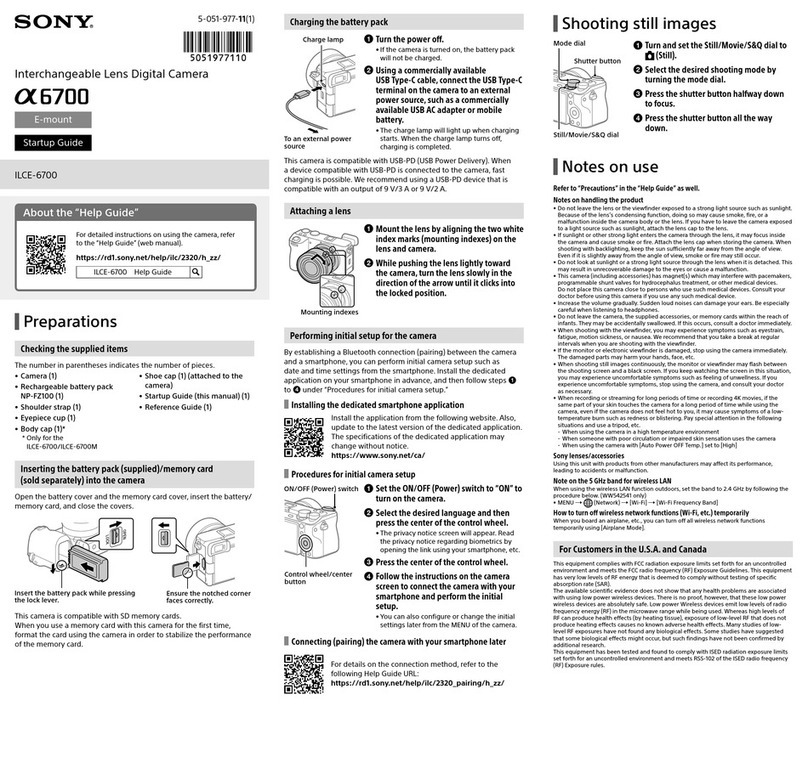

Fig- I

1 Knurled knobs for adjusting bellows

2 Matte box boom

3 Plexiglass window

4 One of three focusing grips

5 Lock: lens housing/camera

6 Magazi ne Iid lock

7 Exchangeable pilot tone and start marking unit

8 Lock to fi Iter door

9 Focus index mark

10 Special zoom lever

11 Focal length adjustment ring

12 Push button to unlock lens

13 Short periscopic viewfinder

14 Collar for mounting eyepiece

15 Knuried ring for locking diopter adjustment

16 Diopter adjustment ring

17 Rubber eyecup

18 Lock to periscopic viewfinder

19 Camera door lock

Fig_ II

1 Magazine lock

2 Accessory shoe

3 Release

4 Hand grip

5 Matte box boom

6 Effects mask mounting

7 Matte box bellows

8 Hinge to filter door

9 Filter holder

10 Diaphragm adjustment grips

11 Camera motor cap

12

Zero·

re-set for footage counter

13 Fi 1m p lane mark

14 Knurled disks for tightening film slack

15 Film supply indicator

- 1 -

/