5

Trouble Shooting Matrix (cont.)

Maintenance Schedule

Problem Possible Cause Solution

SLUGGISH PERFORMANCE

(continued)

Slipper clutch adjustment too loose Check slipper is set to factory setting or your

prefered setting - see page 7 or model manual

Initial acceleration mode or reverse speed

on MEGA waterproof ESC set too low

Modify MEGA waterproof ESC settings

MEGA electric motor dirty or damaged Clean, check condition and/or replace - visit

ARRMA-RC.com for more information

Drivetrain dirty or damaged Clean, check condition and/or replace - visit

ARRMA-RC.com for more information

FRONT WHEELS LIFT WHEN

ACCELERATING

Slipper clutch adjustment too tight Check slipper is set to factory setting - see

page 7 or model manual

NO CONTROL OF VEHICLE

OR SHORT RANGE

ARRMA ATX transmitter batteries are

weak or fitted incorrectly

Check transmitter batteries and refit - see

model/transmitter manual

Servo and ESC signal wires to ARX

receiver loose or connected incorrectly

Reinstall signal wires to receiver

ARRMA transmitter and receiver are not

'bound' correctly

Transmitter and receiver need to be bound -

see model/transmitter manual

STEERING/THROTTLE

OPERATION INTERMITTENT

ESC has shut down due to overheating Stop driving and allow ESC or motor to cool

down

ARRMA transmitter and receiver are not

bound fully or are suffering interference

Check for sources of interference and re-bind

transmitter/receiver - see transmitter manual

VEHICLE WANDERS LEFT/

RIGHT WITHOUT STEERING

INPUT

ARRMA ATX Steering trim setting out Adjust steering trim - see model/transmitter

manual

Damaged steering components C h e c k co m p o n e n t s a n d r e p l a c e - v i s i t

ARRMA-RC.com for advice

Drivetrain dirty or damaged Clean, check condition and/or replace - visit

ARRMA-RC.com for more information

STEERING OR THROTTLE

FUNCTION REVERSED

Relevant channel of ARRMA ATX

transmitter is reversed

Reverse relevant channel on ARRMA ATX

transmitter - see model/transmitter manual

Check that the wires from the ESC to the

motor are connected correctly

Reconnect in the correct orientation (orange

to red and blue to black) ensuring fit is tight; if

not pinch female connector with pliers

LIMITED STEERING ANGLE ARRMA ATX transmitter steering dual-

rate set incorrectly

Adjust ARRMA ATX transmitter dual-rate -

see transmitter manual

Damaged steering components C h e c k co m p o n e n t s a n d r e p l a c e - v i s i t

ARRMA-RC.com for advice

MEGA waterproof ESC is damaged Replace with new unit - visit ARRMA-RC.com

for advice and upgrades!

Maintenance

This chart is just a guide. Running in dusty, sandy or wet conditions will mean

certain maintenance tasks will need to be performed more frequently. Check for wear or damage after every run. Do not

wait until the recommended time for maintenance if parts appear badly worn or need renewing.

Maintenance Task Page Runs

Chassis Maintenance 6

Wheel and Tyre Maintenance 6

Slipper clutch Adjustment 7

Spur/Pinion Mesh Adjustment 7

Slipper Pad Replacement 8

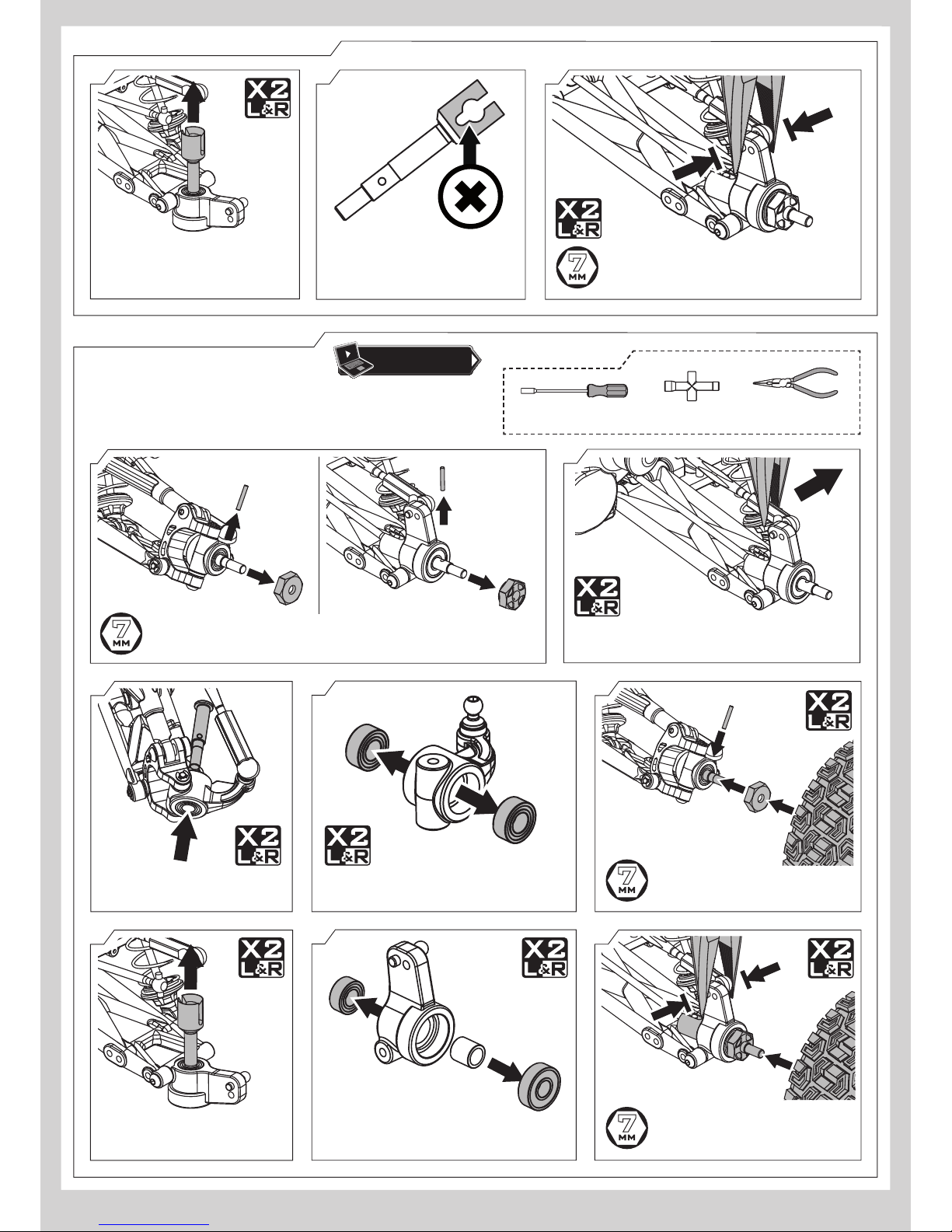

Driveshaft Maintenance 9

Rear Axle Maintenance 9

Wheel Bearing Replacement 10

Shock Oil Replacement 14

Differential Oil Replacement 16