Arrow Emergency Systems | 17 Bailey Court Brendale Q 4500 | P: (07) 3881 3302 | www.arrowes.com.au Page | 3

Contents

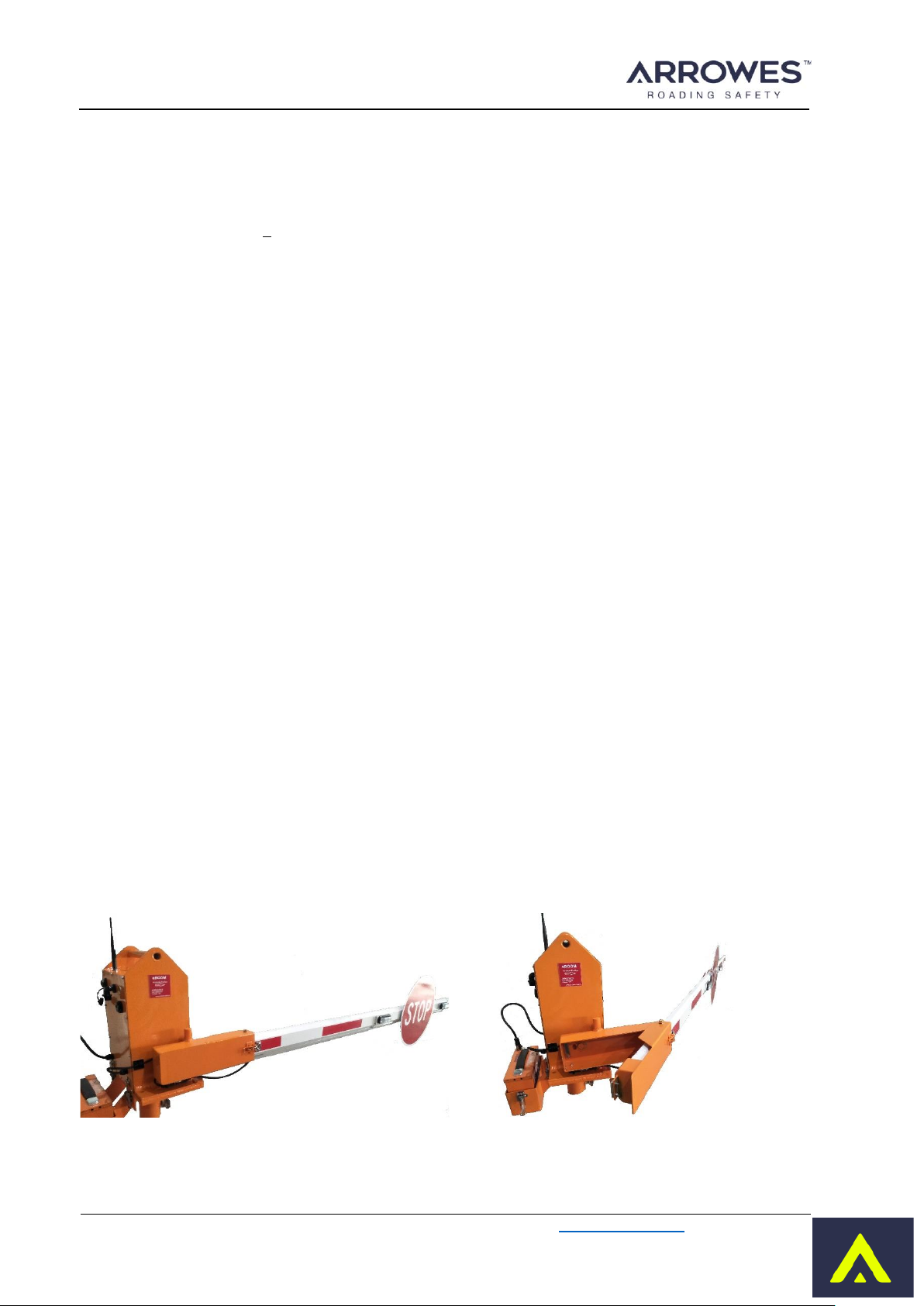

eBOOM™ System Components Diagram............................................................................................................4

Equipment Parts.................................................................................................................................................5

Accessories .....................................................................................................................................................5

Safety Considerations.........................................................................................................................................6

eBOOM™SystemSpecifications........................................................................................................................7

Obstacle sensor specifications ...........................................................................................................................9

Labels..................................................................................................................................................................9

Key Features.....................................................................................................................................................10

Safety Features.................................................................................................................................................10

Unit Assembly/On-site Setup............................................................................................................................11

Operational Procedures....................................................................................................................................13

eBOOM™ Unit...............................................................................................................................................13

Hand Remote Controller –HRC....................................................................................................................14

LED indicators...........................................................................................................................................14

Modes of Operations................................................................................................................................15

Operational Steps.....................................................................................................................................15

Pairing the Handheld Remote Controller (HRC) to eBOOM™units .................................................................16

Un-pairing.....................................................................................................................................................16

Pairing HRC Unit1 (Left side of the HRC) .....................................................................................................16

Pairing HRC Unit2 (right side of the HRC)....................................................................................................17

Batteries - Care, Safe Handling and Charging...................................................................................................18

Maintenance.....................................................................................................................................................20

Calibration ........................................................................................................................................................20

Troubleshooting ...............................................................................................................................................21

Repairs & Servicing...........................................................................................................................................22

Safe Transportation ..........................................................................................................................................22

Material Life......................................................................................................................................................22

Warranty...........................................................................................................................................................22

eBOOM™ Operations & Service Manual