3

Declaration of performance

F-12/2016CE_DoP_Rf-t_V14_EN

DECLARATION OF PERFORMANCE

Declarationofperformance

CE_DoP_Rf-t_V14_EN

F-12/2016

1. Unique identication code of the product-type: KAMOUFLAGE P

2. Intended use/es: Smoke evacuation shutter to be used in smoke control systems, in multi-compartment applications at re temperatures, or in single-compartment applications.

3. Manufacturer: Rf-Technologies NV, Lange Ambachtstraat 40, B-9860 Oosterzele

4. System/s of AVCP: System 1

5. Harmonised standard / European Assessment Document; notied body / European

Technical Assessment, Technical Assessment Body, notied body; certicate of

constancy of performance:

EN 12101-8:2011, Efectis with identication number 1812; 1812_CPR_1043

6. Declared performance according to EN 12101-8:2011 (re resistance according to EN 1366-10, classication according to EN 13501-4)

Essential characteristics Performance

Range Product Wall type Wall Installation Classication

350x385 mm ≤ Kamouage

P 1V ≤ 700x775 mm;

550x1075 mm

Kamouage 60 P Shaft Promatect L500 ≥ 30mm 1 EI 60 (hod i no) S 1500 AA multi

Geoam ≥ 30mm 1 EI 60 (hod i no) S 1500 AA multi

Geotec ≥ 30mm 1 EI 60 (hod i no) S 1500 AA multi

Tecniver ≥ 35mm 1 EI 60 (hod i no) S 1500 AA multi

Glasroc F V500 ≥ 35mm 1 EI 60 (hod i no) S 1500 AA multi

Kamouage 120 P Shaft Promatect L500 ≥ 50mm 1 EI 120 (hod i no) S 1500 AA multi

Geoam ≥ 45mm 1 EI 120 (hod i no) S 1500 AA multi

Geoam Light ≥ 35mm 1 EI 120 (hod i no) S 1500 AA multi

Geotec ≥ 45mm 1 EI 120 (hod i no) S 1500 AA multi

Tecniver ≥ 50mm 1 EI 120 (hod i no) S 1500 AA multi

Glasroc F V500 ≥ 50mm 1 EI 120 (hod i no) S 1500 AA multi

Desenre HD ≥ 35mm 1 EI 120 (hod i no) S 1500 AA multi

Desenre ≥ 45mm 1 EI 120 (hod i no) S 1500 AA multi

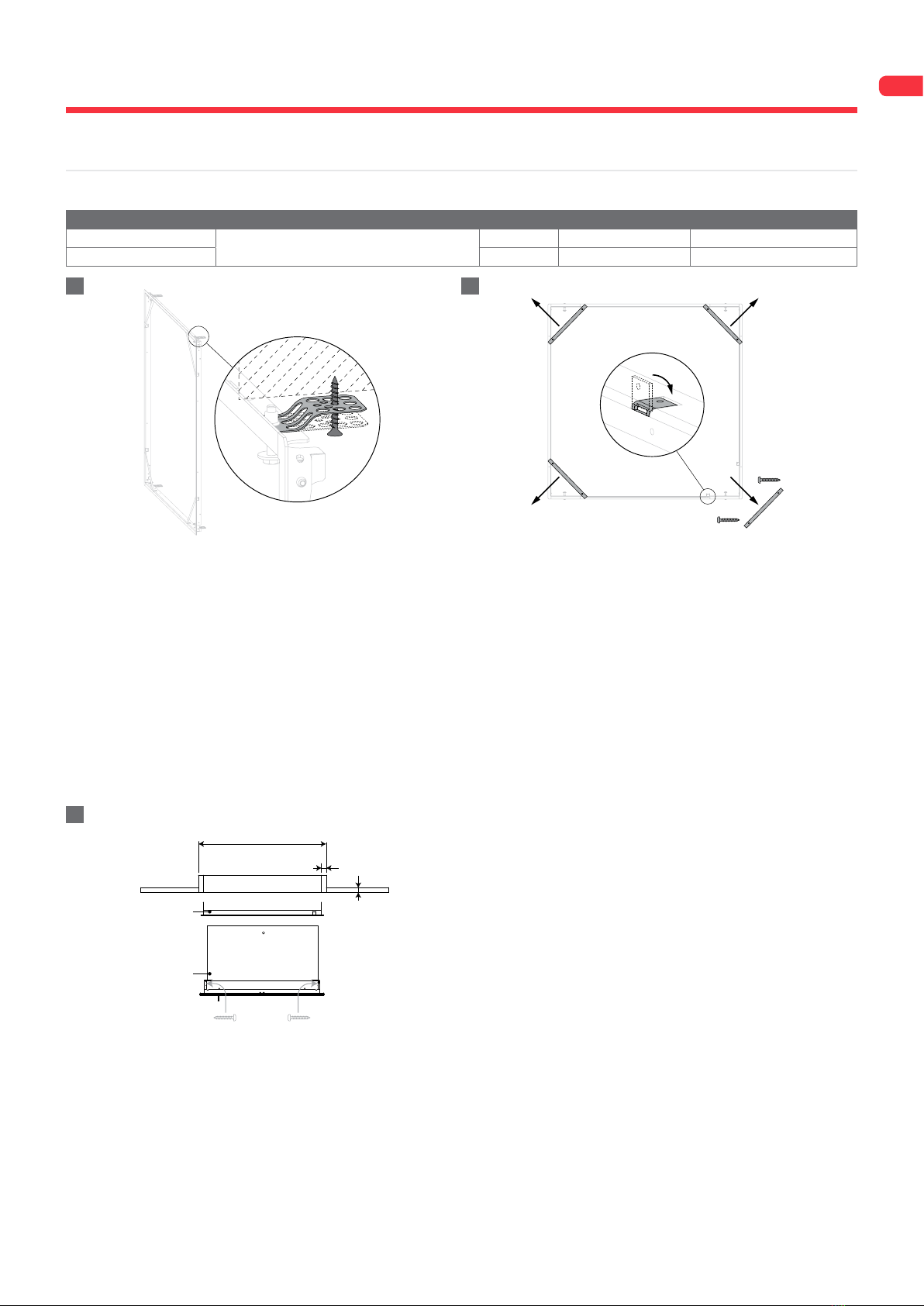

1 Type of installation: shaft-mounted 0/90°/180°/270°

Nominal activation conditions/sensitivity: Pass - automatic activation

Response delay (response time): closure time Pass - automatic activation

Operational reliability: cycling 300 cycles (no load)

Durability of response delay: Pass

Durability of operational reliability: Pass

Approved accessories

Acrylic paint on the leaf and synthetic paint

on the frame on the side not exposed to re;

Glued wall paper on the side not exposed to

re; ATOUT RAL 9010; KAP mounting frame

High operational temperature (HOT 400/30): NPD (no performance determined)

Harmonised standard

EN 12101-8:2011

The performance of the product identied above is in conformity with the set of declared performance/s.This declaration of

performance is issued, in accordance with Regulation (EU) No 305/2011, under the sole responsibility of the manufacturer identi-

ed above.

Signed for and on behalf of the manufacturer by:

Frank Verlinden, Product Manager

Oosterzele, 12/2016