Air Compressor Controller Unit

AR100 USER’S MANUAL

All rights reserved. The content may be changed without prior notice. Rev. 00

Page 6 of 10

3. Operation

3.1. Compressor start-up

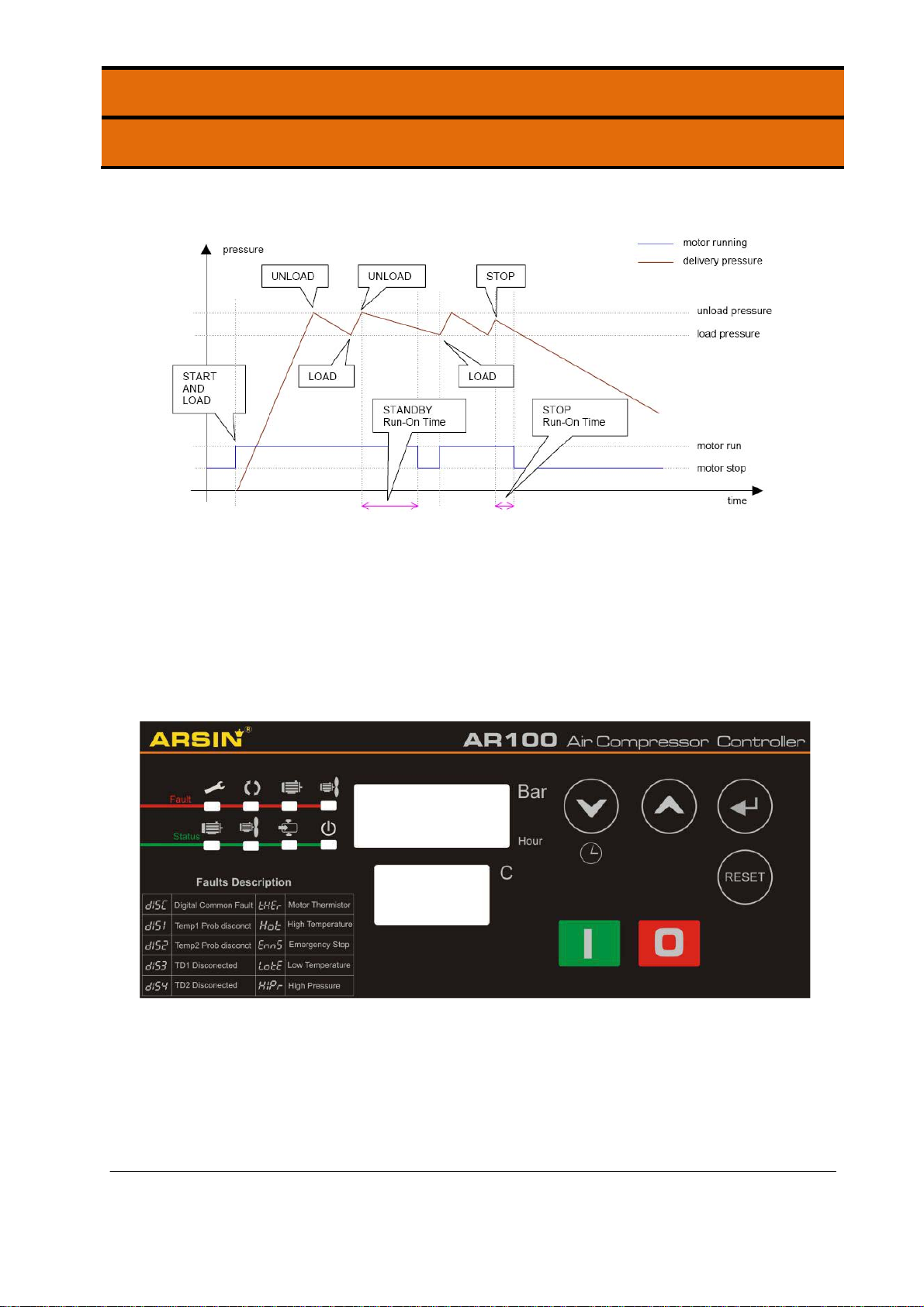

In normal operation, the detected delivery pressure controls regulation of the

compressor once the compressor has been started by pushing the start button, or by a

remote start command if enabled. The controller will perform safety checks and start the

compressor if no inhibiting conditions are detected.

If a start inhibiting condition exists the compressor will not enter the started condition

and a start inhibit message is displayed. If a run inhibiting condition exists the

compressor will enter the started condition but a main motor start is inhibited; the

compressor will remain in the standby condition and a run inhibit message is displayed.

If a load request is present, in accordance with internal pressure settings or by remote

command, the main motor is started in a star/delta sequence. When running in delta

configuration, after the star/delta time (adjustable) has expired, the load delay time

(adjustable) prevents loading for a period to allow motor speed to stabilize. The load

delay time can be set to one second if required. When the load delay time has expired

the load valve output is energized and the compressor will load. If the unload pressure

setting is reached, or a remote unload command is received, the load valve output is de-

energized and the compressor will run offload for the standby run on time (adjustable)

before the main motor stops and the compressor enters Standby mode. The compressor

will load again if pressure falls below the load setting before the standby run on time

expires. If in Standby mode, a motor start sequence followed by the load delay time is

executed before loading.

In the event of a motor stop, initiated by a stop command or when entering standby

mode, a blow down timer (adjustable) is started. If a start request is made during the

blow down time the compressor will enter standby mode until the blow down time

expires. If already in standby mode and a load request is present, the compressor will

remain in standby mode until the blow down time has expired. For units with internal

pressure detection enabled, a minimum internal re-start pressure can also be set to

prevent a motor start sequence before internal pressure is vented. In the event internal

pressure fails to fall below the set minimum re-start pressure within two minutes after the

set blow down time has expired, a blow down fault is generated and the compressor will

shutdown. After an unload event a re-load timer (adjustable) is initiated that will prevent

reloading, this time can be adjusted to a minimum of one second if required. Normal

automated operation is ended by pushing the stop button, a remote stop command or in

the event of a shutdown fault.

When stopped manually, or by a remote command, the load value is de-energized and

the main motor allowed to run-on for the stop run on time (adjustable). This time can be

adjusted to a minimum of one second if required. Safety checks are made continuously,

if there is a condition detected that presents a hazardous or damaging situation an

immediate stop is performed and the reason displayed as a shutdown error message. If

a warning condition is detected an Alarm message is displayed and normal operation

continues.