4

1) Special advantages

AR1710 is a stable electronic control unit for screw air compressor which can provide users with running

log for integral control and management of the equipments. It adopts the method of digital process by high

efficiency RISC type microprocessor and occupies enough installation space and stability by unifying

module and control module. It provides convenience to let users know a status of operation at once

through display.

1-1) Noise solution

It is inevitable to figure for noise as an industrial controller. The digital input and output signal of AR1710 is

isolated, so it can not be allowed to flow external signal into the main board inside.CPU on main board

mounts HARDWARE WATCHDOG TIMER which can automatically recover from CPU down occurred by noise

per 32 msec., and BROWN-OUT function embedded in CPU inside supervises control power in real-time.

1-2) RISC TYPE MICOM

An assembler instruction in CPU can perform 7.3728Mbps, and logic for controlling written in CPU inside

needs about 1[m sec] based on 1 cycle. In this regard, sampling rate is about 10 times faster than the

existing controllers, so it has less probability of malfunction and more precise control.

1-3) Black Boxes: A recorder of operation status

It is possible for AR1710 to store maximum until 30 events of running log, so it is easy for preventative &

maintenance and Troubleshooting. Additionally, it is possible to verify the operation data at site occurs, so

it is helpful for users to know the reason of trouble and the status of equipment in real-time.

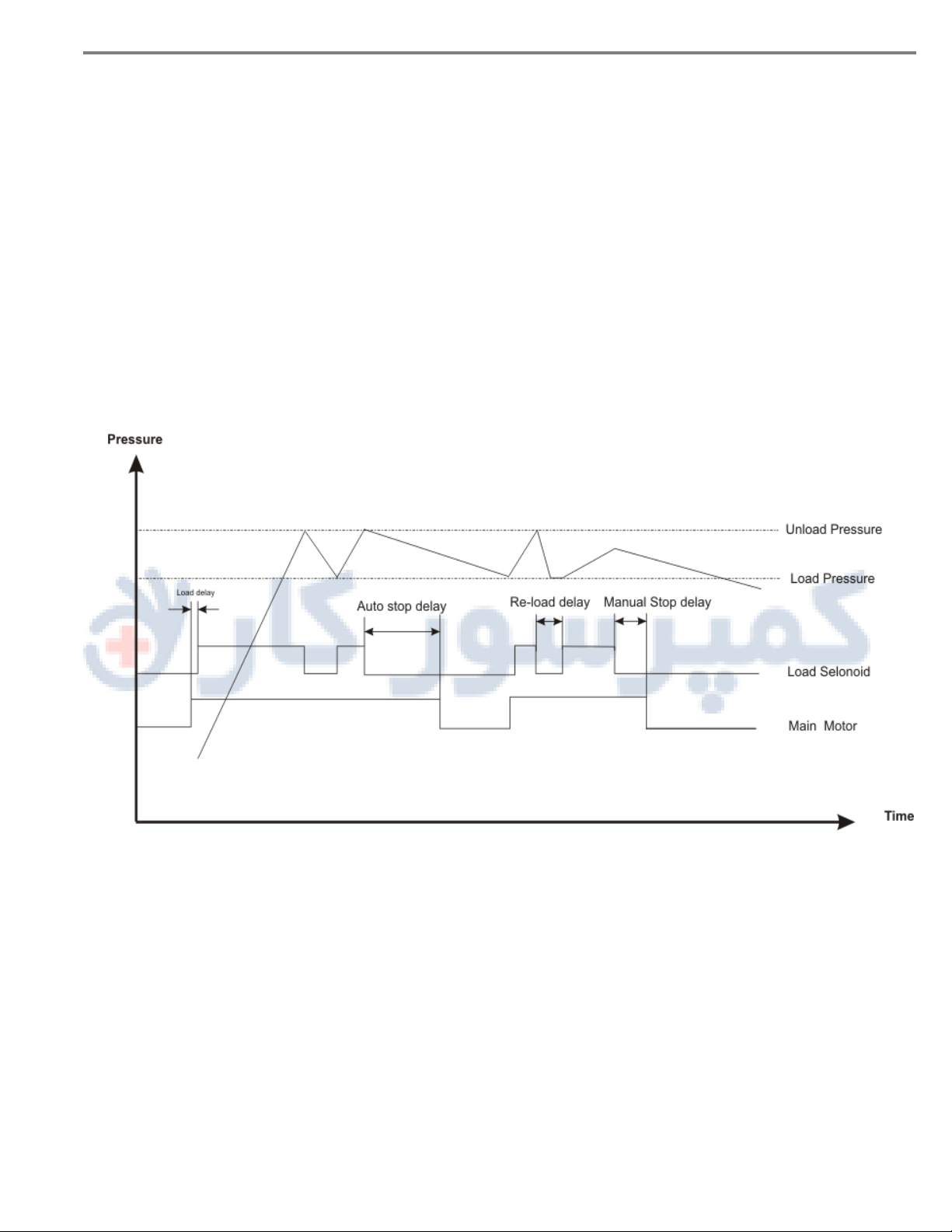

1-4) Display for operation status and/or maintenance (trip computer)

AR1710 has the display function for operation status, delay time and ready time by counting reversely, so

users can recognize the status of compressor at a glance. Also, it has the basic function to notify parts and

oil checking and exchanging schedule by calculating it automatically according to the information of

operation.

1-5) 240×128 graphic LCD (Wide Temperature Range Type: (-50 ~+150°C).Display part of AR1710 adopts

240×128 graphic LCD for user’s easy operation and recognition.

1-6) Minimization

It is possible to minimize compressor by occupying a small space due to unifying design of control part and

display part.

1-7) Scalability

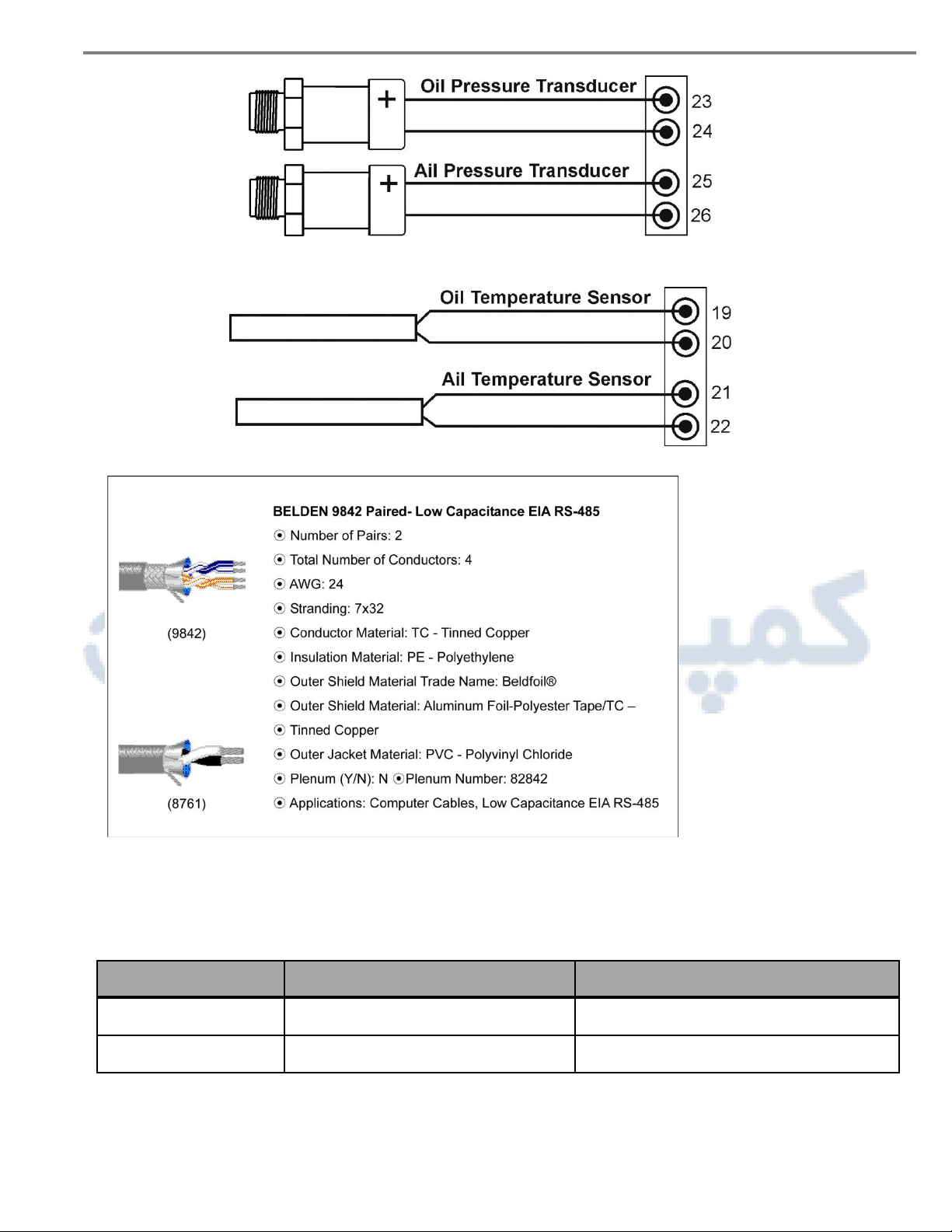

It provides users with RS485 port, MODBUS RTU standard protocol and MMI software and automatic

interface.