4

Description

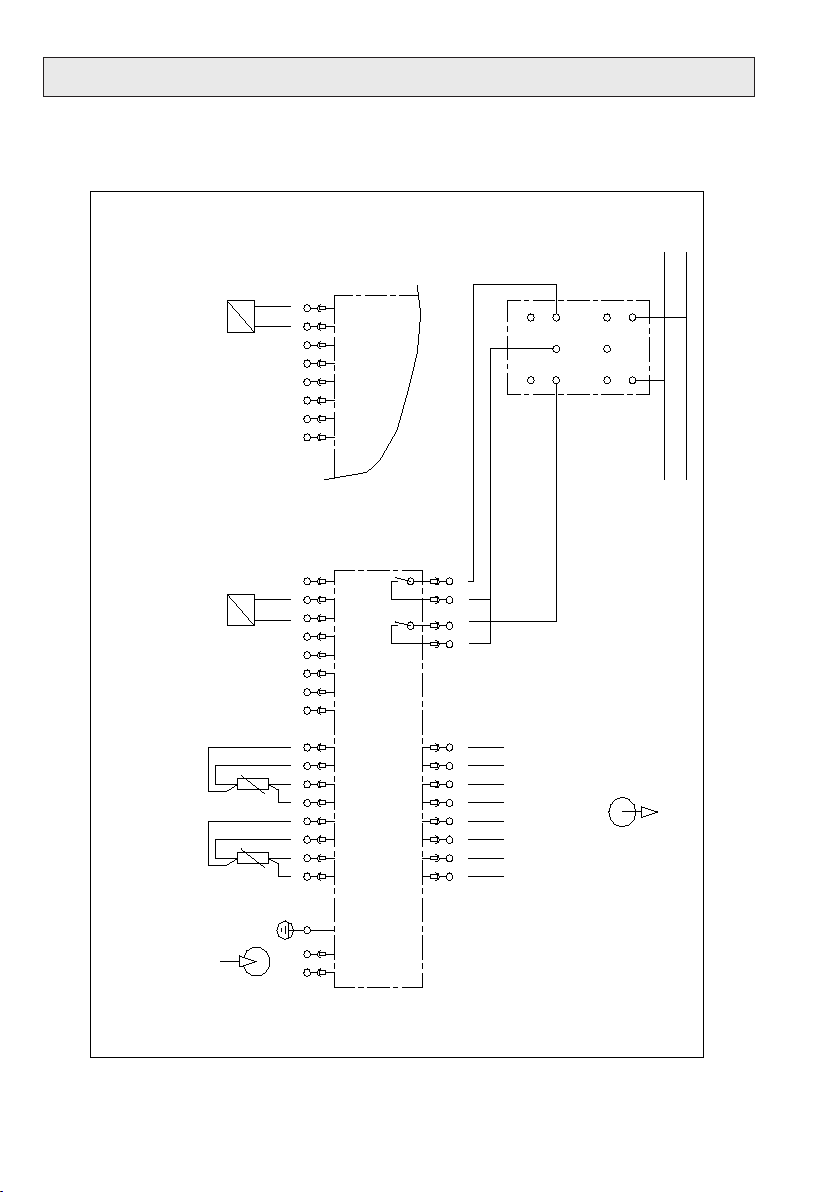

The heat meter WR 200-F is a microcontroller-controlled computing device for detecting the

heat energy in heating systems with thermal water or other uids (water-glycol mixtures or

thermal oil). The counting of the thermal energy and the amount of heat carrier is on a 4-line

alphanumeric LCD display with backlight. Through a key scan, all measured and calculated

values are shown with their physical units, date and time.

The heat meters have a built-in clock with automatic calendar up to 2099. Thus in adjustable

periods, energy counts are available via resettable counters.

The temperature of the heat meter inputs are provided for RTD Pt100 DIN 43760 in four-

wire circuit.

To the ow input, any transmitter with the signal range 0 ..20 mA or 4 ..20 mA can be con-

nected. A two-wire transmitter with the signal range 4 .. 20 mA can also be connected,

supplying the transducer is now performed directly from the heat meter.

The characteristic line of ow input can be set linear or square root.

An analog output circuit provides 4 analog signals 0 ..20 mA or 4 ..20 mA. The analog

signals supplied from the calculation circuit and galvanically separated with respect to a

common earth terminal.

For external processing of the counts pulse outputs are provided. Here as an option a M-

Bus loggers can be connected.

For the power supply the voltage 230 V 50 Hz is required. A built-in backup battery secures

the counts during a power failure.

The heat meters are housed in an aluminum prole housing for snap-rail mounting. For

installation in a control panel corresponding mounting hardware is provided. For wall mount-

ing, the heat meter can be mounted in a plastic housing with IP55 protection.