Waterloo Multilevel System Assembly Manual

Page 4

3.0 Preparation

The number and specific order in which each component of the System are to

be assembled must be determined ahead of time. The depths of the desired

monitoring zones and layers of backfill (where applicable) must be determined in

advance of the installation. The design log will serve as a reference during the

install. Ensure that an ‘as built’ installation log is maintained. See Appendix I for

an example of a “Waterloo System Installation Log”.

Before the install date, reconfirm that the borehole is still open to its target

depth. Once the Waterloo System is received, make sure that the shipment

looks complete and that nothing appears damaged. Contact Solinst immediately

to resolve any issues before proceeding with the install.

If a Solinst Trainer is requested, the training will be completed in its entirety,

prior to starting the installation. See Appendix IV for the Terms and Conditions

of training.

The System weighs about 1 lbs/ft., which doesn’t include the weight of the

Packers. Therefore, at least two physically strong field assistants will be needed

to lower the System by hand. If the depth to water is more than 100 ft. (30 m)

below ground surface, then a hoisting winch (drilling rig) will be needed to assist

with holding and lowering the System via an optional support cable.

Tools and equipment you should bring for the installation:

• Appropriate safety precautions and equipment to ensure a safe

working environment at your site

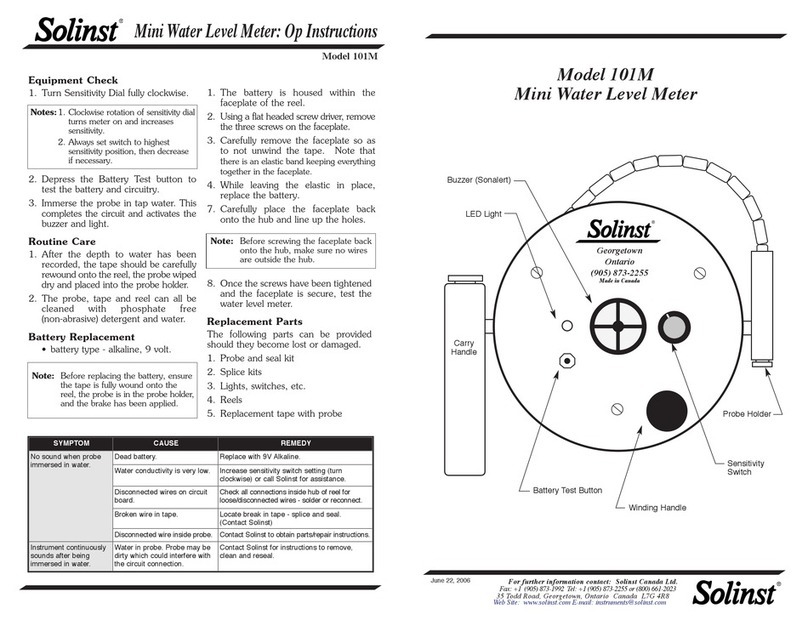

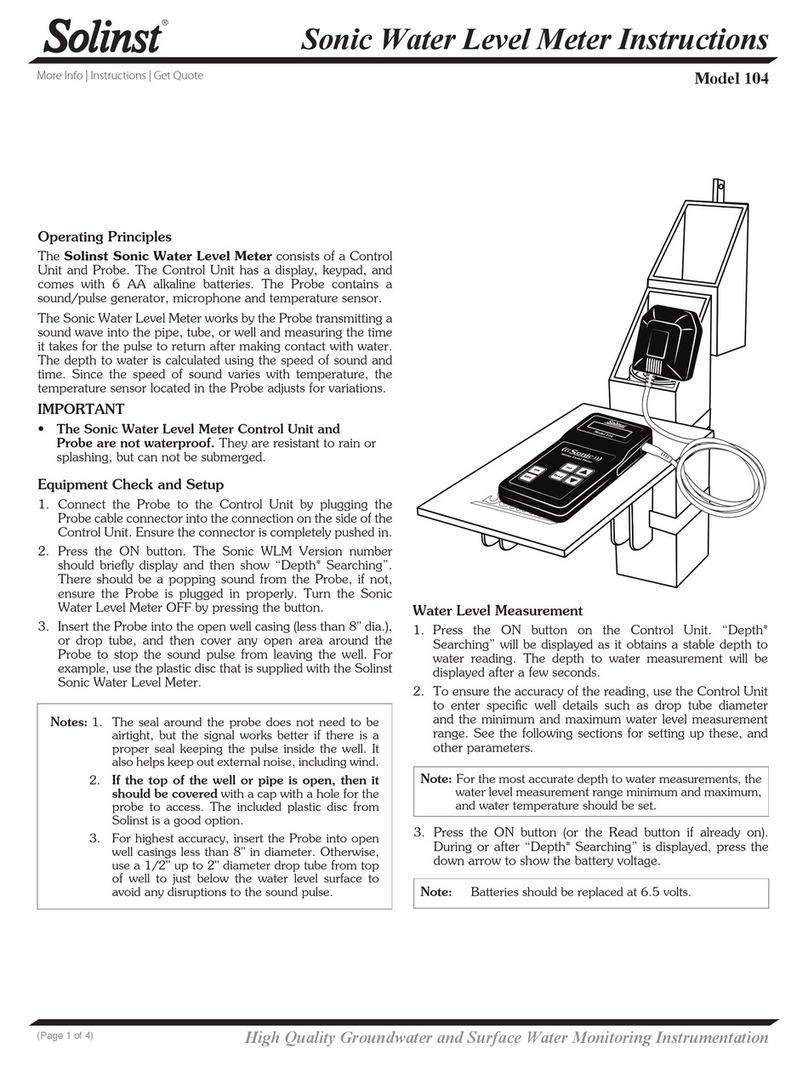

• Water Level Meter/Well Depth Indicator

• Lights and/or security if the installation goes beyond daylight hours or

more than 1 day is needed to complete the installation

• Plastic sheeting to keep the Waterloo casing, tubing, etc. clean when

being laid out on the ground during installation

• Pylons or traffic cones for safety and to identify the lay down area or

work zone

• Hand-spray water bottle used to lubricate pipe joints

• Two 5 gal pails

• One roll of black electrical tape to temporarily identify the ports and

associated pump tube discharge ends

• 11/16" (18 mm) and 5/8" (16 mm) wrenches

• Hacksaw - to achieve desired System stick-up

• Large dowel or spindle

• Small piece of sand paper to assist in pushing tubing over the pump

stems

NOTE

In designing the layout, it is

preferable to allow one to two feet

of clearance above the bottom

of the borehole. Problems of

measurement inaccuracy, sloughing

during installation, and other

unforeseen events which may

prevent well completion are thus

minimized.

NOTE

If the depth to water is greater than

100 ft. (30 m) below ground surface,

lower the system with the support

cable and drilling rig.

NOTE

Be sure to document the position

and placement of each downhole

component, during the installation.

An ‘as built’installation log is a

crucial part of knowing where each

monitoring zone is placed.