EVO Additive Manufacturing Center User Manual

airwolf3d.com/evo-owners/evo-user-guide/

Before You Begin

Letter From The Manufacturer

Thank you for choosing Airwolf 3D and the EVO Additive Manufacturing Center. We pride

ourselves on providing excellent-quality machinery and an overall outstanding user

experience. Like you, we are engineers, makers, designers, artists, and educators.

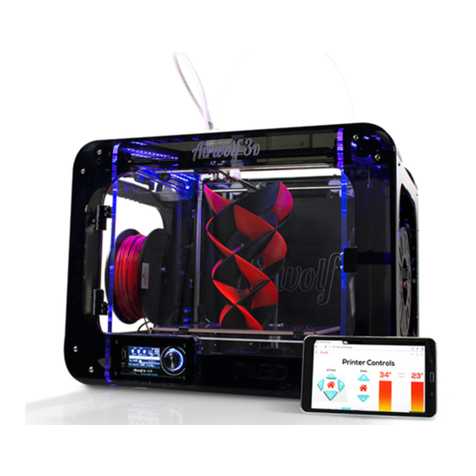

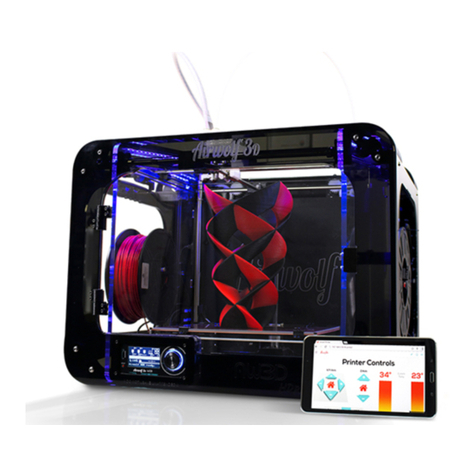

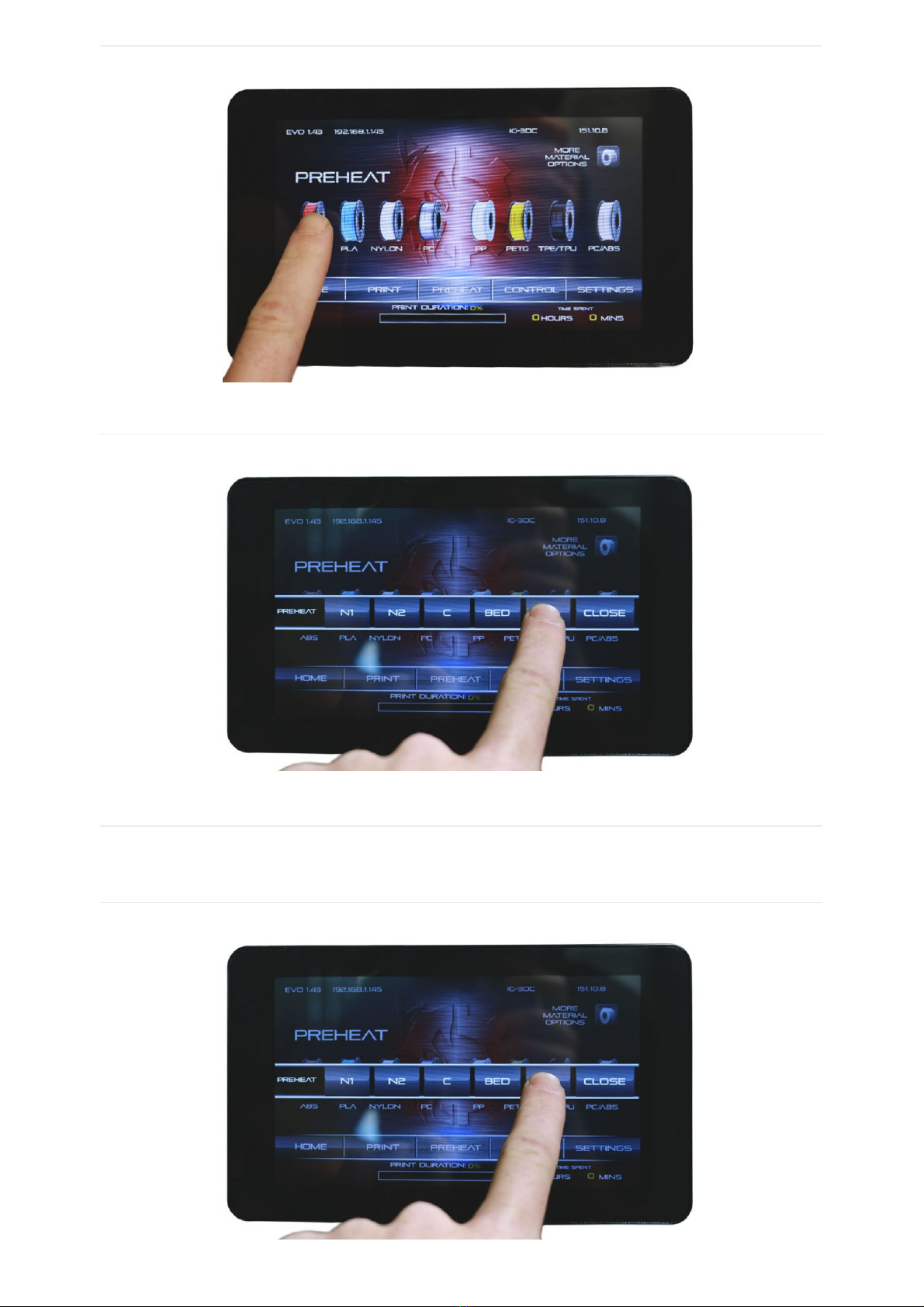

EVO is the most advanced desktop 3D printer in the industry with features such as 40-plus

material capability, enclosure heaters, large 12x12x11 build envelope, advanced touch

screen interface, and our own Genesis microcontroller designed especially for the EVO.

We have taken our customers’ feedback on the 5.5, XL, HD, and AXIOM series printer and

incorporated it into the EVO, attempting to push 3D manufacturing to the next level. You

will not find another machine like the EVO for the desktop.

At Airwolf 3D we do not see you as just another customer. You are family. You are a

member of an elite group who have decided to add a high performance machine to their

tools. We have created this guide to get you started with the best experience possible, and

give you the instructions needed to push the boundaries of additive manufacturing. Now go

create, inspire, design, and push the limits — welcome to the WOLFPACK!

Register Your Machine

Register your machine to take full advantage of the EVO Owners Program. Benefits

include:

White Glove Service from a dedicated team

Notifications of important firmware updates

Prioritized feature requests

Early access to hardware upgrades and beta products

Registration is quick, easy, and ensures the best experience possible: Register for EVO

Owners Program.

Safety Guidelines

PLEASE READ CAREFULLY BEFORE PRINTER OPERATION

EVO is an advanced machine capable of reaching extremely high temperatures and fast

speeds.

Please be aware of possible hazards when operating.

BURN HAZARD