PC Interface Electronics PD-ISA16V3 Technical Documentation V3.21_E

tec5 AG Page I 8 / 27

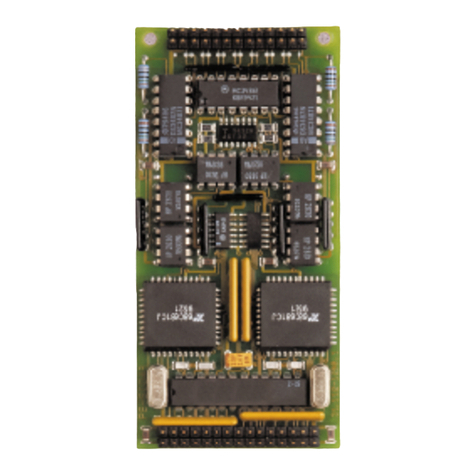

I.3.4 FIFO Buffer Memory

The buffer memory consists of two word length cascaded, asynchronous FIFO memory chips (type

SN74ACT720x, x designates the storage capacity of the component [2:1K*9 / 3:2K*9 / 4:4K*9 /

5:8K*9] or type IDT720x, x designates the storage capacity of the component [3:2K*9 / 4:4K*9 /

5:8K*9 / 6:16K*9]).

The PC/AT Interface Electronics PD-ISA16V3 in standard version is equipped with 2 chips type

SN74ACT7203 or IDT7203 (organization 2 KByte * 9, IC7 and IC8) in plug-in sockets. For larger

memory capacity, the 2 kByte - IC's may be replaced by equivalent types, which are compatible in pin

assignment and functionality, offering larger memory sizes (currently available for up to 16 kBytes).

The three status signals 'Full#', 'Half#' and 'Empty#' as well as bits 2**8 of the LSB and the MSB -

FIFO have been routed to the status port. The status 'Full', 'Half' or 'Empty' is only derived from the

flags of the LSB - FIFO. Memory chips of the type SN74ACT720x do not provide a 'Half' flag.

I.3.5 PDA Readout Clock Control Unit

The GAL IC's 'tim_5x' and 'tim_6x' constitute the photo diode array (PDA) readout clock control unit.

Important input signals of this unit are:

o STSCAN2# initiates a readout scan or readout cycle of the PDA.

The mode of operation of the timer (Software, TimerSingle, Timer

Continuous) is determined by the scan cycle clocking.

The trigger mode of operation selects internal or external trigger.

The readout clock control unit generates one or several START_F#

- pulses for the Frontend, depending on the timer mode of operation.

o EOS_F# is the return signal from the Frontend Electronics. It terminates the

current scan (each START_F# - pulse is followed-up by an

EOS_F# - pulse).

o STORE-E1# in the timer mode of operation "software", Store Enable 1determines

whether the values obtained by the next scan shall be stored in the

FIFO memory. In both remaining timer modes of operation, the scan

cycle clocking automatically controls FIFO operation.

Store disabled: reset procedure for the PDA,

charges are dumped, if present.

Store enabled: read-out procedure

o BUSY_F ADC on the FEE converting (from FEE, some 64 kHz)

o CLK_F FEE clock (some 1 MHz)

In the course of one Scan, the PDA readout clock control unit generates the following control signals:

o SCANRUN status signal Scan Running indicates, that a read-out process is

performed currently (active from Start-Scan to End-of-Scan).

o BYTE_F control signal Byte-Select for ADC on the FEE:

High: ADC on the FEE writes the high-Byte (D8..D15) of the last

conversion result to ADC_D0 through ADC_D7

Low: ADC on the FEE writes the low-Byte (D0..D7) of the last

conversion result to ADC_D0 through ADC_D7

o WCLK-LB write clock for buffer memory, writes the LSB to the FIFO

o WCLK-HB write clock for buffer memory, writes the MSB to the FIFO

o 1PIXEL#1 status signal, indicates the time slot for sampling the signal from the

first photodiode in a scan by a logic low level