12/11/2017 ii WIENER_475mini.v1.0

Table of contents:

1 General Information............................................................................................................................. 3

1.1 475 Mini Crate Series Features .................................................................................................... 3

1.2 Front and Rear Side View ............................................................................................................ 4

1.3 Cooling......................................................................................................................................... 5

1.4 Power Supply ............................................................................................................................... 5

1.5 Display and CML00 Shelf Manager............................................................................................. 5

1.5.1 CML DC ON/OFF Switch and Status LED ......................................................................... 6

1.5.2 Ethernet Connector............................................................................................................... 6

1.5.3 USB Connector..................................................................................................................... 7

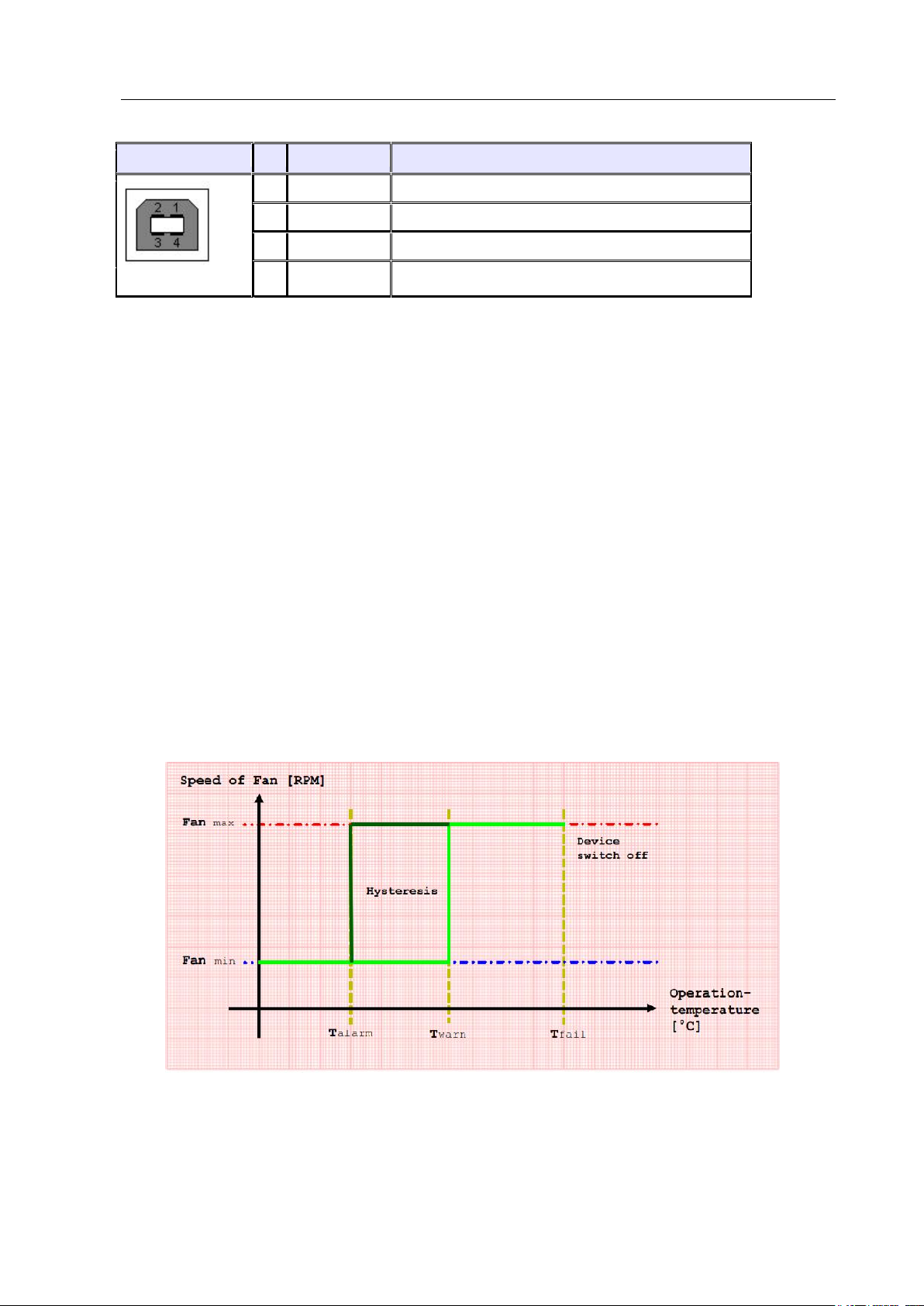

1.5.4 CML Temperature Sensor Inputs / Fan Control................................................................... 7

1.6 Ordering Information ................................................................................................................... 9

2 WIENER 475 Mini Chassis Operation............................................................................................... 10

2.1 Main operation modes and associated submenus....................................................................... 11

2.2 Front Panel LED’s...................................................................................................................... 13

3 Ethernet Remote Monitoring and Control.......................................................................................... 14

3.1 SNMP communication protocol................................................................................................. 14

3.2 SNMP Control Examples........................................................................................................... 20

3.3 Setting of IP Addresses via SNMP............................................................................................. 21

3.4 Change of Community Names / Setting of Passwords............................................................... 21

3.5 SNMP Version 3 20

3.6 WIENER SYScontrol Software ................................................................................................ 22

3.6.1 Installation SYScontrol ...................................................................................................... 28

3.6.2 Setting Preferences / IP Address and Crate Scan............................................................... 28

3.6.3 The SYScontrol Main Window.......................................................................................... 29

3.6.4 SYScontrol - Outputs ......................................................................................................... 30

3.6.5 SYScontrol –Fans.............................................................................................................. 31

3.6.6 SYScontrol –Temperature Sensors.................................................................................... 32

3.6.7 SYScontrol Networks tab................................................................................................... 32

3.7 MIB Browser.............................................................................................................................. 33

4 Technical Details VME / VME64x / cPCI Mini crate 475................................................................. 35

5 CML Firmware Update Instructions .................................................................................................. 36