8

5. Wear eye and face protection when testing, especially when testing brittle samples that have the

potential to shatter under force. Be aware of the dangers posed by potential energy that can

accumulate in the sample during testing. Extra bodily protection should be worn if a destructive

failure of a test sample is possible.

6. In certain applications, such as the testing of brittle samples that can shatter, or other applications

that could lead to a hazardous situation, it is strongly recommended that a machine guarding

system be employed to protect the operator and others in the vicinity from shards or debris.

7. When the gauge is not in use, ensure that the power is turned off.

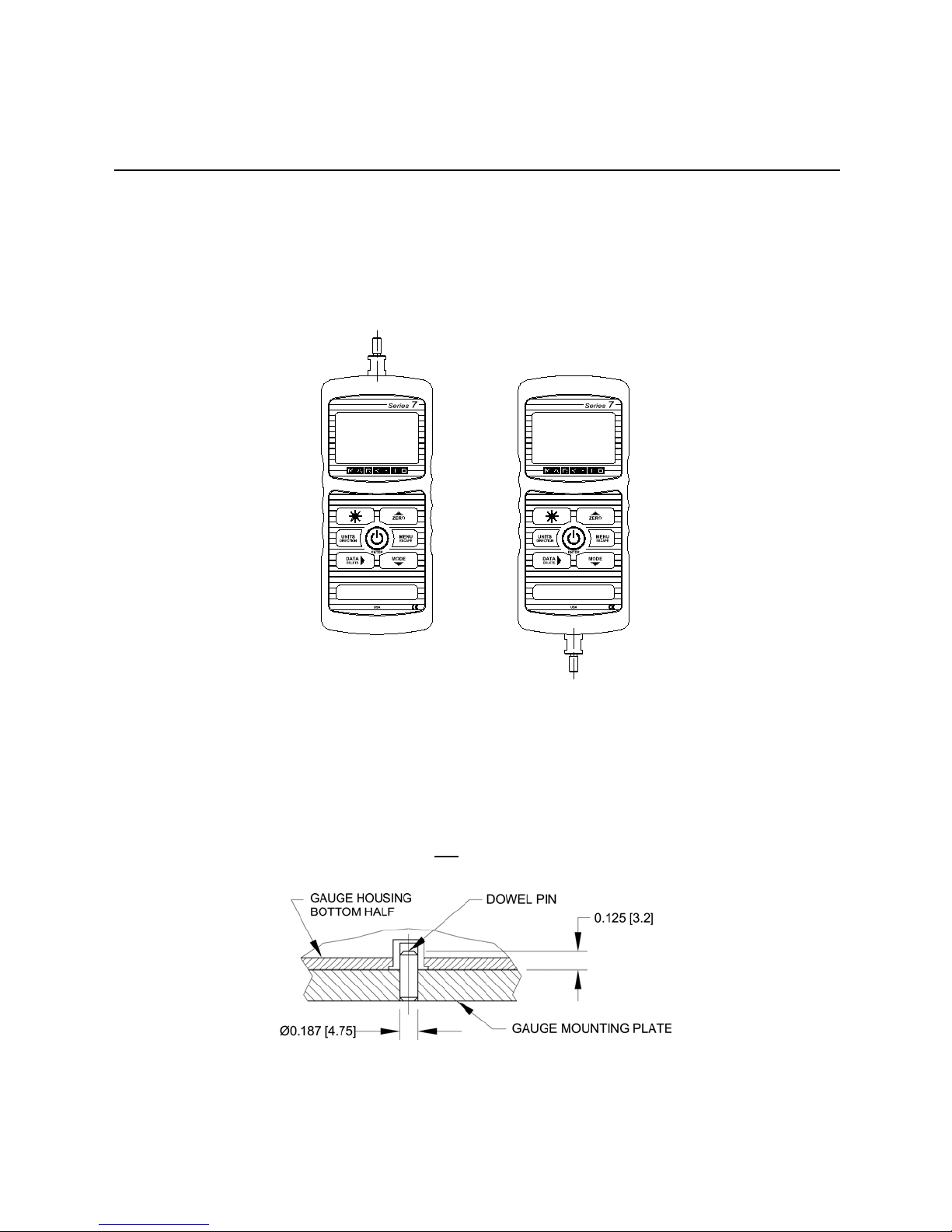

2GAUGEPOWER

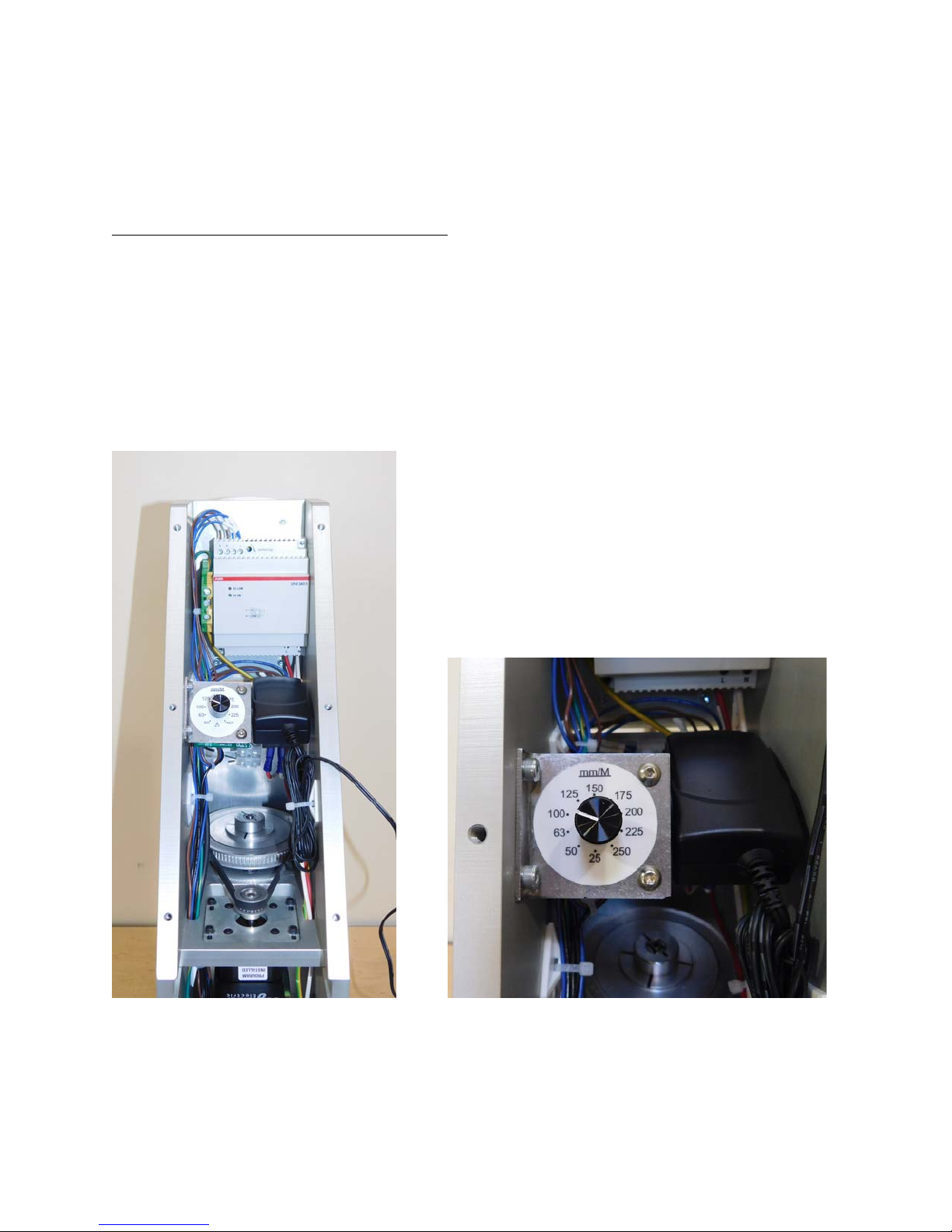

The gauge is powered either by an 8.4V NiMH rechargeable battery or by an AC adapter. Since the

batteries are subject to self discharge, it may be necessary to recharge the unit after a prolonged period

of storage. Plug the accompanying charger into the AC outlet and insert the charger plug into the

receptacle on the gauge (refer to the illustration below). The battery will fully charge in approximately 8

hours.

Caution!

Do not use chargers or batteries other than supplied or instrument damage may occur.

If the AC adapter is plugged in, an icon appears in the lower left corner of the display, as follows:

If the AC adapter is not plugged in, battery power drainage is denoted in a five-step process:

1. When battery life is greater than 75%, the following indicator is present:

2. When battery life is between 50% and 75%, the following indicator is present:

3. When battery life is between 25% and 50%, the following indicator is present:

4. When battery life is less than 25%, the following indicator is present:

5. When battery life drops to approximately 2%, the indicator from step 4 will be flashing.

Several minutes after (timing depends on usage and whether the backlight is turned on or

off), a message appears, “BATTERY VOLTAGE TOO LOW. POWERING OFF”. An audio

tone will sound and the gauge will power off.

The gauge can be configured to automatically power off following a period of inactivity. Refer to the Other

Settings section for details.

If battery replacement is necessary, it can be accessed by separating the two halves of the gauge. Refer

to the Setup section for details.

Serial connector

USB connector

Power input jack