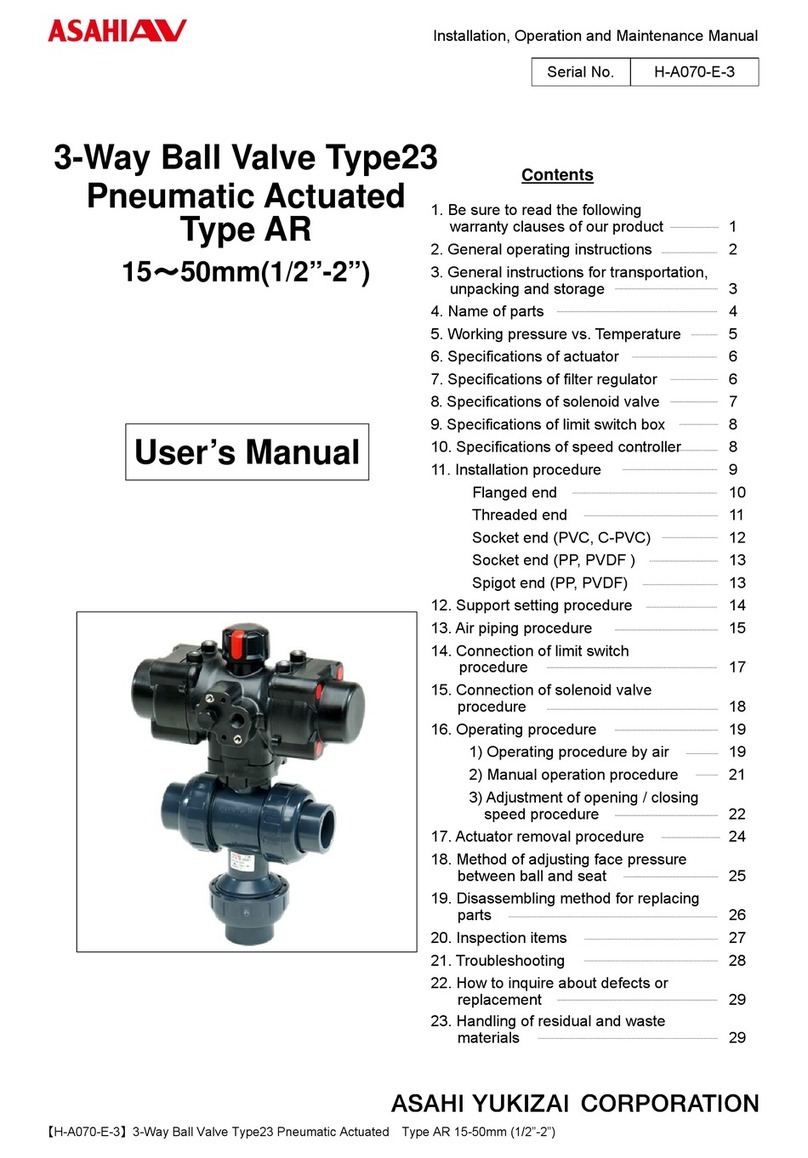

ASAHI 57P User manual

Installation Operation and Maintenance Manual

Butterfly Valve Type 57P 50-200mm (2”-8”)

Butterfly Valve Type 57P

Contents

(1) Be sure to read the following warranty

clauses of our product 1

(2) General operating instructions 2

(3) General instructions for transportation,

unpacking and storage 3

(4)Names of parts 4

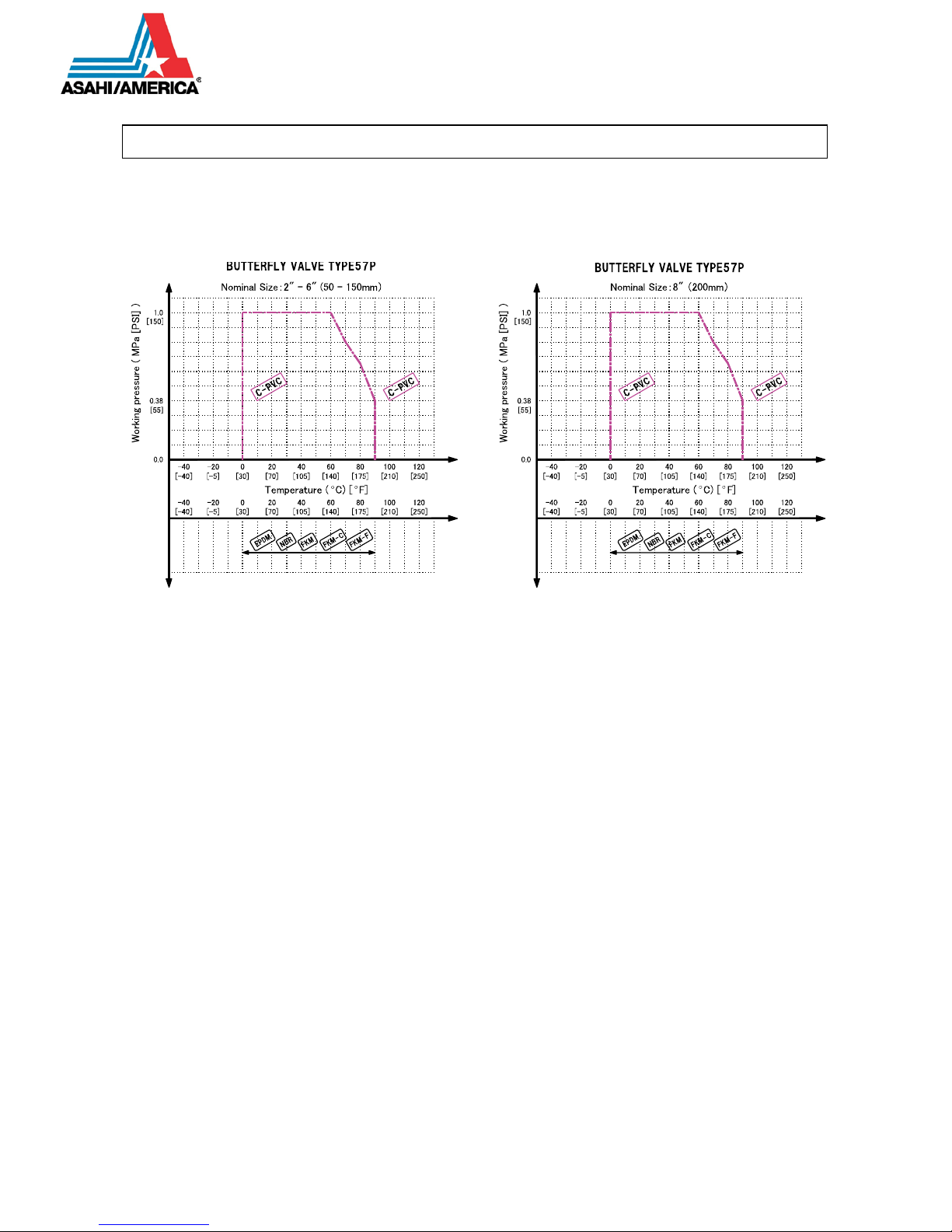

(5)Working pressure vs. temperature 6

(7) Installation procedure 7

(9) Operating procedure 11

(10) Disassembly and assembly procedure

for parts replacement 13

(11) Installation procedure for handle 15

(12)Adjustment procedure for

adjuster on gear type 16

(13) Inspection items 16

(14) Troubleshooting 17

(15) Handling of residual and waste materials 17

User’s Manual

Lever Type: 50-200 mm (2”-8”)

Body Material: CPVC

GearType: 50-200mm (2”-8”)

Body Material: CPVC

Installation Operation and Maintenance Manual

Butterfly Valve Type 57P 50-200mm (2”-8”)

1

This user’s guide contains information important to the proper installation, maintenance and safe use of an

Asahi/America product.Please store this manual in an easily accessible location.

<Warning & Caution Signs>

This symbol reminds the user to take caution due to the potential for serious injury or death.

This symbol reminds the user to take caution due to the potential for damage to the valve if used in

such a manner.

<Prohibited & MandatoryAction Signs>

Prohibited:When operating the valve, this symbol indicates an action that should not be taken.

Mandatory action: When operating the valve, this symbol indicates mandatory actions that must be

adhered to.

(1) Be sure to read the following warranty clauses of our product

-Always observe the specifications of and the precautions and instructions on using our product.

- We always strive to improve product quality and reliability, but cannot guarantee perfection. Therefore, should

you intend to use this product with any equipment or machinery that may pose the risk of serious or even fatal

injury, or property damage, ensure an appropriate safety design or take other measures with sufficient consideration

given to possible problems. We shall assume no responsibility for any inconvenience stemming from any action

on your part without our written consent in the form of specifications or other documented approval.

- The related technical documents, operation manuals, and other documentation prescribe precautions on selecting,

constructing, installing, operating, maintaining, and servicing our products. For details, consult with our nearest

distributor or agent.

-Our product warranty extends for one and a half years after the product is shipped from our factory or one year after

the product is installed, whichever comes first. Any product abnormality that occurs during the warranty period

or which is reported to us will be investigated immediately to identify its cause. Should our product be deemed

defective, we shall assume the responsibility to repair or replace it free of charge.

-Any repair or replacement needed after the warranty period ends shall be charged to the customer.

-The warranty does not cover the following cases:

(1) Using our product under any condition not covered by our defined scope of warranty.

(2) Failure to observe our defined precautions or instructions regarding the construction, installation, handling,

maintenance, or servicing of our product.

(3)Any inconvenience caused by any product other than ours.

(4) Remodelingor otherwise modifying our product by anyone other than us.

(5) Using any part of our product for anything other than the intended use of the product.

(6) Any abnormality that occurs due to a natural disaster, accident, or other incident not stemming from something

inside our product.

Warning

Caution

Installation Operation and Maintenance Manual

Butterfly Valve Type 57P 50-200mm (2”-8”)

2

(2) General operating instructions

- Using a positive-pressure gas with our plastic piping may pose a dangerous condition due to the

repellent force particular to compressible fluids even when the gas is under similar pressures used for

liquids. Therefore, be sure to take the necessary safety precautions such as covering the piping with

protective material. For inquiries, please contact us. For conducting a leak test on newly installed

piping, be sure to check for leaks under water pressure. If absolutely necessary to use a gas in testing,

please consult your nearest service station beforehand.

-Do not step on or apply excessive weight on valve. (It can be damaged.)

-Do not use the valve in conditionswhere the fluid may have crystallized.

(The valve will not operate properly.)

-Keep the valve away from excessive heat or fire. (It can be damaged, or destroyed.)

-Always operate the valve within the pressure vs.temperature range.

(The valve can be damaged or deformed by operating beyond the allowable range.)

-Allow sufficient space for maintenance and inspection.

-Select a valve material that is compatible with the media. For chemical resistance information, refer

to “CHEMICALRESISTANCE ONASAHIAVVALVE”.

(Some chemicals may damage incompatible valve materials.)

-Keep the valve out of direct sunlight, water and dust. Use cover to shield the valve.

(The valve will not operate properly.)

- Perform periodic maintenance. (Leakage may develop due to temperature changes or periods of

prolonged storage, rest, or operation.)

- Gear Operator Operation; we utilize a self-locking worm gear design on our manual operators.

This design allows flow control of the valve in intermediate positions in normal process conditions.

In applications where very high velocity, turbulence flow or vibration is present and an intermediate

setting is required, it is recommended to install a locking device. The locking device will prevent

the possibility of the valve drifting in severe condition form it is original intermediate setting.

Handle lock

Warning

Installation Operation and Maintenance Manual

Butterfly Valve Type 57P 50-200mm (2”-8”)

3

(3) General instructions for transportation, unpacking and storage

-When suspending and supporting a valve, take care and do not stand under a suspended valve.

-This valve is not designed to handle impactsof any kind. Avoid throwing or dropping the valve.

-Avoid scratching the valve with any sharp object.

-Do not over-stack cardboard shipping boxes. Excessively stacked packages may collapse.

-Avoid contact with any coal tar creosote, insecticides, vermicides or paint.

(These chemicals may cause damage to the valve.)

-When transporting a valve, do not carry it by the handle.

- Store products in their corrugated cardboard boxes. Avoid exposing products to direct sunlight, and

store them indoors (at room temperature). Also avoid storing products in areas with excessive

temperatures. (Corrugated cardboard packages become weaker as they become wet with water or

other liquid. Take care in storage and handling.)

-After unpacking the products, check that they are defect-free and meet the specifications.

Installation Operation and Maintenance Manual

Butterfly Valve Type 57P 50-200mm (2”-8”)

4

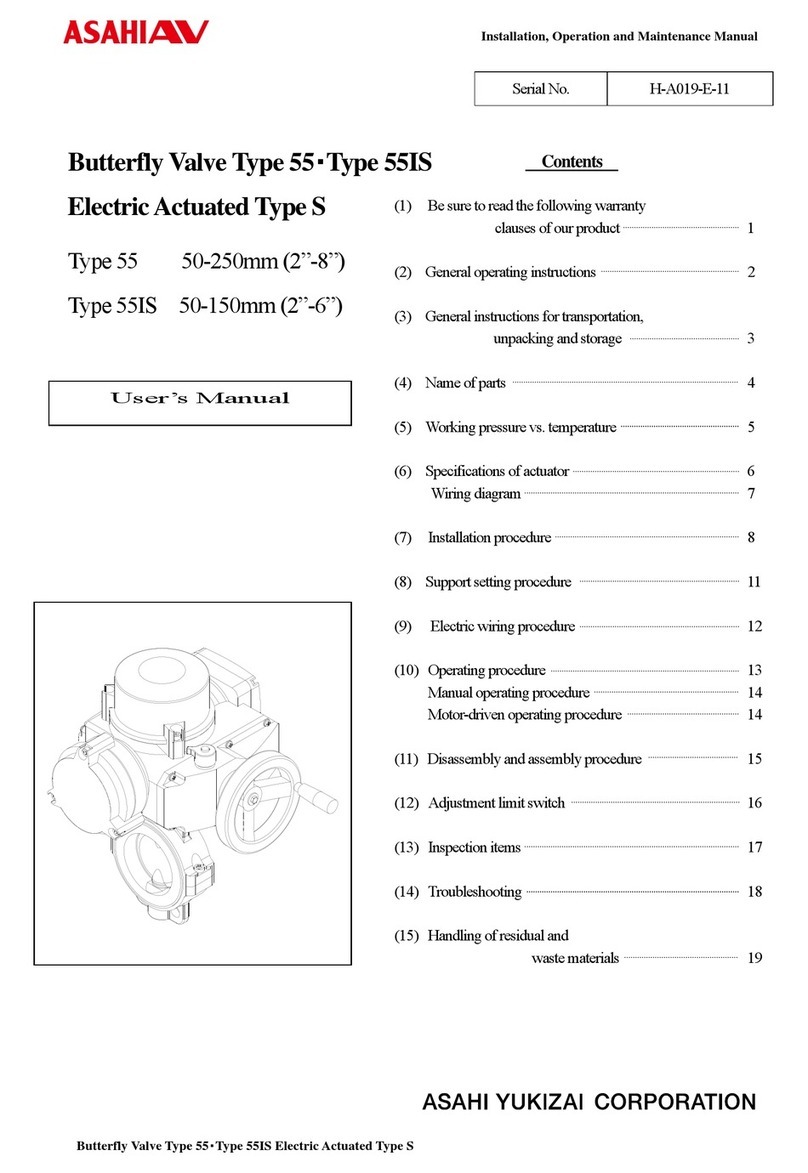

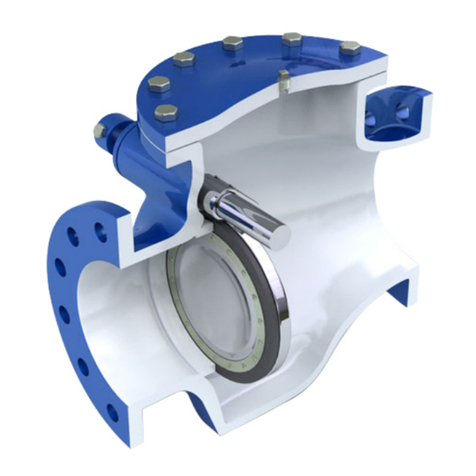

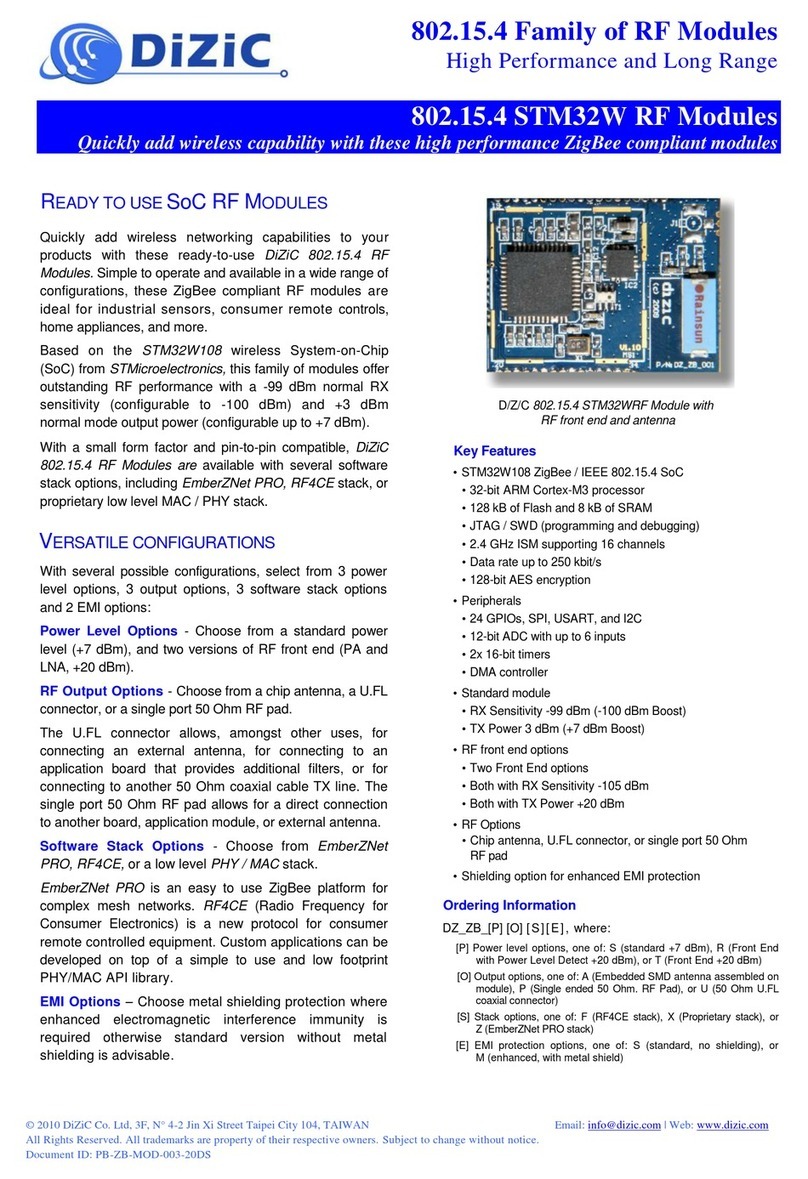

(4) Names of parts

Type 57P(Lever/ GearType): 50-200mm (2”-8”)

Body Material: CPVC

No.

Description

No.

Description

No.

Description

[1]

Body

[18]

Pin

[157]

Screw (F)

[2]

Disc

[19]

Spring

[158]

Gasket (L)

[3]

Seat

[21]

Bolt (A)

[182]

O-Ring (H)

[6]

O-Ring (C)

[22]

Locking Plate

[183]

Seat Bush (A)

[7]

Stem

[23]

Screw (B)

[184]

Seat Bush (B)

[8]

Stem Holder (A)

[24]

Cap (A)

[185]

O-Ring (I)

[16]

Handle (A)

[25]

Gear Box

[186]

Rubber + Washer

[17]

Handle Lever

[28]

Bolt (C)

Installation Operation and Maintenance Manual

Butterfly Valve Type 57P 50-200mm (2”-8”)

5

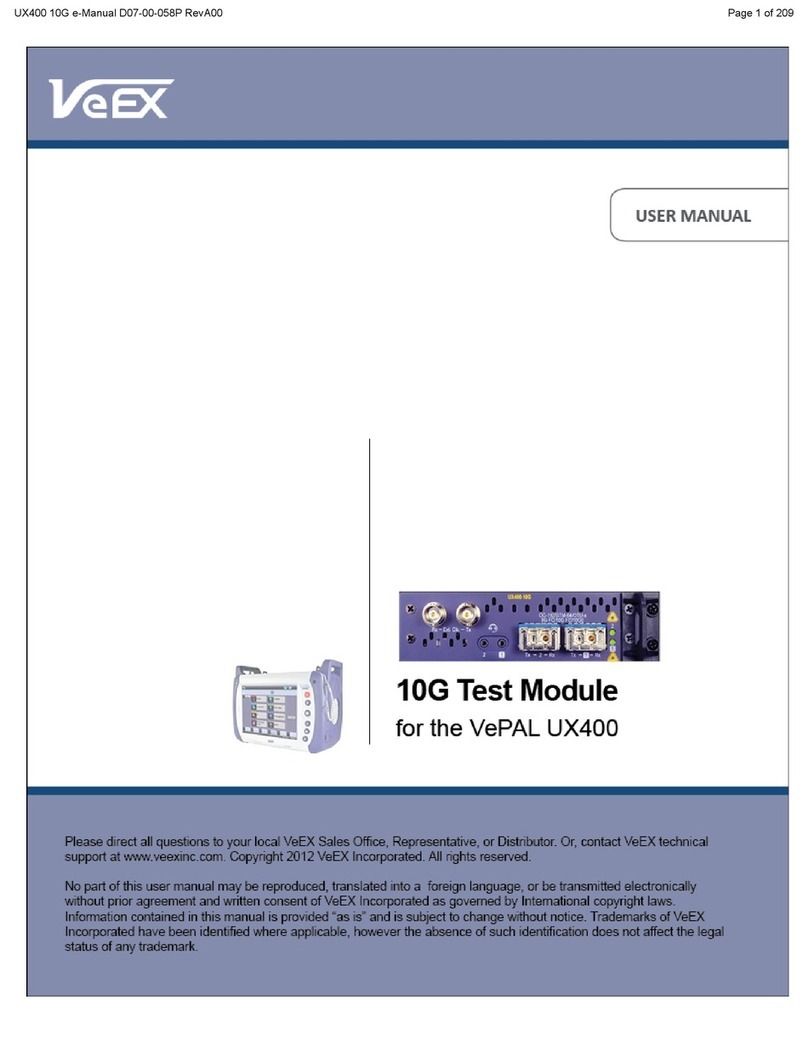

Type 57P(Gear Type): 50-200mm (2”-8”)with Handle Lock (Option)

No.

Description

[161]

Lock Plate (A)

[162]

Lock Plate (B)

Installation Operation and Maintenance Manual

Butterfly Valve Type 57P 50-200mm (2”-8”)

6

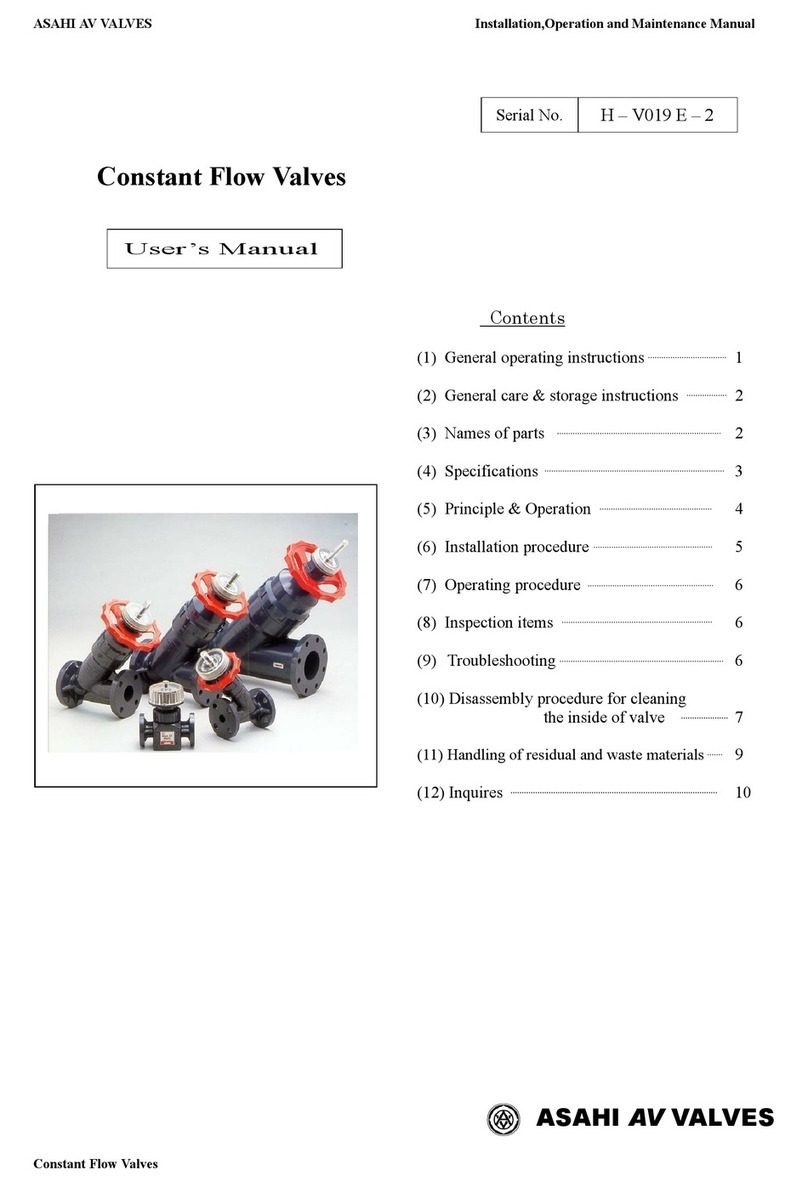

(5) Working pressure vs. temperature

Installation Operation and Maintenance Manual

Butterfly Valve Type 57P 50-200mm (2”-8”)

7

(7)Installation procedure

-When suspending and supporting a valve, take care and do not stand under a suspended valve.

-Be sure to conduct a safety check on all hand and power tools to be used before beginning work.

- Wear protective gloves and safety goggles as fluid remain in the valve even if the pipeline is empty.

(You may be injured.)

- When installing a pipe support by means of a U-band or something similar, take care not to over-tighten.

(Excessive force may damage the pipe.)

- When installing pipes and valves, ensure that they are not subjected to tension, compression,

bending, impact, or other excessive stress.

- Do not install the valve with the disc fully closed. (The disc may pinch into the seat, resulting in a high

operating torque and preventing the valve from operating properly.)

-Use flat faced flanges for connection toAV Valves.

-Ensure that the mating flanges are of the same standards.

-The gasket is unnecessary. (The seat carries out the role of the gasket.)

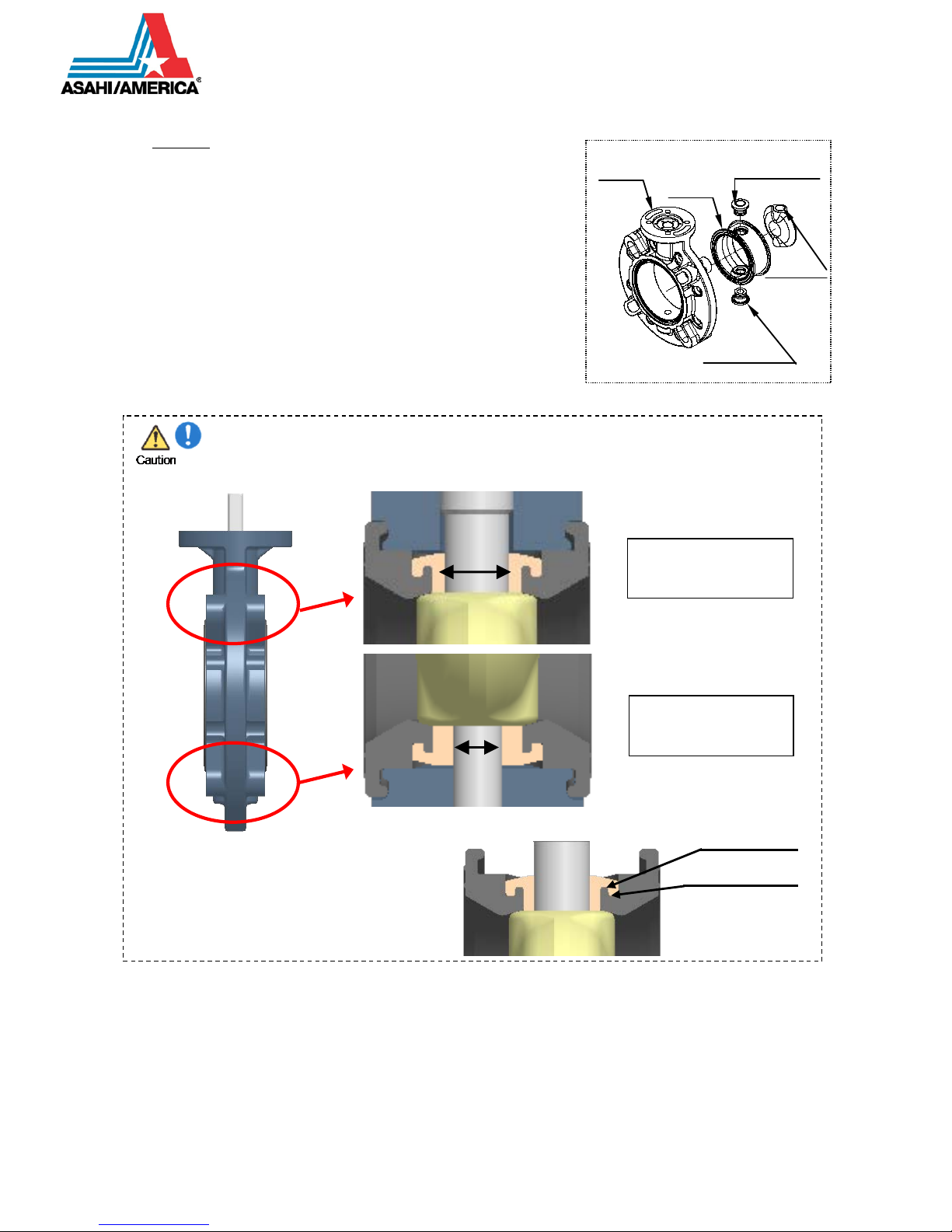

- The valve disc is in the position indicated by solid

lines in figure to the right prior to shipment from

the factory. If the valve is opened or closed after

unpacking, it must be reset in this position before

installation. Failure to do so will result in damage

to the surface of the valve seat during handling and

installation.

-Care must be used during piping installation to ensure that the pipes or flanges are properly aligned so that

the valve disc does not contact them in any setting. Misalignment as in figure below will result in

damage to the valve.

NOTRECOMMENDED

RECOMMENDED

INTERFERENCE OF THE DISK

Installation Operation and Maintenance Manual

Butterfly Valve Type 57P 50-200mm (2”-8”)

8

In case of an abutting thick walled flange and pipe, shave the flange or the pipe inner diameter in order to avoid contact of

pipe and disc. If the inside diameter of the connecting pipe is larger than dimension D below, shaving is not necessary.

Unit: mm (inch)

Nominal Size

Diameter D

50mm(2”)

43mm (1.69”)

80mm(3”)

67mm (2.64”)

100mm (4”)

91mm (3.58”)

150mm (6”)

137mm (5.39”)

200mm (8”)

179mm (7.05”)

●Torque Wrench ●Spanner Wrench

Procedure

1) Install the valve between flanges and open the valve slightly.

*The disc[2] is prevented from overflowing. (The disc[2] is damaged.)

2) Insert bolts, set nuts and washer and tighten the bolts and nuts temporarily by

hand.

- When you insert a valve between flanges,

please insert after extending the fields of

flanges fully. (If you insert a valve by

force without fully extending fields of

flanges, a liner may be turned over,

pinched, and suffer a crack.)

Necessary items

Installation Operation and Maintenance Manual

Butterfly Valve Type 57P 50-200mm (2”-8”)

9

The parallelism and axial misalignment of the flange surface should be under the values shown in the following table

-The parallelism and axial misalignment of the flange surface should be under the values shown in

the following table to prevent damage the valve. (Afailure to observe them can cause destruction

due to stress application to the pipe)

Unit : mm (inch)

Nom. Size

Axial Misalignment

Parallelism (a –b)

50 -80mm

(2”-3”)

1.0

(0.04)

0.8

(0.03)

100-150mm

(4”-6”)

1.0

(0.04)

1.0

(0.04)

200mm

(8”)

1.5

(0.06)

1.0

(0.04)

3) Tighten the bolts and nuts gradually with torque wrench to the specified torque in a diagonal manner.

-Tighten the bolts and nuts gradually with a torque wrench to thespecified

torque level in a diagonal manner.

Recommended torque value Unit:N・m {kgf・cm}[lb・inch]

Nom. Size 50 (2”) 80, 100 mm (3”,4”)

Torque value 22.5 {230} [200] 30.0 {306} [266]

Nom. Size 150 mm (6”) 200mm (8”)

Torque value 40.0 {408} [355] 55.0 {561} [488]

Caution :Avoid excessive tightening.(The valve can be damaged.)

(AxialM

isalignment)

(Parallelism)

Installation Operation and Maintenance Manual

Butterfly Valve Type 57P 50-200mm (2”-8”)

10

<ANSI Standard>

Body Material: CPVC

Dimension of Insert Bolt

Nom. Size

Bolt (Minimum)

Nut Washer

mm

inch

d

L

S

50

2”

5/8”-11

125mm (4.92”)

35mm

(1.38”) 5/8”-11 5/8” Flat

(0.63”)

80

3”

130mm (5.12”)

100

4”

145mm (5.71”)

150

6”

3/4"-10

175mm (6.89”)

40mm

(1.57”)

3/4"-10

3/4" Flat

(0.79”)

200

8”

190mm (7.48”)

Installation Operation and Maintenance Manual

Butterfly Valve Type 57P 50-200mm (2”-8”)

11

(9) Operating procedure

-Do not use the valve to fluid containingslurry. (The valve will not operate properly.)

-The installed valve must never be opened or closed when foreign matter such as sand is present in

the pipeline.

-Do not exert excessive force in closing the valve.

-When operating the handle, be sure to do so with your hand. (Using a tool may damage the handle.)

1) Open and close the valve by turning handle smoothly. (Turn clockwise to close and counterclockwise to open.)

2) In case of lever type (50-200 mm {2”-8”}), the direction of handle issame as the disc as shown in Fig. 9-1.

・For the full-shut (Close) position, the handle is perpendicular to the piping axis direction.

・For the full-opened position, the handle is parallel to the piping axis direction.

Full-Shut (Close) Position Full-Open Position

3) In case of gear type (50-200 mm {2”-8”}), the indicator shows the position of the disc on the top of gear box.

(Fig.9-2, Fig.9-3)

・For the full-shut (close) position, the indication shows Shut (S).

・For the full-opened position, the indication shows Open (O).

Full-Shut (Close) Position Full-Open Position

Fig.9-2

-The adjustments for full-opened and full-shut position are step-less, and it can be done with the adjuster.

Fig. 9-1

Installation Operation and Maintenance Manual

Butterfly Valve Type 57P 50-200mm (2”-8”)

12

Technical Data for Operation

Nominal Size

mm

(inch)

Stem Torque

(N・m) Length of Lever and

Diameter of Handle (mm) Required Operating Force

(N)

Seal Lever Type GearType Lever Type Gear Type

50mm

(2”)

10 220 160 46 5

80mm

(3”)

20 250 160 80 11

100mm

(4”)

30 250 160 120 16

150mm

(6”)

65 320 160 205 34

200mm

(8”)

165 400 160 395 87

Note : Data mentioned in the table above is reference only.

These data are measured in standard condition and it slightly differs depending on conditions.

Required Operating Force is the data by turning handle with both hands.

Installation Operation and Maintenance Manual

Butterfly Valve Type 57P 50-200mm (2”-8”)

13

(10) Disassembly and assembly procedure for parts replacement

- The handle part can be removed with line pressure present. The stem retainer can't be removed with

line pressure present. If stem retainer needs to be removed, there can not be line pressure present.

- Wear protective gloves and safety goggles as fluid remain in the valve even if the pipeline is empty.

(You may be injured.)

-When installing pipes and valves, ensure that they are not subjected to tension, compression, bending,

impact, or other excessive stress.

-Do not change or replace valve parts under line pressure.

●Protective Gloves ●Vise ●Circular Stick (Plastic or Wood)

●Goggles ●Grease (Silicone) ●Pressing Machine ●Screwdriver (+)

●Spanner Wrench ●Square Lumber ●Hammer ●Screwdriver (-)

<< Disassembly >>

Procedure

1) Drain fluid completely from the pipeline.

2) Leave the valve slightly opened.

3) Loosen the connecting bolts and nuts.

4) Remove the valve from the pipeline.

Lever Type <Nominal size 50-200mm (2”-8”)

5) To remove handle [16], first take off the cap [24] by using screw

driver (–) and release bolt [21] by using socket wrench, then pull

up the handle [16] while holding handle lever [17].

6) To take off locking plate [22], release 4 self-tapping screws [23] by using screw driver (+) and take off stem holder [8].

GearType <Nominal size 50-200mm (2”-8”)

5) Loosen set bolt [28] for gear box [25] and pull off the gear box upward with gasket [158]*.

6) Remove the stem holder [8]. Release 4 tapping screws [157]by using screw driver (+).

Lever & Gear Type

7) Hold flat surface of Stem [7] with vise and pull off valve body [1].

8) Insert the screw driver (-) between body [1] and seat [3]. Disc [2] and seat [3] are extruded by using screw driver (-).

9) Remove the disc [2], seat bush (A) [183] and seat bush (B) [184] from the seat [3].

10) Remove the O-ring (C) [6] from the stem [7].

Necessary items

Body Seat Bush (A)

Seat Bush (B)

Disc

Seat

Installation Operation and Maintenance Manual

Butterfly Valve Type 57P 50-200mm (2”-8”)

14

<<Assembly >>

Procedure

1) Before starting assembly, grease (Silicone) should be spread on the

O-ring (C) [6] and O-ring (I) [185].

2) Put the O-ring (C) [6] onto the stem [7]. Put the O-ring (I) [185]

onto the stem bush (A) [183] and B [184].

3) Grease (Silicone) should be spread on the top and bottom disc [2],

the stem of the seat [3].

4) Put the disc [2], seat bush (A) [183] and seat bush (B) [184] onto the

seat [3]. “The set of seat -disc”call for combined parts.

5) Put it into the state of open the valve slightly. Insert the set of seat -

disc [3] into the body [1].

- Make certain stem hole of seat are properly aligned. The upper side stem hole of seat bush (A) [183]

has lager than seat bush (B) [184] of lower side. When the stem bush is assembled oppositely, the

stem [7] cannot be inserted.

-Make certain tabs are properly aligned.

6) Insert the stem [7] of the body [1].

7) Install stem holder [8] onto valve body [1] with countersunk holes facing up using 4 screws [157].

8) To install lever or gear operator reverse disassembly procedure #5).

* Make certainline scribed ontop of stem [7]indicates disc [2] position while installing stem[7].

9) After assembly, make sure that the valve can be fully opened and closed smoothly.

Body Seat Bush A

Seat Bush B

Disc

Seat

Upper side:

Stem hole is large size

Lower side:

Stem hole is small size

Concave part of seat bush

Convex part ofseat bush

Installation Operation and Maintenance Manual

Butterfly Valve Type 57P 50-200mm (2”-8”)

15

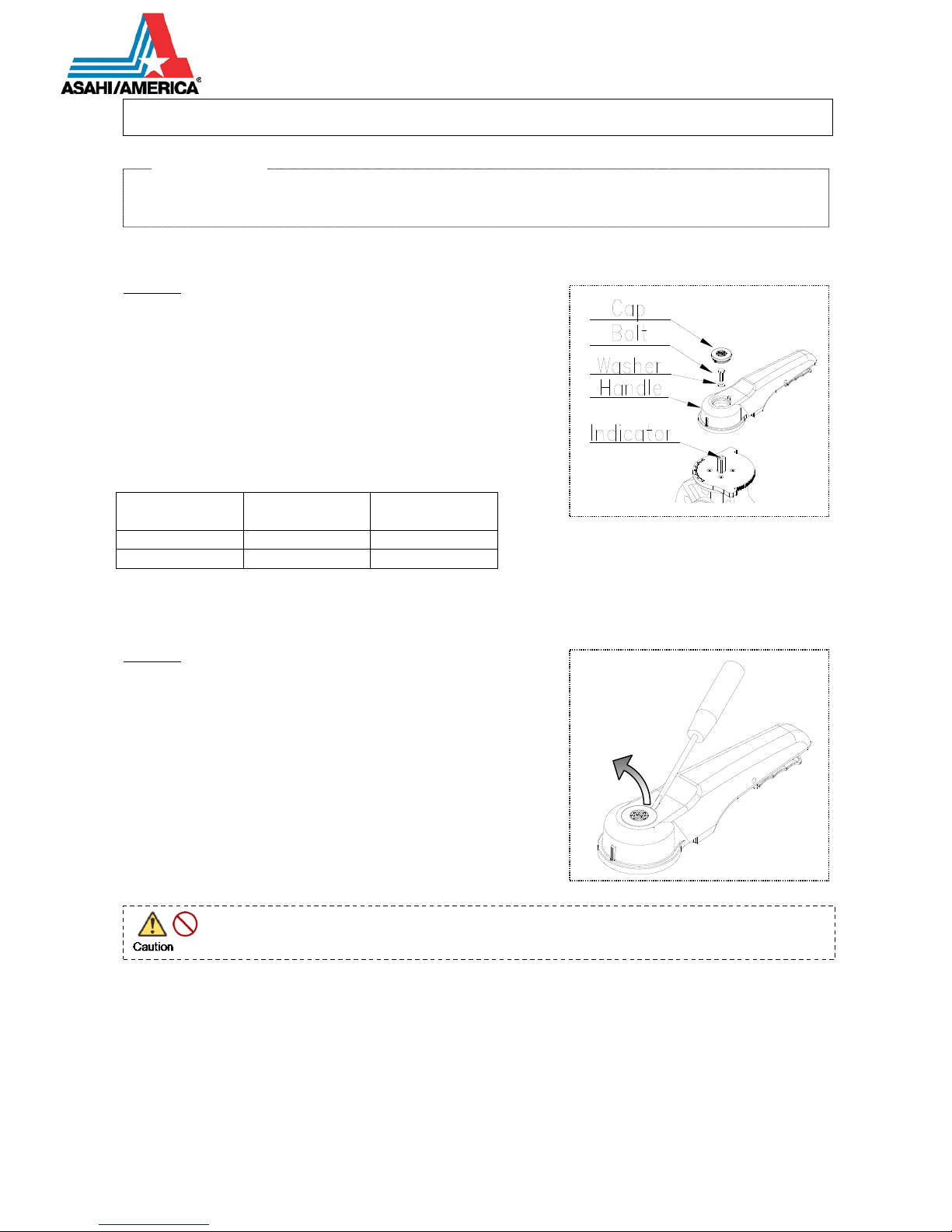

(11) Installation procedure for handle

●Plastic Hammer ●Socket Wrench ●Screw Driver(–)

●Goggles ●Protective Glove

《Installation》

Procedure

1) Install the handle on the stem. Set the direction of handle in the

indication line at the top ofstem.

2) Fix the handle at the top of stem with the attached bolts and washer

by using socket wrench.

3) Set the convex part at the side of the cap and the concave of the

handle, and set in the cap by striking lightly by using a plastic

hammer.

Nominal Size

50-100mm

(2”-4”)

150-200mm

(6”-8”)

Bolt Size

M6×15L

M8×15L

Socket Size

10

13

《Remove》

Procedure

1) To remove the cap, push up the side of the cap by using screw driver (-).

2) Loose the bolts and washer by using socket wrench, then remove the

handle.

-Do not give any unjust force to cap, in installing or removing the cap. (It can be damaged)

Necessary items

Installation Operation and Maintenance Manual

Butterfly Valve Type 57P 50-200mm (2”-8”)

16

(12)Adjustment procedure for adjuster on gear type

●Safety Glove ●AllenWrench ●Spanner Wrench

The adjustments for full-opened and full-shut position are step-less, and it can be done with the adjuster.

Adjustment for Full-shut (Full-opened) position

1) In Case of Gear Type

Remove the rubber cap of Full-closing (Full-opening) adjuster.

2) Loosen the first adjuster hex-bolt completely by Allen wrench or

spanner wrench.

3) Adjust the disc of valve to required position.

4) Tighten the adjuster hex-bolts.

5) In Case of Gear Type

Put the rubber cap of Full-closing (Full-opening) adjuster back on

gearbox by hand.

(13) Inspection items

- Perform periodic maintenance. (Leakage may develop due to temperature changes or over periods of

prolonged storage, rest or operation.)

Inspect the following items.

(1) Check for flaw, crack, or deformation on the valve.

(2)

Check for leaks to the outside.

(3)

Check for the deformation of seat due to improper installation of valve.

(4)

Check for the smoothness of handle operation..

Necessary Items

Adjuster for Full

-OpenedPosition

Adjuster of Full-Shut Position

GearType

Rubber Cap

Installation Operation and Maintenance Manual

Butterfly Valve Type 57P 50-200mm (2”-8”)

17

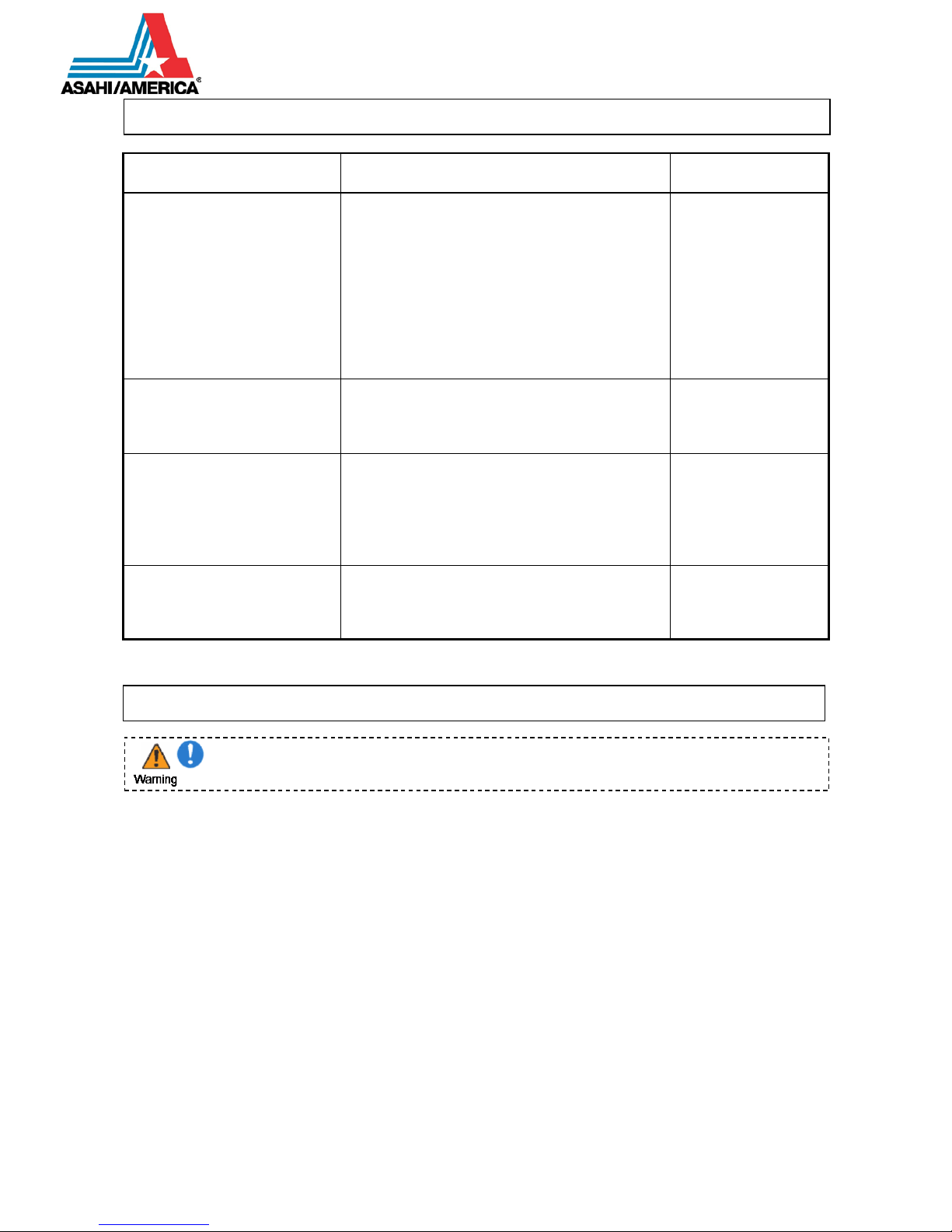

(14) Troubleshooting

Phenomenon Cause Treatment

Fluid leaks from the valve even

when the valve is fully closed.

1) The adjuster is not set correctly.

2) The seat is damaged or worn.

3) Foreign materials are caught.

4) The disc is damaged or worn.

5) The connecting bolts are over tightened or

tightened unevenly.

Adjust the adjuster.

Replace the seat.

Clean it up.

Replace the disc.

Adjust and retighten.

Fluid leaks to the outside.

1) The seat is damaged or worn.

2) The connecting bolts are not tightened in

proper torque or evenly.

Replace the seat.

Adjust and retighten.

The handle does not work

smoothly.

1) Foreign materials have adhered.

2) The gear box is damaged.

3) The connecting bolt is over tightened.

Clean it up.

Repair or replace.

Adjust and retighten.

Valve does not operate 1) The gear box is damaged

2) The stem is damaged.

Repair or replace.

Replace the stem.

(15) Handling of Residual and Waste Materials

- Make sure to consult a waste treatment dealer for recommendations on the proper disposal of plastic

valves. (Poisonous gas is generated when the valve is burned improperly.)

Installation Operation and Maintenance Manual

Butterfly Valve Type 57P 50-200mm (2”-8”)

Butterfly Valve

Type 57P: 50-200mm (2”-8”)

Asahi/America Inc.

Information in this manual is subject to change without notice.

Table of contents

Other ASAHI Control Unit manuals

Popular Control Unit manuals by other brands

Cobalt Digital Inc

Cobalt Digital Inc 9934-AUD-PRO product manual

DIEL

DIEL MT 200 Installation and instruction manual

Panblast

Panblast BAC-RC-PB-0274 Product Operating Manual

WAGNER

WAGNER EPG-Sprint X operating manual

Burkert

Burkert 6027 operating instructions

Group Four Transducers

Group Four Transducers GLDM 64.1 Technical manual