ASAHI CSR-3005E User manual

OIL SPILLAGE DETECTOR

APOLARM-C

Electrostatic Capacity Type

INSTRUCTION MANUAL

(Nov/2011)

ASAHI KASEI TECHNOSYSTEM CO.,LTD.

Rev. 1.0

Model CSR-3005E

1

OIL SPILLAGE DETECTOR

APOLARM-C

INSTRUCTION MANUAL

CONTENTS page

1. Introduction 2

2. Main features 2

3. General specifications 3

4. Functional theory of "Apolarm-C" 4

5. Components 6

5-1. Detector Apolarm-C 6

5-2. Transducer 8

5-3. Dry pit attachment 11

6. Wiring and operation 12

6-1. Wiring 12

6-2. Operation 13

6-3. Oil leakage detection test 13

7. Installation of Apolarm-C 14

7-1. Determination of place for installation 14

7-2. Effective installation method 14

7-3. Cautions for installation work 17

8. How to Install Explosion-Proof Wiring 19

8-1. Selection of installation site 19

8-2. Wiring of intrinsically safe circuit 20

8-3. Applicable cable 20

8-4. How to discriminate external wiring of intrinsically safe circuit 20

8-5.Interconnectionandbranching 20

8-6.Panelwiringatnon-hazardousarea 21

8-7.Otherwiring 21

8-8.Grounding 22

2

In the event of oil leaking out due to any accidental cause at an industrial lot

where a large volume of oil is handled, the most important matter is to detect

its occurrence without delay and to dispose of it quickly and adequately.

"Apolarm-C" is intended to detect oil leakage that may take place at tank or

pump yard in an area where oil is handled. This oil leakage detector has high

reliability and excels in the capability of detecting high-viscous oils and can

detect leaking oil even in such adverse surroundings where dust and

whitewash tend to be produced.

◎This is a detector produced with importance placed on pursuance for reliability.

* To improve strength against waves:

This detector is shaped unsymmetrical between upper and lower parts from the draft line

as border.

This shape works to make this device stable against the up-and-down motion of waves.

As the transducer is equipped with delay circuit, there is no fear of misinformation taking

place.

* To prevent failure of detection:

The underwater section and electrodes of floater are so structured as to be safe from

whitewash-caused short circuit.

* Even if dust or grease is caught on the device surface, there is no fear of miss signal being

sent out.

◎Able to detect sticky oils as well.

◎Permits optional selection of oil layer depth to detect.

*It is possible to detect leaked oil up to 50mm oil layer thickness by setting adequate

electrodes, (optional supply)

◎For both floater and cable, self-fire extinguishing type resin is used as material.

This resin has high oil and chemicals resistance as well.

◎Apolarm-C is a fail-safe type.

In the event power failure to transducer or cable disconnection occurs, warning signal is

given out.

◎ As this detector is made in an intrinsic safety type explosion-proofing structure,

Apolarm-C can be installed at any hazardous place.

◎It is easily observed the function in the field by means of actuating lamp on the Detector.

◎It is easily fined out the difference of trouble such as oil alarm or system alarm by the two

lamps on the Transducer.

◎The Transducer is provided with a delay timer of 1 ~1 0 (adjustable) second to prevent the

signal error caused by water wave and wind.

Introduction

Main features

3

Detectable objects : Petroleum items (crude oil, heavy oil, light oil, gasoline, lubricants, etc.),

animal & vegetable, oil, olive oil, etc., organic solvents and others.

■ Detector (Apolarm-C)

Model: CSR-3005E

Sensitivity: 3 - 5 mm

Objects to detect: Crude oil, gasoline, light oil, kerosene, heavy oil, lubricant, solvent, animal

& vegetable oils

Structure: Water-proof structure

Material: High impact resistance P. V. C. for Floater, SUS316 for Detector electrodes

Weight: About 2.6 kg

Cable: Synthetic rubber cable (flame-retardant, flexible, oil-resistant, weather-proof) 12

meters attached, 2-cores 0.75 mm each

Maximum permissible cable length: 2 Km (2 mm cable)

Ambient temperature : -20 ~ +60℃

■Transducer

Model: AS-40E (built-in delay circuit, wire disconnection and short circuit alarm)

Delay timer: Approx. 1-10 second (adjustable)

Housing: See dimension figure

Weight: About 800g

Power source: AC100/110V, 200/220V, 50/60Hz

Power consumption: Approx. 2VA

Output circuit : Contact output (type C ×2) oil alarm 1C & system alarm 1C

Contact capacity: AC250V, 4A DC30V, 4A

Ambient temperature : -10 ~ +50℃

Ambient humidity : ≦95% R. H.

Structure : Intrinsic safety type explosion-proof construction ⅡCT4

Short circuit current of input circuit: (max.) DC121. 6mA

Open circuit voltage of input circuit: (max.) DC 14.3V

Oil alarm: LED (green) light is on under normal operation

System alarm: LED (red) light is off under normal operation

General s

p

ecification

4

■Detector

(Fig.4-1)

(a) Way of detection

When all of the detecting electrodes come in contact with oil at an oil depth from 3 to 5

mm, this device functions to detect the presence of oil there.

When any of the electrodes, even only one electrode, is in contact with water, no detection

signal is sent out from the device.

The purpose of this design is to prevent the device from giving out erroneous signals

influenced by the force of waves, wind, etc. when there is no abnormal existence of oil.

(b) Theory

Detector floats on water with its electrode points in touch with water surface about 2 mm.

(in case of 3-5 mm range detection depth).

Inside the detector are set high frequency wave oscillation circuit, AC bridge circuit,

switching circuit and constant voltage power source circuit To the AC bridge circuit is

impressed high frequency (approx. 1 MHz) power, and part of the bridge is connected in

parallel to the three electrodes.

Namely, the AC bridge circuit monitors the changes in electrostatic capacity around the

electrodes.

When oil flows out on water surface, and it comes to contact the electrodes, the

electrostatic capacity around them largely varies to cause the balance in the AC bridge

circuit to be reversed.

This variation is caught and amplified at the switching circuit subsequently, it is turned

into current signal at the constant voltage power source circuit and this signal is sent to

transducer. When oil is detected at approx. 14 mA DC under ordinary conditions, this

signal becomes approx. 4 mA DC.

Fig. 4-1 Detector

∞

N

B

A

i

P'

N'

Between B &Earth Im

p

edance

High frequency wave

oscillator Detecting electrodes

Oil de

p

th

Water

Earth

Switching

circuit

Power source

Functional theor

y

of “

Ap

olarm-C”

5

■Principle and structure

(Fig.4-2)

Model CSR-3005E is an intrinsic safety type explosion-proof transducer.

Floater has three electrodes, and high frequency current provided from its detector circuit

checks the electrostatic capacity at the electrode section.

When oil flows out onto water surface, the electrodes have to contact water through the oil

layer, which causes their electrostatic capacity to vary largely.

This variation in electrostatic capacity is detected and amplified in the detector circuit

causing the transducer to work and put out contact signals.

①

②

③

④

⑩

⑨⑧⑦⑥⑤

P2

N2

E2

P1

N1

E1

B1

B2

OV

C1

A1

C2

A2

P

N

E

100~

110V

200~

220V

G

①Dry pit attachment: The detector electrode will be grounded when the water level is

getting low in the pit.

②Ball float: It prevents the detector from leaning because of the weight of a cable when

water level is unstable.

③APOLARM-C:CSR-3005E

④Apolarm guide: It prevents the detector from leaning and moving because of water

current and the level is unstable.

⑤Angle iron: It holds the Apolarm guide.

⑥Junction box: Use this box for the cable connection if the distance between detector and

transducer is more than 12 meters.

⑦Extension cable

⑧Transducer:AS-40E

⑨Transducer Box: Use this box if the environmental condition is not good for the

transducer. )

⑩Power and signal cable

※ ①,②,④,⑤,⑥,⑦,⑨and ⑩are optional accessories.

Fig4-2

6

114

55

300

Float P.V.C

WELDED

Gland packing

Lamp

Fig.5 Structure of Apolarm-C

Electrode

(SUS-316)

5-1. Detector Apolarm-C

(1) Structure of Apolarm-C

CSR-3005E

Water-weathering structure

Floater is composed of three resin moldings and their jointing faces are welded.

The section through which cable is led out is double-sealed by means of grand packing and

bonding agent.

(2) Detectable oils

As written in specifications, this detector can detect the presence of petroleum items,

animal oils, organic solvent solutions, etc.

Apolarm-C has a structure capable of detecting such high viscosity oils as C heavy oil,

minus heavy oil, grease, as well.

(a) Necessary conditions to be detected

①To be smaller than water in specific gravity.

②To be not water-soluble

(Ether, methanol, etc. cannot be detected.)

③Dielectric constant is not larger than 5.

Com

p

onents

7

Dielectric constants and specific gravity of main oils:

Table 5-1

Petroleum items

Animal, vegetable and other oils

Soybean oil

Cotton-seed oil

Caster oil

Olive oil

Linseed oil

Turpentine oil

3.2

3.1

4.8

3.1

3.4

2.2

0.92

0.92

0.96

0.9

0.93

0.87

(b) Oil layer depth range detectable by Apolarm-C

Oils with fluidity can be detected by Apolarm-C when the oil layer reaches a 3 ~ 5 mm

range thickness that is nearly constant regardless of the kind of oil.

As to high viscosity oil, its presence is detected when the respective oil layers which came

in contact with each of all the electrodes reach a 3 ~ 5 mm range thickness.

The item-wise thickness of oil layer detected is as shown in the following table 5-2.

Items Dielectric constant Specific gravity

Crude oil

Naphtha

Gasoline

Jet engine fuel

Kerosene

Xylene

Benzene

Toluene

A heavy oil

B heavy oil

C heavy oil

Paraffin oil

Styrene

Machine oil

Lubricant oil

2.2 - 2.5

2.0

2.0

1.7

2.0

2.3

2.3

2.3

2.0

2.2

2.3

2.2 - 4.7

2.4

2.1

2.3-3

0.7

0.76

0.83

0.78

0.87

0.87

0.87

0.85

0.89

0.93

0.85 or around

0.89

0.93

0.9 - 0.93

8

Table 5-2

Kind of oil

Water

temperature

(℃)

Oil

temperature

(℃)

Spec.

Gravity

Viscosity

(CP)

Detected

oil layer

(mm)

Kerosene

Turbine oil

A-Heavy oil

B-Heavy oil

C-Heavy oil

13.5

13.5

13.5

13.5

25

14.0

13.5

13.5

13.5

25

0.796

0.877

0.846

0.91

0.925

1.6

330

4.9

―

300

3.4

3.1

3.0

3.6

3.5

(c) Change of detectable oil layer thickness

Detectable oil layer thickness can be changed by changing electrode length (max. limit 50

mm). When ordering for us, please designate the oil layer thickness you wish the device

made detection of leaking oil at.

(3) Materials of Apolarm-C

(a) Floater

Floater uses impact-resistant PVC as material.

This resin is self-fire extinguishing type that has excellent chemicals resistant and

whether proofs properties.

Use of BTX group solvents will cause no specific troubles as far as it is used only a short

time (3 ~5 hrs.).

Even if the solvent contacts the floater when any accident takes place, it will not affect

the functional performance of the floater. For improving weatherproofing property, the

floater has a shade attached on.

(b) Cable

Cabtyre cable, which uses synthetic rubber as sheath material and polyethylene as

insulation respectively, is used.

5-2. Transducer

Apolarm-C is composed of detector and transducer, and is made in an intrinsic safety

explosion-proof structure.

(1) Kinds of transducer Table 5-3

Models Specifications Circuit

Fig.

External

shape Fig

AS-40E

Examination

Passage No.

C14649

Intrinsic safety explosion- proof structure,

Ex [ia]ⅡC Equipped with delay circuit,

wire disconnection alarm and short-circuit

alarm.

For installation in non- hazardous place

and inside of buildings.

Fig. 5-1 Fig. 5-2

9

(2) Restriction on wiring length

The cable that connects detector and transducer works as a kind of condenser and coil.

Electric energy may accumulate in this cable and such energy may work to impair the

intrinsic safety of the device. For this reason, the maximum wiring cable length is

restricted under the explosion-proofing principles.

Table 5-4

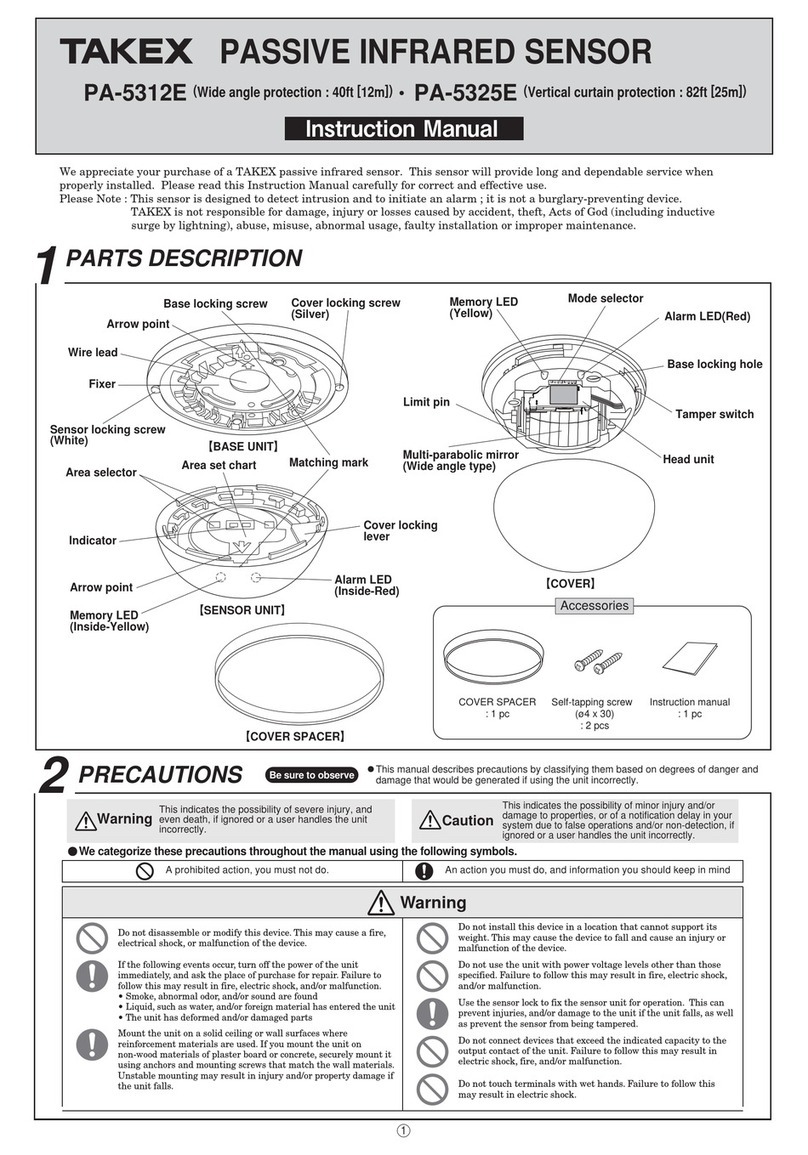

Fig. 5-1 AS-40E

RY1

RY2

LD2 RY1 RY2

LD1

VR

P

N

E

ZD

F

(AS-30)

◎ Explosion-proof structure

Intrinsic safety explosion-proof structure (explosion-proof mark Ex [ia] ⅡCT4)

◎Rating

Intrinsic safety circuit

DC16mA, 12V

Short-circuit current DC12l.6mA (max)

Open-circuit voltage DC14.3V (max)

Non-intrinsic safety circuit

1. Input power source voltage

AC 100~110V±10% 50/60Hz

AC 200~220V±10% 50/60HZ

2. Contact capacity AC 250 V, 4A DC30V, 4A

3. Control contact circuit 2C

(Oil leakage, system trouble)

4. Ambient temperature and humidity for working -10 ~ +50℃≦95%RH

5. Pilot lamp Green: oil leakage

Red: system trouble

Models Explosion-proofing

grade Use conditions

Wiring length for

reference; 600V CVV

2mm core (2)

AS-40E Ex [ia] ⅡCT4 Allowable inductance

L: smaller than2mH

Allowable capacitance

C : smaller than 0.5μF

For safety's sake, it is

desirable to restrict the

length within2 km.

10

◎Specifications

1. Working (current)

Oil detects: normal condition

About 10mA ~20mA Ry1 OFF

Oil leakage

About 3mA ~8mA Ry1 ON

System trouble: wire disconnection

≦2 mA Ry2 OFF

Short circuit

≧21 mA Ry2 OFF

2. Length of cable usable

2km at max with 2 mm core cable

3. Power consumption

2 VA with rated voltage

(Model CSR-3005E)

4. Delay time 1~10 sec (adjustable)

Fig. 5-2 Dimensions of Transducer

N2 P2

C1 B1 A1 C2 B2 A2 0V 110V

~

100V

220V

200V

~

E1

E2

N1 P1ENP

5

0

10

SYSTEM ALARM

OIL ALARM DeIay Time(sec)

5 8 15.2 19167213

25

14

80

110

5141615.2

14

25

80

120

4-2.5R

Outer terminal

Power source terminal

Intrinsic safety circuit side terminal holder 3P

Pilotlamp (Green) Oil ALARM

Pilotlamp (Red) System ALARM

G

11

5-3. Dry pit attachment

In case there is no water ordinarily or there is a fear of water being emptied, dry pit

attachment is used. When the water level drops, the electrode points come in contact with the

contact plate of the attachment and cease to further go down.

Therefore, the electrodes are earthed as are when floating on water.

(1) For visual figure, see Fig. 5-3.

Fig. 5-3 External figure of dry pit attachment Model TC-SE

①Set screw (4 mm)

②Pipe. 10ASUS 304

Sch #80 (JIS)

③265-1.6t SUS 304 plate

Note 1) Weight of dry pit attachment 1.5 kg

Note 2) Supporter rods should be prepared on the side of client. The inner diameter of pipe for

leg section is 10.9 mmφ. As supporter rod, pipe with an outer diameter of 10.5mmφ

or 10 mmφis recommendable.

1.6t

Set screw(4mm)

92

12

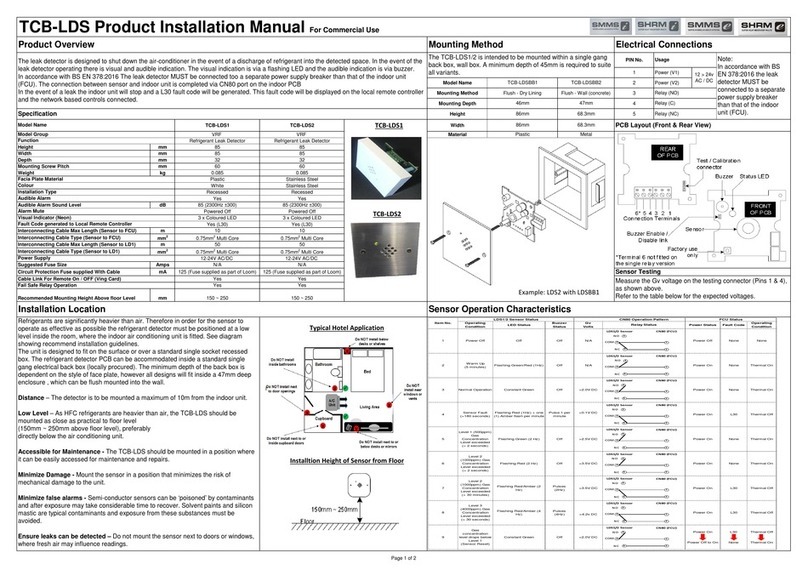

6-1. Wire connection diagram

"Apolarm-C" can function in 2-combined state of 1. Detector (Model CSR-3005E) and

2.Transducer (Model AS- 40E)

In connecting Apolarm-C and transducer, do it correctly in accordance with Fig.6-1

Note: As regards intrinsic safety terminals PN between detector and transducer, connect the

white color cable attached to detector to P and the black color cable to N.

If it connected reversibly by mistake, the device gives out oil leakage detection signal

though device breakdown cannot take place because of it.

6-2. Operation

Upon finish of equipment installation and wiring, go through the following preparatory steps

for operation.

(1) Check the wiring to confirm there are no misconnections of cable.

(2) Confirm that Apolarm-C correctly floats on water surface or is correctly held on dry pit

attachment. (Confirmation of absence of oil there)

(3) Confirm that power source is in the specified state.

Fig. 6-1 Wiring

Wirin

g

and o

p

eration

G

220V

200~

110V

100~

E

N

P

A2

C2

A1

C1

OV

B2

B1

E1

N1

P1

E2

N2

P2

110V

100~

220V

200~

OV

A2

C2

A1

C1

B2

B1

NP

P

N

E

APLARM-C

White

Black

(inside view)

Transducer

Oil

Leakage

Sysytem

trouble

Power

input

Ground

G

G

Model : CSR-3005E

Model:AS-40E

13

(4) Operation

Table 6-1

Normal Oil detect

System trouble

(APOLARM Cable

short or open)

APOLARM-C

Model

CSR-3005E

Pilot Lamp

(Green) ON OFF OFF

Pilot Lamp

(Green) ON OFF ON

Lamp

Transducer

Model AS-40E Pilot Lamp

(Red) OFF OFF ON

Oil ALARM

Contact A1-C1 OPEN CLOSE OPEN

Oil ALARM

Contact B1-C1 CLOSE OPEN CLOSE

System ALARM

Contact A2-C2 CLOSE CLOSE OPEN

Contact Transducer

Model AS-40E

System ALARM

Contact B2-C2 OPEN OPEN CLOSE

6-3. Oil leakage detection test

Detecting sensitivity of Apolarm-C is tested along the following steps.

(1) Prepare a test-use water tank and put water in it.

Put Apolarm-C on the water surface.

In case of metallic water tank, it should be larger 400 mmφand in case of plastic water

tank, it should be larger than 350 mmφ. Earth the water in tank.

(2) Make correct wiring for Apolarm-C and its transducer. (See Fig.6-1)

(3) Hold the cable of Apolarm-C at right above the detector. (Standard length of cable for this

holding is 1 m.)

(4) Put ON the power source of transducer.

(Pilot lamp green lights)

(5) Gently send oil falling on the water little by little from a comer the tank.

When the pilot lamp of transducer goes out, stop the oil sending.

Confirm the amount of oil fed in the tank.

(6) The oil layer thickness detectable is sought by the following formula.

H: Oil layer thickness (cm)

V: Amount of oil fed in tank (cm)

A: Surface area of water in tank (cm)

a: Cross section area of Apolarm-C on its draft line level

V

H =

A - a

14

7-1. Determination of place for installation

The thickness of oil layer produced by leaked oil gets the thinner the wider the dispersed area

of the oil. Therefore, it is important how to gather the leaked oil in a limited area.

Gathering of oil in a small area makes easier the work of oil recovering, which leads to

thwarting the mishap from expanding further. This eventually helps increase the reliability

of the detector.

Users are requested to understand enough the above fact and install Apolarm-C correctly at

an adequate place.

For example, such places as listed below are recommendable as places where to install

Apolarm-C.

a) Oil pit inside of the oil bank.

b) Oil pit in pump yard.

In case no water is held in the pit, use dry pit attachment.

c) Oil-separating tank located inside of a plant

d) Oil-separating tank for gas1 station.

e) Inlet and outlet of wastewater treating plants.

f) Oil pit in piers.

g) Oil-separating tank in drainage for plants.

7-2. Effective installation method

a) An installation example inside of tank yard and pump yard.

In tank yard, there is a drain valve attached and accordingly water can be emptied even from

its oil separation pit.

For this reason, dry pit attachment has to be installed there.

①

②

③

④

⑤

⑥

⑦

⑧

①Oil tank ②Oil separation pit

③Oil bank ④Valve

⑤APOLARM-C ⑥Dry pit attachment

⑦Apolarm guide ⑧Junction box

Installation of A

p

olarm-C

15

b) An installation example in oil separation pit

①As generally the oil separation pit is filled with water.

Therefore, it is unnecessary to set dry pit attachment there.

When the oil pit is emptied, warning signal is send forth.

②If there is any obstacle in oil separation pit or if there is a fear of something getting near

the waste water inlet, set there the Apolarm guide.

c) An installation example of Apolarm guide.

Junction box

A

POLARM-C

Oil separation pit

■Oil separation pit

Dry pit attachment

A

polam guide

■Dry pit

Guide

Ball float

■In case variation of water level is large

16

d) An installation example in large capacity pit (excessively large pit).

In case of large capacities pit that usually holds water in it; prepare a detecting-use

separator as shown in the bellow figure.

The appropriate length & width measurements of separator is ordinarily 400 ~ 600 mm.

Separator

Separator

A

polarm

17

7-3. Cautions for installation work

(1) Relation between oil layer thickness detectable and out flowing amount of oil

The amount the leaked-out oil is required to reach after oil begins to leak out for the

detector to start giving out oil detection signal is indicated by the following formula:

Amount of leaked-out oil

= (oil layer thickness detectable by detector) ×(surface area of pit)

Particularly when the detector is installed in an oil-water separation tank or wastewater

pit with a large surface area, it is required to divide the tank room with oil separator, or to

take a similar measure.

Such care eventually insures better sensing effect of the detector.

(2) High viscosity oil

With its out-protruded electrodes,

Apolarm-C readily detects presence of high viscosity oil.

Even if the oil has got greasy, it can be detected if the oil gathers around the detector.

Therefore, it is unnecessary to take a specific measure to detect high viscosity oil.

(3) Freezing

Even if the inside of pit has completely got in a frozen state, this freezing does not cause

Apolarm-C to be damaged.

However, in such a state, the detector cannot sense the presence of oil until the water is

not frozen.

Therefore, the pit must be kept from freezing inside.

To mention precisely, the measure to take for prevention of freezing should differ

according to the place Apolarm is installed.

But a typical method to keep the pit safe from freezing is providing a heating source

inside of the pit. In this case, give consideration not to raise the temperature of water over

60℃.

(4) Floating matters

Apolarm-C is perfectly free from the adverse effects of dust floating on water surface,

organisms, slime, duckweed, scale, etc. contained in water.

However, a large volume of dust can hinder in-flowing oil.

Therefore, dust has to be removed from water surface periodically.

(5) Wave and flow rate of water

Apolarm-C is unsymmetrical between its upper section and lower section, which works to

quickly stabilize its posture against up-and-down motion of waves.

As long as any of the three electrodes is in touch with water, Apolarm continues to give

out normal signal.

While the probability of all of three electrodes going out of touch with water surface at the

same time is very small, the transducer is provided with a delay circuit of approximately 1

~1 0 second.

Because of these factors, users need no fear signaling errors attributable to water waves.

As to water flow rate, keep it within 0.2m/sec. on the flowing water surface.

If the flow rate is larger than this limit, the oil layer could not maintain thickness of 3~

5mm or more.

In any case, don't forget providing guide rods.

18

(6) Correlation between thickness of detected oil layer and cable load

The weight of cable is 100g/m. Floater is so adjusted as to detect a 4mm thick layer of

kerosine under a load of 1 m long cable.

Detected oil layer thickness is in proportion to the sinking depth of electrodes.

Accordingly, with increased load of cable given on floater, the detected oil layer depty

increases.

In case floater swings sideways, these swings likewise influence the oil layer depty at

which the presence of oil is detected.

Therefore, where water waves regularly cause large lateral swings of floater; some

appropriate measure to offset such influence has to be taken.

As such measure, the following two" " methods are conceivable:

1) To make smaller the head of inflowing wastewater or to scatter the in-flowing course of

the water.

2) To make smaller the waves at the location of detector by placing their wave-breaking

plate, net, chamber, etc.

(7) Noise proof structure

A high frequency (around 1 MHz) is used inside this detector, which, therefore, may issue

false signal if a transceiver or other high frequency source is nearby.

Though this new Apolarm (CSR-3005E) has enhanced its immunity against external

interference, do not use, as much as possible, such a transceiver, etc. near the Apolarm.

If it is not allowed to keep a sufficient distance from the noise source, design the

installation rack and cables of the Apolarm-C into a shielded structure.

19

Fig.8-1 below “recommended wiring” shows a general outline of Apolarm-C wiring. For details,

please see ”User’s Guide for the Installation of Explosion-proof Electrical Equipment” Here is

excerpts form the guideline which will help customer install Apolarm-C wiring.

8-1. Selection of installation site

Before wiring, customer should select an installation site for Apolarm-C. Then based on

the section 5.5 ”Type of hazardous area and its scope “ of the “Guidelines for the

Installation of Explosion-proofed Electrical Equipment”, customer should clearly know

the hazardous grade of the selected site (Ex. Class 0,Class 1,Class 2 hazardous area),

and clarify the grade of wiring work required as well (Ex. intrinsic safety wiring etc.)

(In class 0 hazardous area, only intrinsic safety-type electrical equipment with

explosion-proof structure can be installed.)

How to install Ex

p

losion-

p

roof wirin

g

Table of contents

Popular Security Sensor manuals by other brands

Takex

Takex PA-5312E instruction manual

Toshiba

Toshiba TCB-LDS Series installation manual

Jula

Jula 400-235 operating instructions

B.E.G.

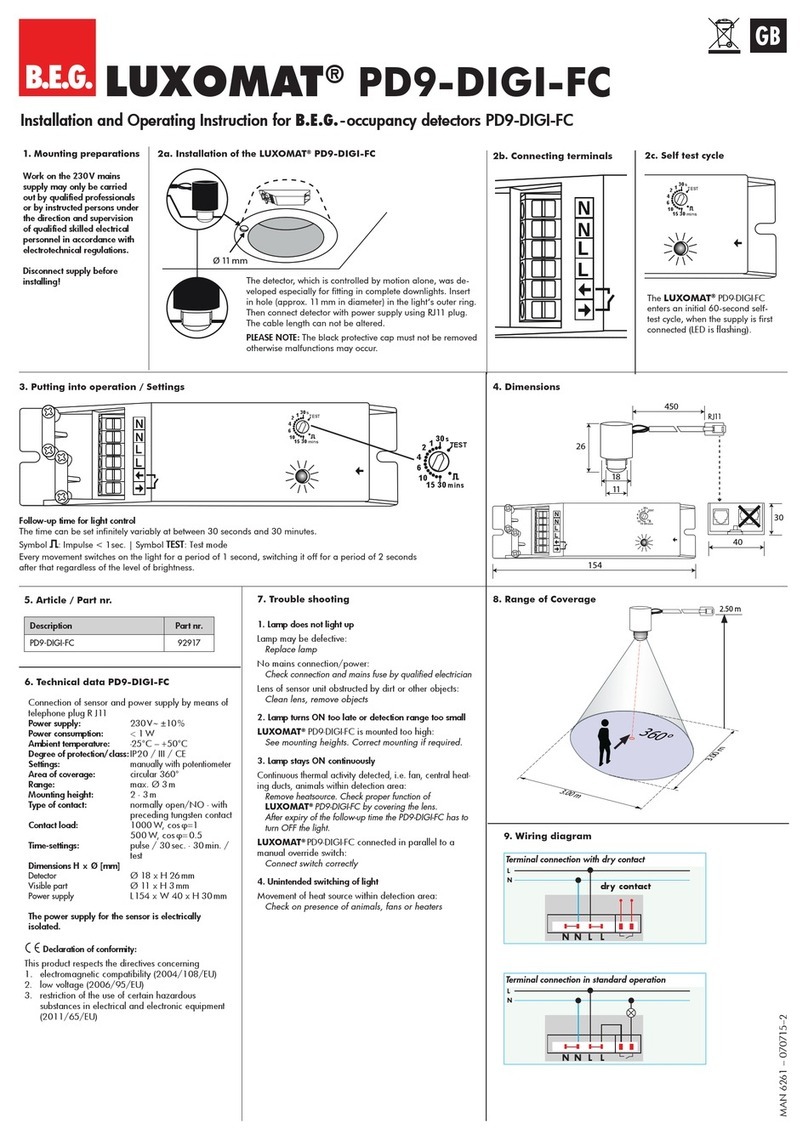

B.E.G. LUXOMAT PD9-DIGI-FC Installation and operating instruction

ITALIANA SENSORI

ITALIANA SENSORI 8032-ISR023 Installation, operation and maintenance manual

Omron

Omron Z302-E1-03 user manual

Hansen Technologies

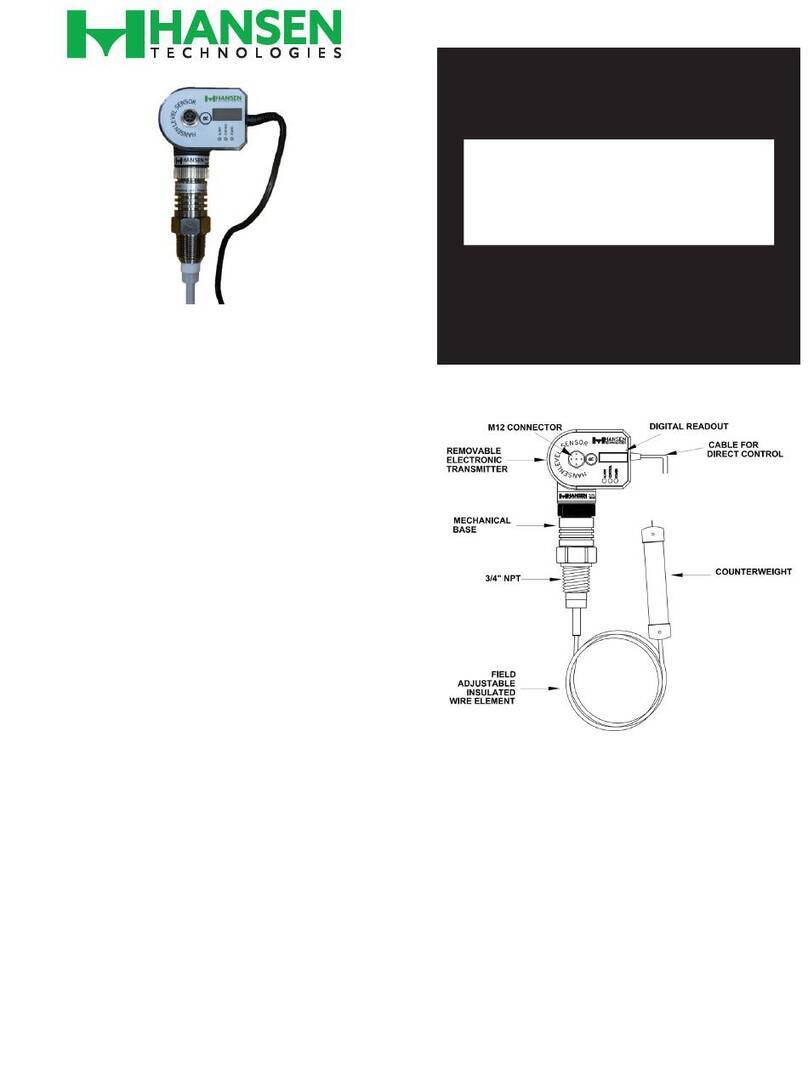

Hansen Technologies WLT Specifications, Applications, Service Instructions & Parts

METREL

METREL MD116 operating instructions

green-i

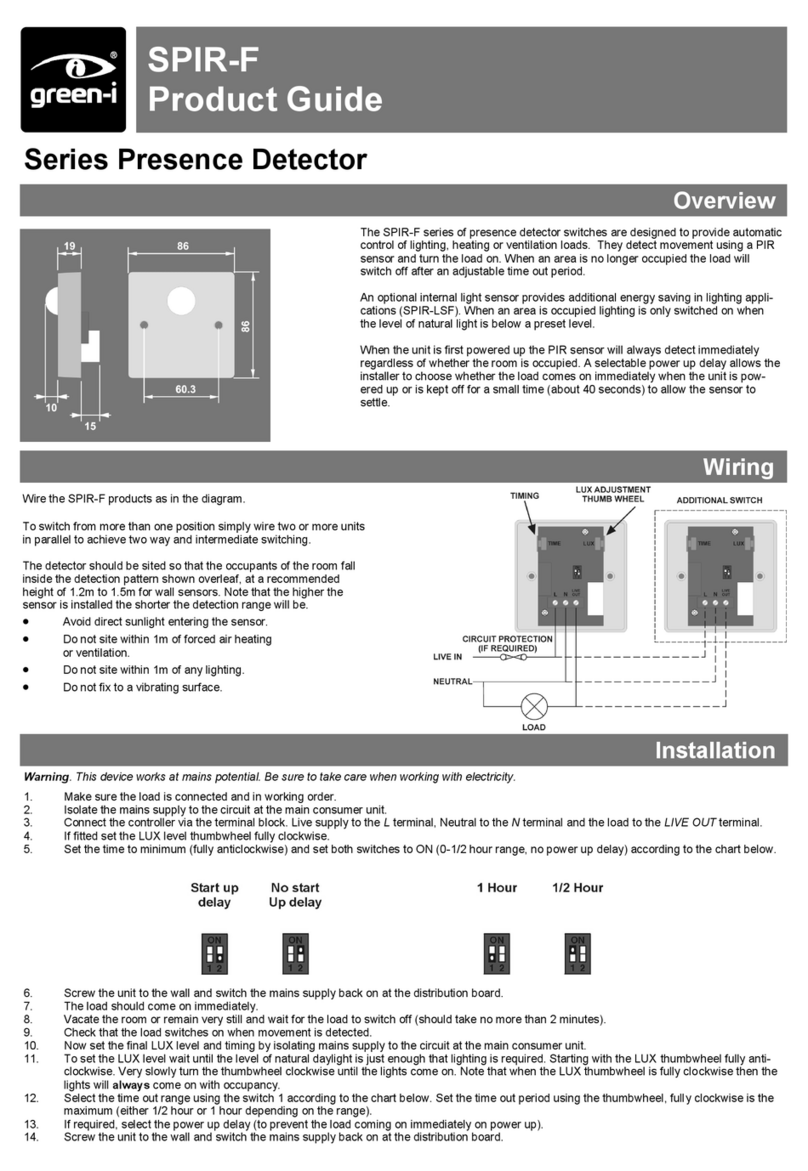

green-i SPIR-F Product guide

Feig Electronic

Feig Electronic VEK M1H operating instructions

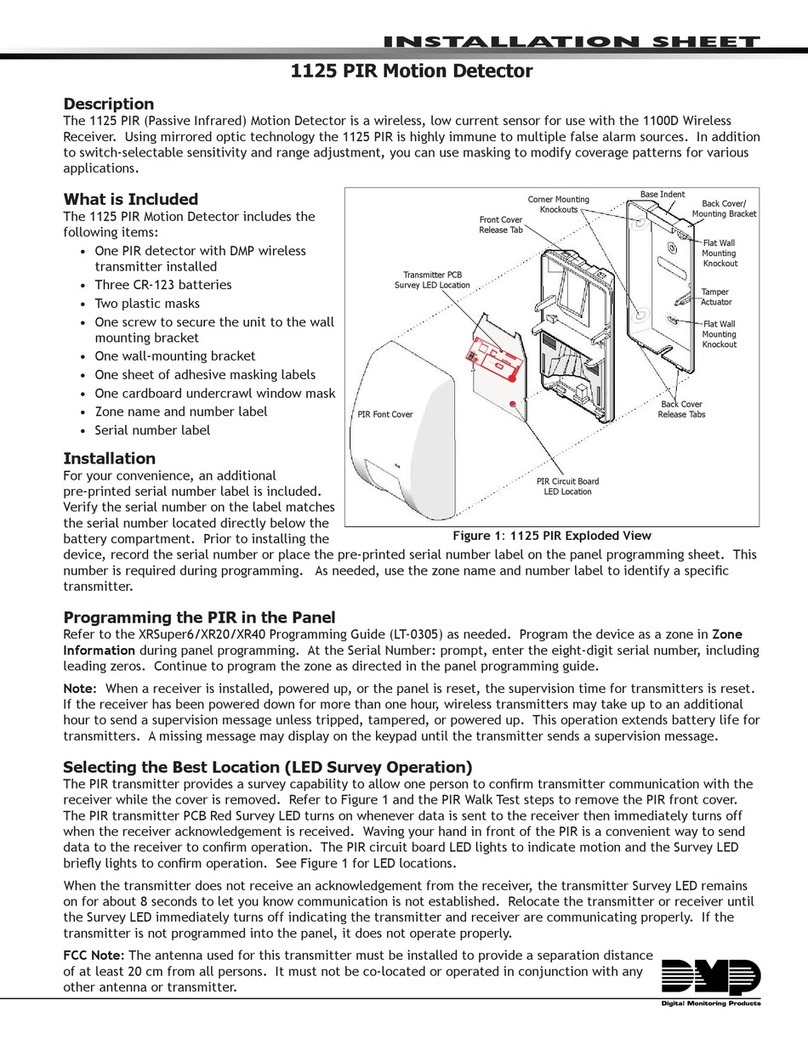

DMP Electronics

DMP Electronics 1125 Installation sheet

Vive

Vive LVA1074BED user manual