MANUAL [PY740025/26]•Subject to alteration! Version: 22.10.2018

ipf electronic gmbh

• Kalver Straße 25 - 27 • 58515 Lüdenscheid

│

Tel +49 2351 9365-0 • Fax +49 2351 9365-19

│

info@ipf.de • www.ipf.de 2

Contents

1General information......................................................................................................................3

1.1 Concerning the contents of this document .....................................................................................3

1.2 Intended use ...................................................................................................................................3

1.3 Safety warnings ..............................................................................................................................3

2Commissioning.............................................................................................................................4

3Connection ....................................................................................................................................8

3.1 Connection cable ............................................................................................................................8

3.2 Pin assignment and connection diagram........................................................................................9

4Installation ...................................................................................................................................10

4.1 Mounting .......................................................................................................................................10

4.2 Sensor reference levels ................................................................................................................10

4.3 The reference surface................................................................................................................... 11

4.4Measuring field defintion...............................................................................................................12

4.5 Mounting .......................................................................................................................................14

4.6 Installation accessories.................................................................................................................16

5Configuration ..............................................................................................................................17

5.1 Overview of control elements .......................................................................................................17

5.2 Function tree .................................................................................................................................20

5.3 LIVE MONITOR ............................................................................................................................21

5.4 MESSTYP.....................................................................................................................................24

5.5 FLEX MOUNT (Function HEIGHT)...............................................................................................25

5.6 OBJECT........................................................................................................................................30

5.7 PRECISION ..................................................................................................................................30

5.8 FIELD OF VIEW ...........................................................................................................................33

5.9 ANALOG OUT ..............................................................................................................................35

5.10 DIGITAL OUT................................................................................................................................37

5.11 SYSTEM .......................................................................................................................................39

5.12 SETTING ......................................................................................................................................41

6Function and definition ..............................................................................................................42

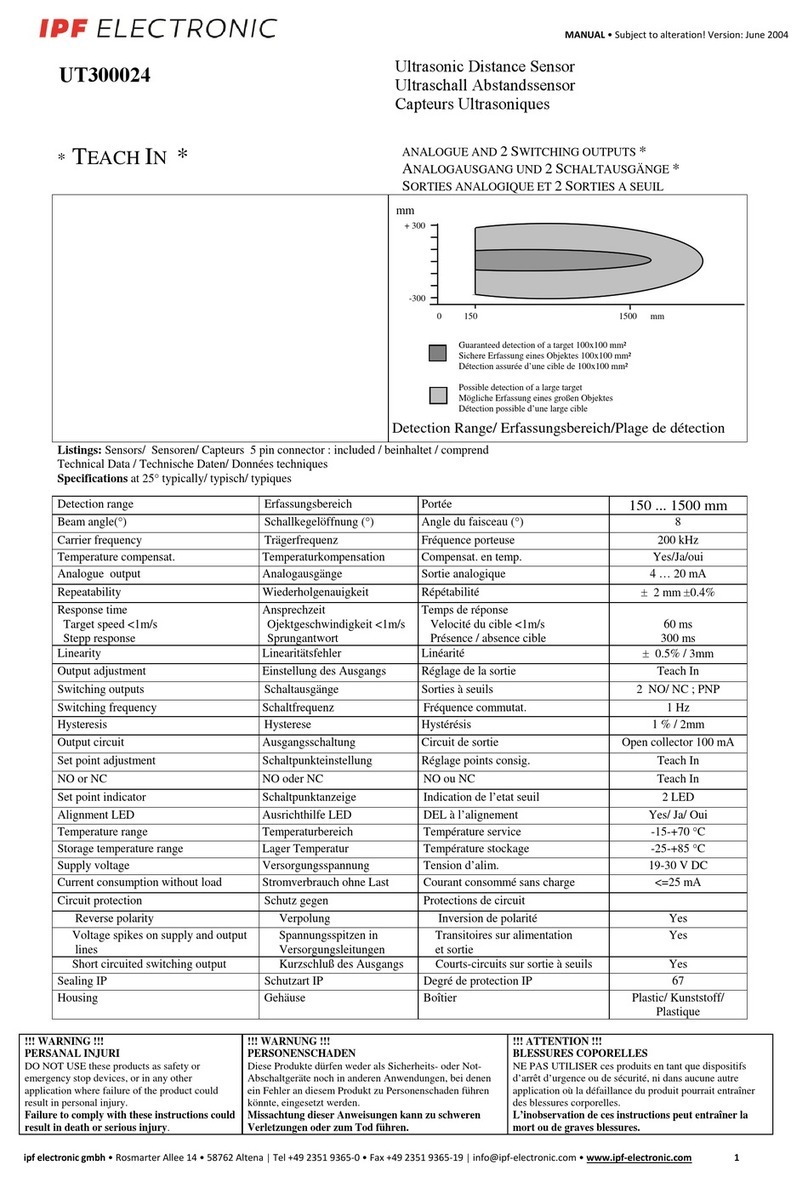

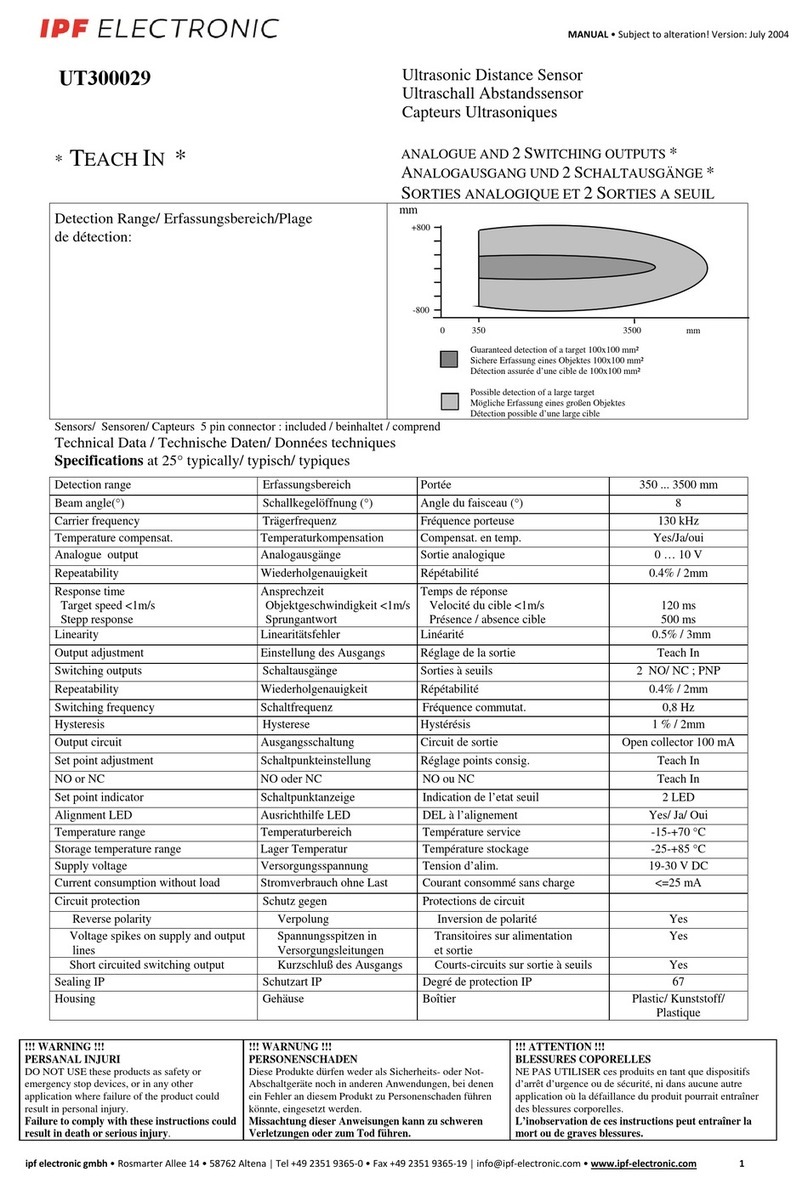

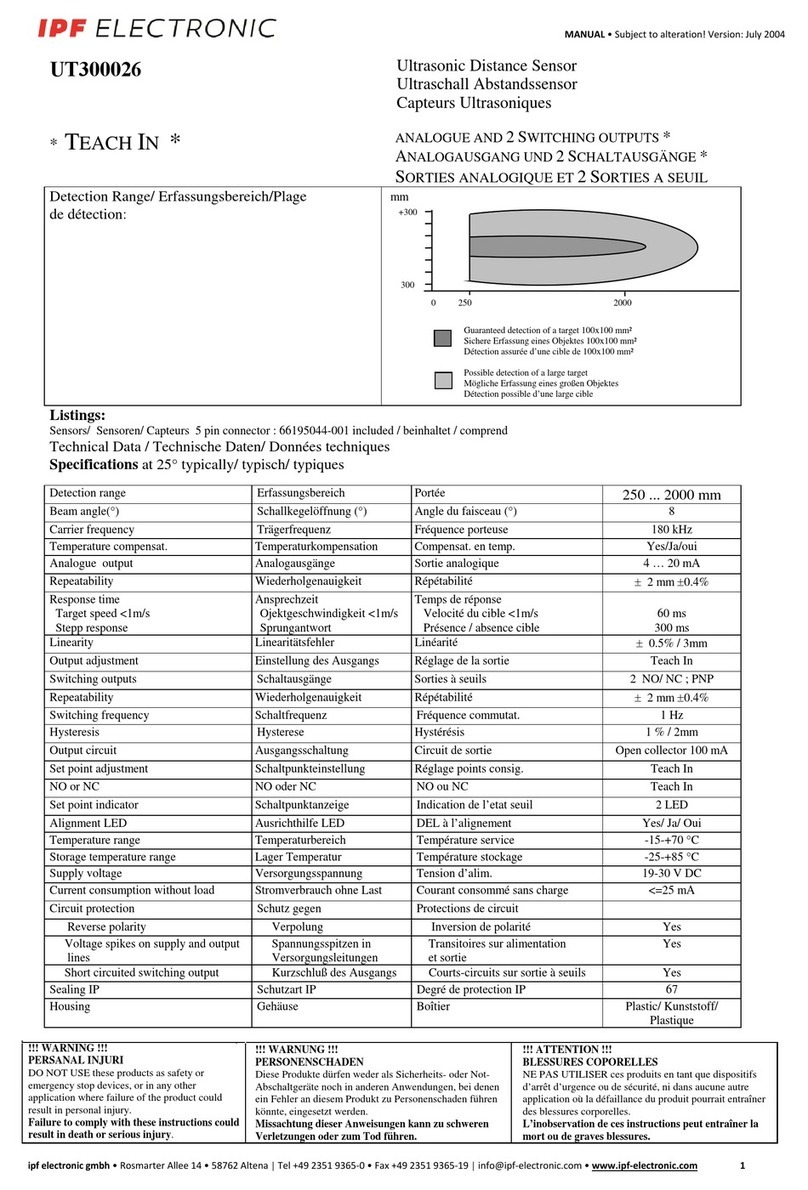

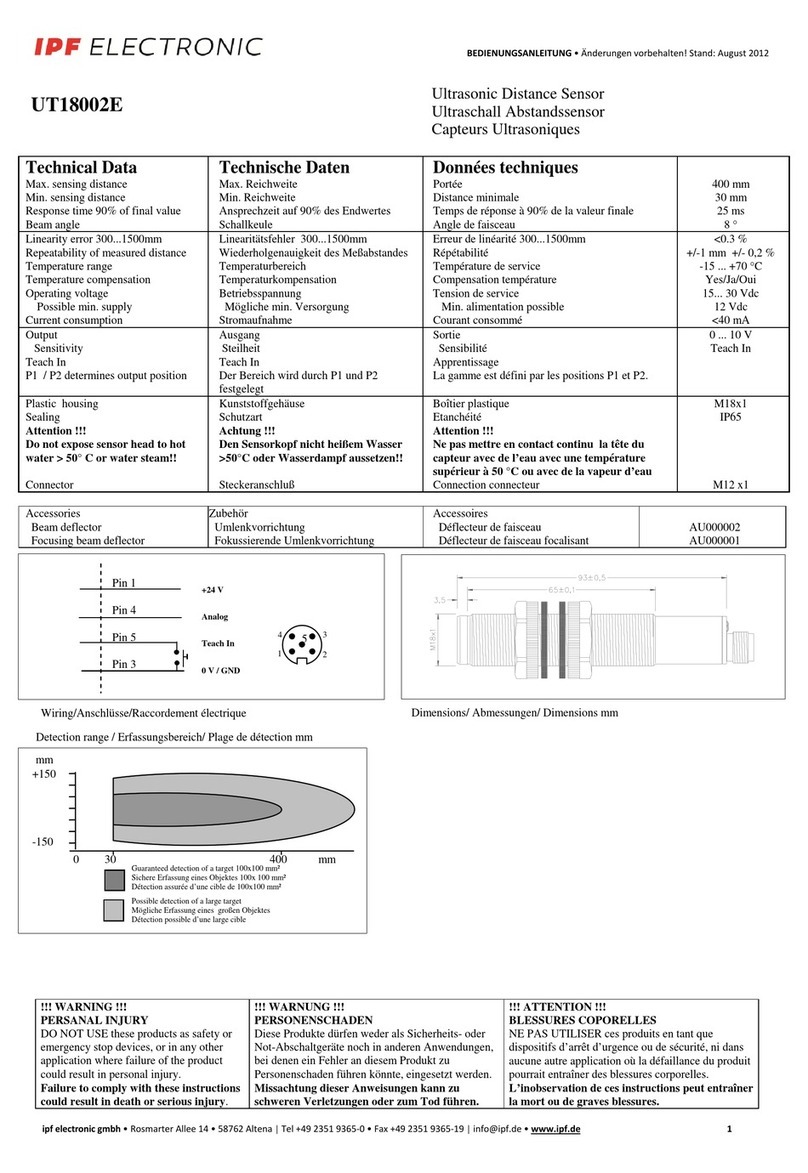

6.1 Sensors data sheet.......................................................................................................................42

6.2 Functional principle.......................................................................................................................47

6.3 Measuring repetition time and response time...............................................................................49

6.4 Hysteresis .....................................................................................................................................50

6.5 Object to be measured .................................................................................................................52

6.6Interfaces and outputs ..................................................................................................................53

6.6 Touch panel...................................................................................................................................61

6.7 Memory .........................................................................................................................................61

6.8 Standard deviation........................................................................................................................62

7Safety instructions and maintenance.......................................................................................63

7.1 General safety instructions ...........................................................................................................63

7.2 Part identification ..........................................................................................................................63

7.3 Influence of ambient light..............................................................................................................65

7.4 Front (optics).................................................................................................................................65

7.5 Cleaning the sensors ....................................................................................................................65

7.6 Disposal ........................................................................................................................................65

8Error correction and tips............................................................................................................66

8.1 Examples of sensor setup ............................................................................................................66

8.2 Error correction .............................................................................................................................67