Installation, Operation and Maintenance Manual

【H-V028-E-20】Diaphragm Valves Type 14 (True Union Diaphragm Valves Type14) 2

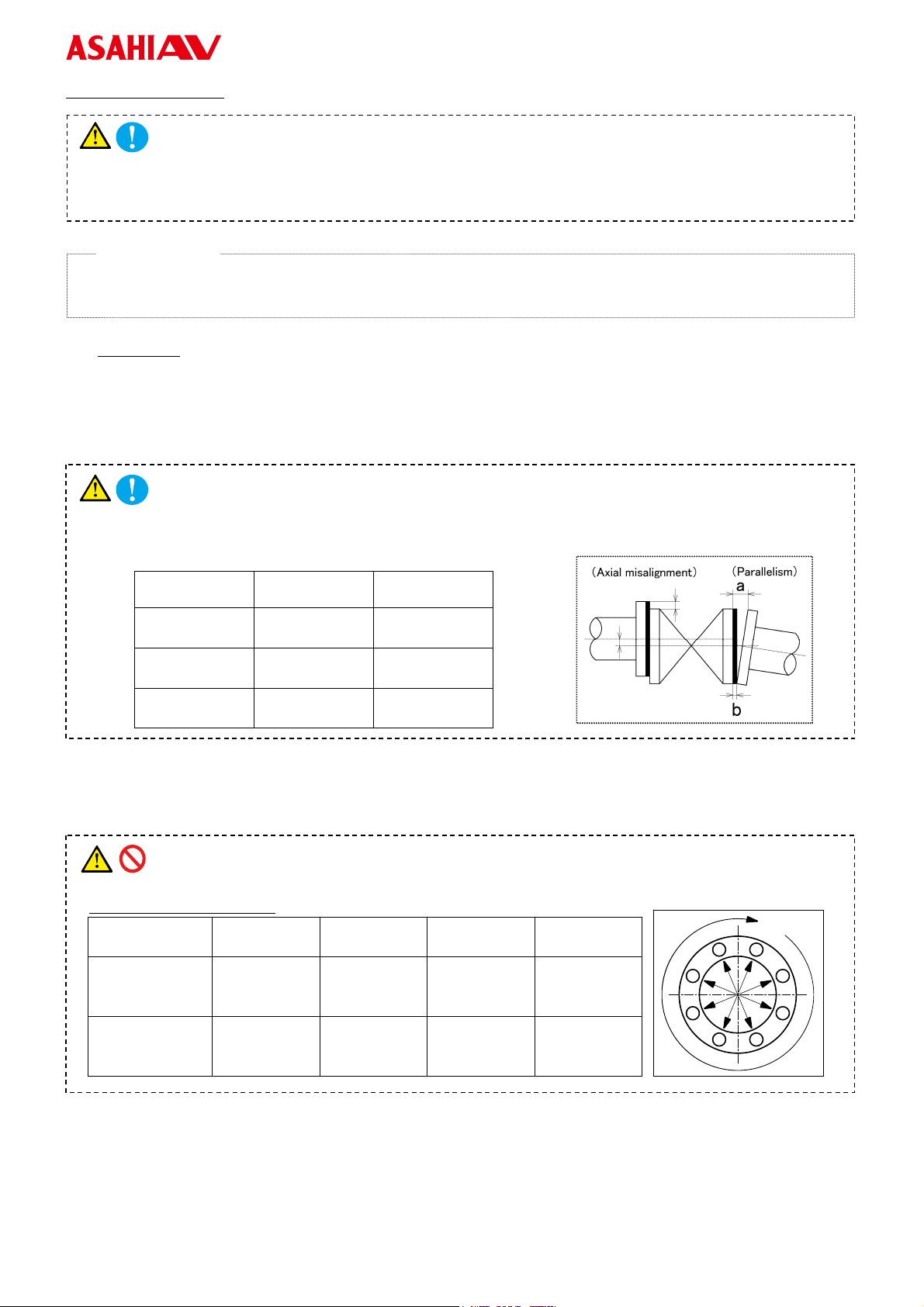

(2) General operating instructions

- Using a positive-pressure gas with our plastic piping may pose a dangerous condition due to the repellent force

particular to compressible fluids even when the gas is under similar pressures used for liquids. Therefore, be

sure to take the necessary safety precautions such as covering the piping with protective material. For

inquiries, please contact us. For conducting a leak test on newly installed piping, be sure to check for leaks

under water pressure. If absolutely necessary to use a gas in testing, please consult your nearest service

station beforehand.

- Do not step on or apply excessive weight on valve. (It can be damaged.)

- Do not use the valvein conditions where the fluid may have crystallized.

(The valve will not operate properly.)

- Keep the valve away from excessive heat orfire. (It can be damaged, or destroyed.)

-Always operate the valve within the pressure vs. temperature range.

(The valve can be damaged ordeformed by operating beyond the allowable range.)

-Allow sufficient space for maintenance and inspection.

- Select a valve material that is compatible with the media. For chemical resistance information, refer to

“CHEMICALRESISTANCE ONASAHIAV VALVE”.

(Some chemicals may damage incompatible valve materials.)

- Keep the valve out ofdirect sunlight, water and dust. Use cover to shield the valve.

(The valve will not operate properly.)

- Perform periodic maintenance. (Leakage may develop due to temperature changes or periods of prolonged

storage, rest, or operation.)

- Thetravel stop may have to be adjusted if media leakage is detected between the upstream & downstream

sides of the valve.

- Bonnet bolt torque should be checked before installation, as they may become loose after long-term storage.

-Aperiodic check ofthe valve condition as well as bonnet & flange bolt torque shouldbe made part of

preventative maintenance program properly re-tightening the bolts as necessary.

It is especially important to re-tighten all bolts during the first shutdown.

(3) General instructions for transportation, unpacking and storage

- When suspending and supporting a valve, takecare and do not stand under a suspended valve.

- This valve is not designed to handle impacts of any kind. Avoid throwing or dropping the valve.

-Avoid scratching the valve with any sharp object.

- Do not over-stack cardboard shipping boxes. Excessively stacked packages may collapse.

-Avoid contact with any coal tar creosote, insecticides, vermicides or paint.

(These chemicals may cause damage to the valve.)

- Store products in their corrugated cardboard boxes. Avoid exposing products to direct sunlight, and store

them indoors (at room temperature). Also avoid storing products in areas with excessive temperatures.

(Corrugated cardboard packages become weaker as they become wet with water or other liquid. Take care

in storage and handling.)

-After unpacking the products, check that they are defect-free and meet the specifications.

arning

Caution

arning

Caution