Serial No.: H-A079-E-00

[User’s Manual] Butterfly valve Type 58 Pneumatic Actuated Type FL 700mm (28”) ~900mm (36”)

- 3 -

Table of contents

1. Our product warranty coverage···························································································4

Applicable to .......................................................................................................................................................................... 4

Warranty Period..................................................................................................................................................................... 4

Guaranteed range ................................................................................................................................................................. 4

Disclaimer............................................................................................................................................................................... 4

2. Safety Instructions················································································································5

Unpacking, Transportation and Storage .......................................................................................................................... 5

Product Handling .................................................................................................................................................................. 6

3. Name of each part·················································································································8

4. Product Specifications ·········································································································8

Product model code list ....................................................................................................................................................... 8

Relationship between maximum allowable pressure and temperature .................................................................... 9

Actuator................................................................................................................................................................................... 9

Standard option..................................................................................................................................................................... 9

Solenoid Valve Specification ............................................................................................................................................ 10

Filter regulator specifications........................................................................................................................................... 11

Speed controller specifications........................................................................................................................................ 11

Limit switch box specifications........................................................................................................................................ 12

5. Piping method······················································································································13

Wafer shape ......................................................................................................................................................................... 13

Product support................................................................................................................................................................... 18

6. Air piping method················································································································19

7. How to Connect Options ····································································································21

Limit switch.......................................................................................................................................................................... 21

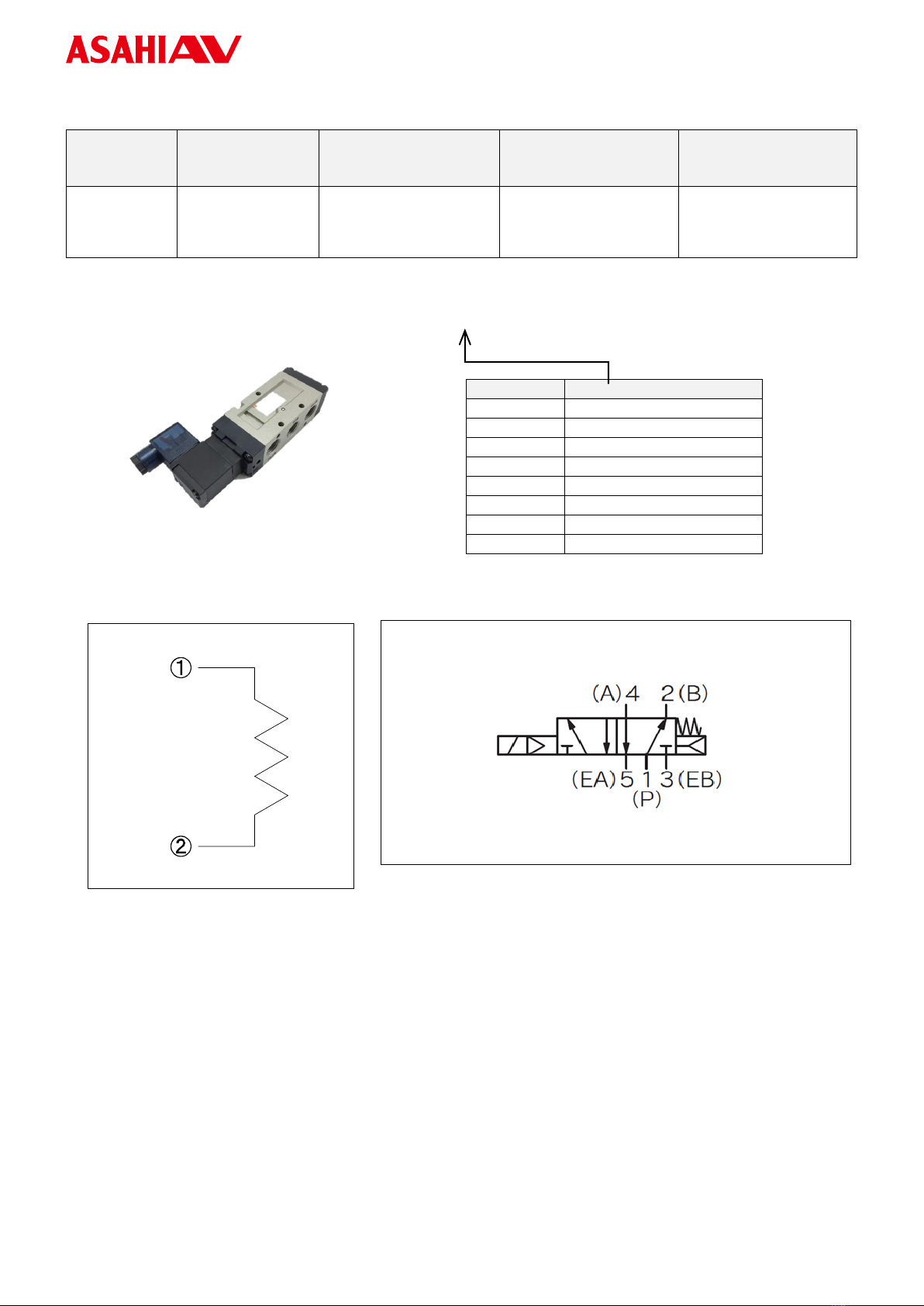

Solenoid valve...................................................................................................................................................................... 22

8. Manual operation ················································································································23

Manual operation................................................................................................................................................................ 23

9. Air Operation························································································································25

10. How to adjust the stopper································································································26

11. How to adjust open/close speed ····················································································27

12. Inspection item··················································································································28

Daily inspection................................................................................................................................................................... 28

Periodic inspection ............................................................................................................................................................. 29

13. Troubleshooting ················································································································31

14. How to inquire about defects or replacement·······························································34