Ascension VIRTUOSO 5460P Series Operating instructions

MAINTENANCE & REPAIR

MANUAL

Patented – see www.wheelchairlift.com/patents

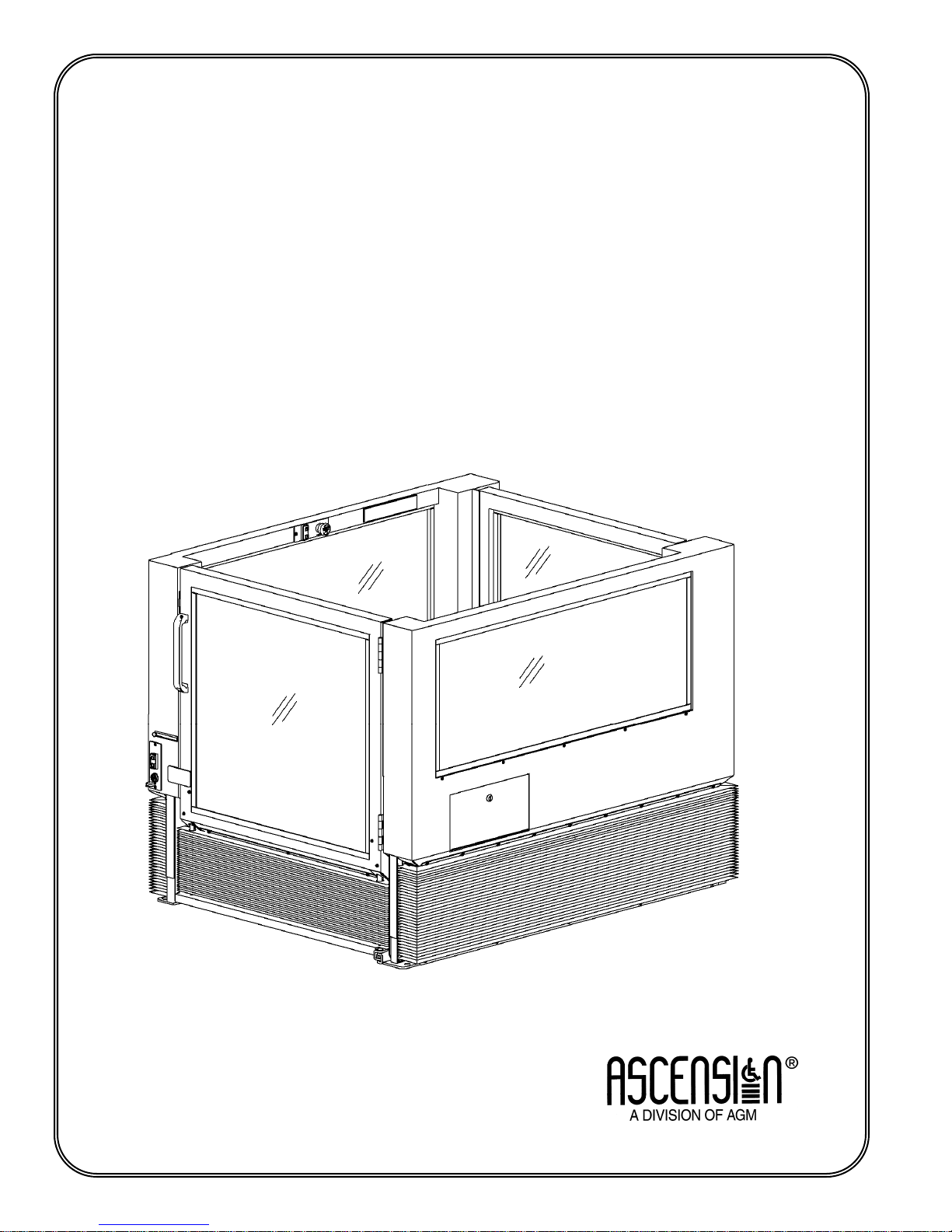

ASCENSION VIRTUOSO

PORTABLE WHEELCHAIR LIFT

5460P MODEL SERIES

ASCENSION VIRTUOSO

PORTABLE WHEELCHAIR LIFT

5460P MODEL SERIES

MAINTENANCE & REPAIR

MANUAL

Copyright © 2014 Ascension, A Division of AGM, Tucson, Arizona

This document, or parts thereof, may not be reproduced in any form, by any method, for

any purpose, without written permission of Ascension.

TABLE OF CONTENTS

INTRODUCTION.............................................................................................................1

About This Manual.......................................................................................................1

Additional Information..................................................................................................2

Getting Help.................................................................................................................2

Contacting Ascension..................................................................................................2

SECTION 1: Terminology...............................................................................................3

SECTION 2: Routine Maintenance.................................................................................5

2.1 Hydraulic System..............................................................................................5

2.2 Cleaning............................................................................................................5

SECTION 3: Mechanical Disassembly and Repair.........................................................6

3.1 Important Preliminary Information.....................................................................6

3.2 Electrically Isolating the Lift...............................................................................6

3.3 Opening the Machinery Cabinets from the Top.................................................8

3.4 Retracting, Removing, and Reinstalling the Safety Skirt...................................9

3.5 Lower Landing Gate Closer ............................................................................15

3.6 Upper Lock Rollers .........................................................................................16

3.7 Lower Lock Rollers .........................................................................................18

3.8 Upper Stop Mechanism ..................................................................................20

3.9 Lower Landing Gate Switch............................................................................22

3.10 Upper Landing Gate Switch............................................................................24

3.11 Locking Rod Switch ........................................................................................25

3.12 Operating Stations..........................................................................................26

3.13 Override Keyswitch.........................................................................................27

3.14 Hydraulic Valves.............................................................................................28

3.15 Windows .........................................................................................................30

3.16 Skirt Guard......................................................................................................30

SECTION 4: Electrical Testing.....................................................................................36

4.1 Access to the Electrical Panel.........................................................................38

4.2 Testing the Switches.......................................................................................39

4.3 Testing the Relay Module ...............................................................................41

4.4 Testing the Power Supply...............................................................................42

4.5 Testing the Power Relay.................................................................................43

SECTION 5: Lift Compression/Expansion....................................................................44

5.1 Compressing the Lift.......................................................................................45

5.2 Expanding the Lift...........................................................................................49

5.3 Verification of Operation .................................................................................55

SECTION 6: Troubleshooting.......................................................................................56

Maintenance & Repair Manual Introduction

VIRTUOSO 5460P

110057 REV K

1

INTRODUCTION

The purpose of this manual is to provide the necessary information to perform

maintenance and repairs on the Ascension VIRTUOSO portable wheelchair lift. This

manual is intended to be used by skilled technicians who have experience working on

electro-mechanical systems and devices. Furthermore, these personnel should be well-

versed in standard industrial safety practices and procedures. The appropriate sections

should be read through completely before any repairs are begun.

About This Manual

This manual is divided into six sections:

Section 1 defines terms that are used throughout the remainder of this manual.

Section 2 describes the recommended procedures for performing routine maintenance.

Section 3 covers mechanical repair. This includes component replacement, as well as

detailed procedures to disassemble, test, and reassemble major components.

Section 4 covers electrical testing.

Section 5 describes how to compress the lift so that it can be rolled through a narrow

doorway and then expanded again for normal use.

Section 6 is a troubleshooting guide. It provides information for locating and correcting

any problems with the lift.

Maintenance & Repair Manual Introduction

VIRTUOSO 5460P

110057 REV K

2

Additional Information

The following sources of information supplement this manual:

Operating Manual An Operating Manual is supplied with each lift and includes all the

necessary information to set up, break down, store, and transport the lift. It also

includes the general safety precautions that should be observed.

Setup and Operation DVD A short setup and operation DVD is supplied with each lift.

Getting Help

If you have a question or problem with the lift, please try to find the solution in this

manual. In particular, be sure to review the troubleshooting guide in Section 6. If you

are not able to resolve the problem, please contact Ascension as indicated below,

making sure that you have the serial number of your lift ready. The serial number can

be found on the data plate located inside the lift car on the upper left rail. Also, it is

recommended that you contact Ascension while in the immediate vicinity of your lift, as

this will reduce the time required to properly diagnose the problem.

Contacting Ascension

Ascension's business hours are 8 a.m. to 5 p.m. Mountain Standard Time, Monday

through Friday.

Telephone: 800-459-0400 Mailing Address: Ascension

Fax: 520-881-4983 Customer Service

Email: sales@wheelchairlift.com PO Box 40020

Tucson, AZ 85717-0020

Maintenance & Repair Manual SECTION 1

VIRTUOSO 5460P

110057 REV K

3

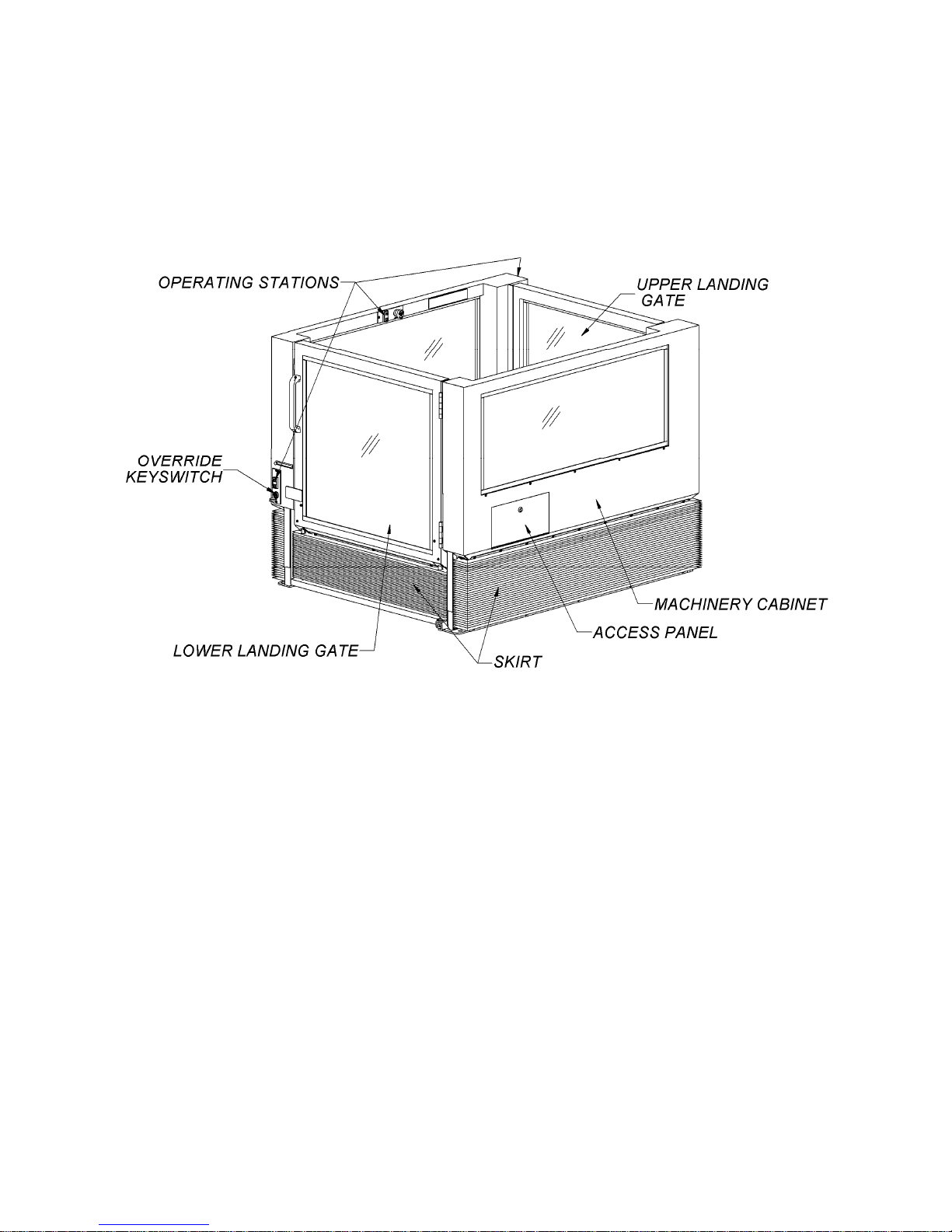

SECTION 1: Terminology

To effectively use this manual, you need to be familiar with the following terms. Refer to

the figure on the following page for identification of components. Not all components

are shown in the figure.

Access Panel The hinged panels (four total) that provide access to the machinery

cabinets.

Back End The end of the lift where the upper landing gate is located.

Base The steel frame that rests on the floor when the casters are removed and

supports the operating mechanism.

Control Panel The electrical panel for the lift which contains the power supply, control

system relay, and the main power relay. The control panel is located inside the left-

hand machinery cabinet.

Dock Plate The hinged plate that bridges the gap between the lift car floor and the

upper landing surface when the lift car is at the upper landing.

Front End The end of the lift where the lower landing gate is located.

Lift Car The compartment in which the passenger rides.

Lower Landing Gate The gate that serves the lower landing (ground level).

Machinery Cabinet The enclosures in which the lifting and control mechanisms are

located. There is one cabinet on each side of the lift. The contents of the machinery

cabinets are accessible through the access panels.

Operating Stations The controls for raising and lowering the lift car. All three

operating stations are located on the left side of the lift car. The operating station inside

the lift car has an emergency stop switch.

Override Keyswitch The switch used to operate the lift while installing or removing the

casters.

Skirt The accordion-style cover which completely encloses the underside of the lift car.

The skirt consists of two parts: the lift car skirt, which surrounds the lift car on three

sides; and the gate skirt, which protects the area under the lower landing gate.

Upper Landing The stage, platform, or riser that the lift serves.

Upper Landing Gate The gate that serves the upper landing, or stage.

Maintenance & Repair Manual SECTION 1

VIRTUOSO 5460P

110057 REV K

4

Maintenance & Repair Manual SECTION 2

VIRTUOSO 5460P

110057 REV K

5

SECTION 2: Routine Maintenance

2.1 Hydraulic System

The fluid level of the hydraulic system should be checked every six months. Before

checking the fluid level, make sure the lift car is at ground level (i.e., at the lower

landing) and off its casters. Then open one of the access panels in the right-hand

machinery cabinet and verify that the fluid level in the reservoir sight tube is between

the min-max marks on the reservoir.

Inspect the condition of the hydraulic fluid. Change the fluid if it has darkened, appears

dirty, or has a strong acrid or burnt odor.

If you need to add hydraulic fluid to the lift, use an ISO 32 grade hydraulic oil, such as

Texaco Rando HD32 or 76 Unax AW32 filtered to 10 microns for lifts primarily used

indoors. For outdoor lifts use a low-temperature oil such as Amsoil AWF oil. In order to

add fluid to the reservoir, pull the top of the flexible sight tube out of the access panel

opening, remove the bronze vent plug, and pour the hydraulic fluid into the sight tube.

2.2 Cleaning

All parts of the lift except the windows may be cleaned with soap and water or general

purpose household cleaners. Use a sponge or soft cloth dampened with cleaning

solution. Wipe dry with a cloth after cleaning. Do not expose any part of the lift to a

direct liquid stream or spray, such as from a water hose.

To clean the windows, Windex or Formula 409 brand window cleaners may be used.

To remove scratches, Plastic Polish 2 or 3 is recommended. Plastic Polish is available

from Novus, Inc, Minneapolis, Minnesota, item numbers PC-20 and PC-30 respectively.

Maintenance & Repair Manual SECTION 3

VIRTUOSO 5460P

6110057 REV K

SECTION 3: Mechanical Disassembly and Repair

3.1 Important Preliminary Information

The repairs in this section are to be performed by a skilled technician who has

experience working on electro-mechanical systems. Furthermore, the technician should

be well-versed in standard industrial safety practices and procedures. In the United

States of America, electrical safety procedures are established in OSHA's

Lockout/Tagout – Hazardous Energy Sources Standard (29 CFR 1920.147).

Familiarity with the setup and operation of the lift is required to effectively perform the

repairs listed in this section. This information can be found in the Operating Manual

provided with the lift.

3.2 Electrically Isolating the Lift

This section describes the procedures for electrically isolating the lift, which is

necessary in order to safely perform some of the repairs covered in this manual.

To electrically isolate the lift, perform the following steps in the order listed:

1. Remove the electrical plug from the wall outlet.

2. Attach a DANGER tag to the end of the electrical plug and lock out the plug

according to the procedures established in OSHA's Lockout/Tagout – Hazardous

Energy Sources Standard (29 CFR 1920.147).

3. Coil the electrical cord and place it inside the lift car. This will prevent the cord from

inadvertently being plugged in while repairs are underway.

4. Turn the lift off. The ON/OFF switch is located on the control panel located inside

the left-hand machinery cabinet.

To restore power to the lift, perform the following steps in the order listed:

1. Remove the lock from the electrical plug.

Maintenance & Repair Manual SECTION 3

VIRTUOSO 5460P

7110057 REV K

2. Plug the power cord into a wall outlet with 120 VAC power.

3. Press "Reset" on the GFCI if necessary.

4. Turn the lift on.

Maintenance & Repair Manual SECTION 3

VIRTUOSO 5460P

8110057 REV K

3.3 Opening the Machinery Cabinets from the Top

For some of the repairs described in this manual, it is necessary to gain access to a

machinery cabinet from the top. The top of either machinery cabinet can be removed

by performing the following steps:

1. Remove the window located above the machinery cabinet from its frame. See

Section 3.15.

2. Use a Phillips screwdriver to remove the ten (10) flat head screws which hold the

cabinet top in place. The top can now be removed from the cabinet. It may be

necessary to open an access panel and push from inside the cabinet to pop the top

out.

To reinstall the machinery cabinet top, perform the above steps in reverse order.

Maintenance & Repair Manual SECTION 3

VIRTUOSO 5460P

9110057 REV K

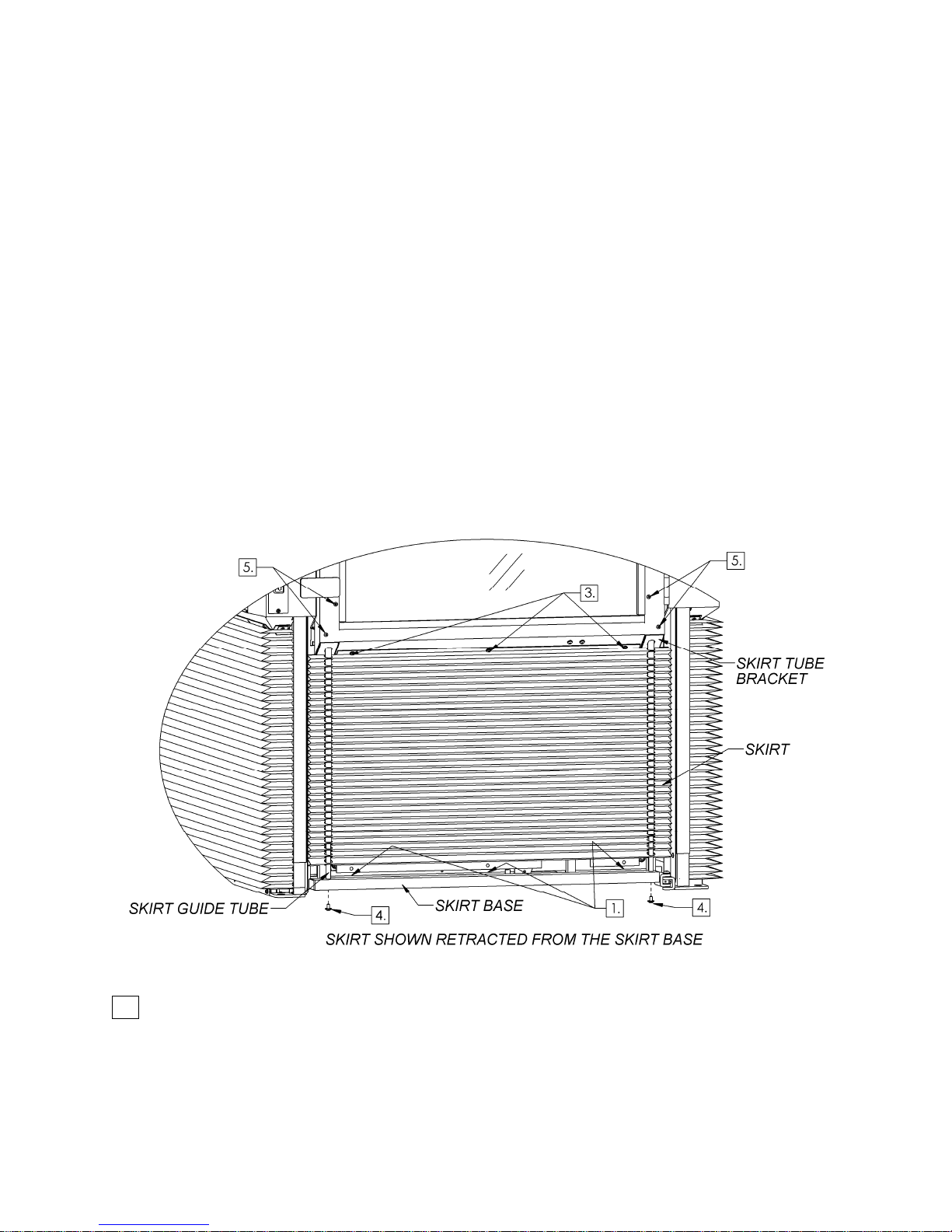

3.4 Retracting, Removing, and Reinstalling the Safety Skirt

The safety skirt consists of two parts: the lift car skirt, which guards the lift car on three

sides; and the gate skirt, which guards the area under the lower landing gate. For some

of the repairs described in this manual, it is necessary to gain access to components

normally hidden behind the skirt. In most cases, only a small portion of the skirt may

need to be retracted; however, sometimes it may be necessary to remove the whole

skirt.

To remove the gate skirt, perform all of the following steps. If the skirt only needs to be

retracted, performing only Step 3 will provide access to many of the components behind

the skirt. Refer to the figure below for the location of the fasteners referenced in each

step.

1. Use a 5/16" wrench to remove the three (3) hex head screws that secure the skirt

to the skirt base. These screws are located on the top side of the skirt base.

2. Using any operating station, raise the lift car until the car floor is approximately

24" off the ground.

Maintenance & Repair Manual SECTION 3

VIRTUOSO 5460P

10 110057 REV K

3. Use a Phillips screwdriver to remove the three (3) screws that secure the skirt to

the lower landing gate.

4. Use a 5/32" hex key to remove the two (2) button head cap screws and washers

that secure the skirt guide tubes to the skirt base. Hold the skirt guide tubes

stationary with pliers if necessary while removing the screws.

5. Use a Phillips screwdriver to remove the four (4) screws (two (2) on each side)

that secure the skirt guide tube brackets to the lower landing gate and pull the

brackets downward, out of the gate. The skirt can now be removed from the

gate.

To reinstall the gate skirt, perform the above steps in reverse order.

To remove the lift car skirt, perform all of the following steps. If the skirt only needs to

be retracted, performing only Steps 2 & 3 will provide access to most of the components

behind the skirt.

1. If the whole skirt is to be removed, raise or lower the lift car so that the lift car floor is

approximately 15" off the ground.

2. Use a Phillips screwdriver to remove the 28 pan head screws that secure the sides

of the skirt to the lift car at the top and to the lift base at the bottom.

3. Use a 5/16" combination wrench to remove the four (4) hex head screws that secure

the top of the skirt to the lift car, one (1) at each corner. Remove the small skirt

support brackets that are freed when these screws are removed.

4. Use a Phillips screwdriver to remove the pan head screw that secures the back of

the skirt to the base.

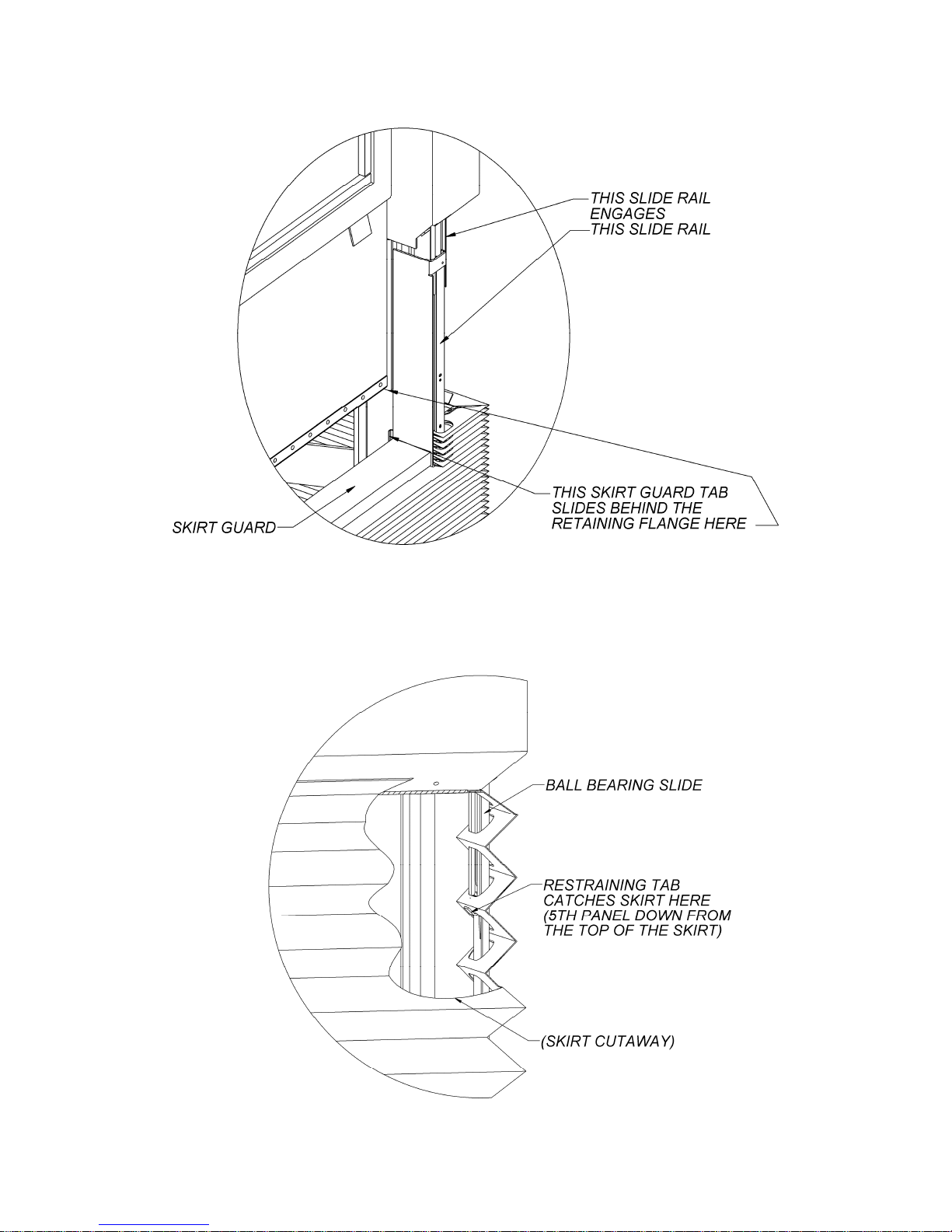

5. In the back, retract the skirt around the ball-bearing slides as shown in the figure at

the top of the following page. You will need to hold each skirt panel approximately

horizontal to move it past the restraining tab.

Maintenance & Repair Manual SECTION 3

VIRTUOSO 5460P

11 110057 REV K

6. Push the ball bearing slide releases toward the right side of the lift and then pull

downward on the skirt guard to separate it from the lift car.

7. At the front of the skirt, use pliers or a similar tool to turn the skirt guide tubes

counterclockwise until they release from the studs in the base. You will need to lift

the corners of the skirt to gain access to the skirt guide tubes.

8. Retract the skirt guide tubes through the slots in the skirt. The skirt is now free of

the lift. Use extreme care to support the skirt in its natural position as much as

Maintenance & Repair Manual SECTION 3

VIRTUOSO 5460P

12 110057 REV K

possible while moving it. A minimum of two (2) people is recommended for moving

the skirt.

To reinstall the lift car skirt, perform the following steps in the order indicated. If

necessary, refer to the figures in the skirt removal instructions above for identification of

skirt components.

1. Raise or lower the lift car so that the lift car floor is approximately 15" off the ground.

2. Move the skirt into position around the lift car, approximately as it will be located

when installed on the lift. Use extreme care to support the skirt in its natural position

as much as possible while moving it. A minimum of two (2) people is recommended

for moving the skirt.

3. At both front corners of the lift car, lift the skirt guide tubes upward, move the skirt

into place, and insert the guide tubes through the slots in the skirt. Then turn the

guide tubes clockwise onto the base studs, using pliers to tighten them.

4. In the back, reinstall the skirt guard onto the lift car by performing the following

steps. Refer to the figure at the top of the following page as necessary.

a. Position the skirt guard underneath the ball-bearing slide rails on the lift car, so

that the slide rails on the skirt guard line up with the slide rails on the lift car.

b. Move the skirt guard upward, while making sure that the skirt guard tabs slide

behind the retaining flanges on the lift car, and that the slide rails on the skirt

guard lock into the slide rails on the lift car.

c. You will feel and hear a "click" when the ball-bearing slide rails engage each

other, and the skirt guard will be held in place. If the skirt guard was installed

correctly, the guard cannot be pulled away from the lift car. If this is not the case,

use the release levers to release the skirt guard and then reinstall it, taking care

to slide the skirt guard tabs behind the retaining flanges on the lift car.

CAUTION!

In the following step, stay clear of the lift car when it is moving to avoid any

pinching and/or crushing hazards.

Maintenance & Repair Manual SECTION 3

VIRTUOSO 5460P

13 110057 REV K

5. Lift the skirt upward on both sides of the skirt guard until the skirt slips past the

restraining tabs on the ball bearing slides as shown in the figure below. The

restraining tab must catch the skirt on the 5th panel down from the top of the skirt.

Maintenance & Repair Manual SECTION 3

VIRTUOSO 5460P

14 110057 REV K

6. Use a Phillips screwdriver to reinstall two (2) or three (3) pan head screws on each

side of the lift car to secure the top of the skirt loosely to the lift car.

7. Use a 5/16" combination wrench to reinstall the four (4) hex head screws that secure

the top of the skirt to the lift car, one (1) at each corner. Be sure to install the skirt

support brackets between the skirt and the lift car frame. See the figure below.

8. Use a Phillips screwdriver to reinstall the remainder of the 28 pan head screws that

secure the sides of the skirt to the lift car at the top and to the lift base at the bottom.

9. Use a Phillips screwdriver to reinstall the pan head screw that secures the back of

the skirt to the base.

Maintenance & Repair Manual SECTION 3

VIRTUOSO 5460P

15 110057 REV K

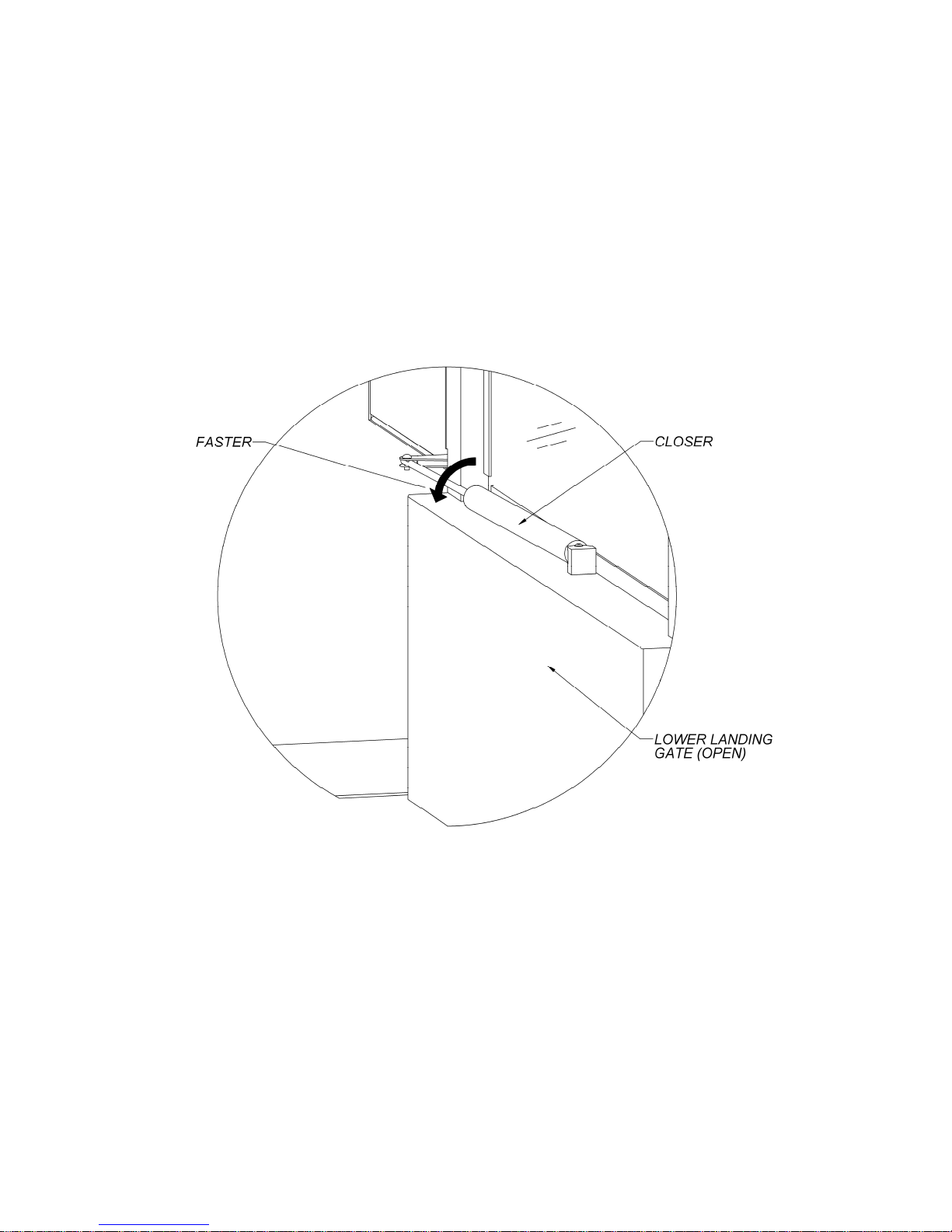

3.5 Lower Landing Gate Closer

To make the lower landing gate close faster, turn the gate closer

counterclockwise, 1/2 rotation at a time. To make the lower landing gate close

slower, turn the gate closer clockwise, 1/2 rotation at a time. See the figure

below.

Table of contents

Other Ascension Lifting System manuals

Popular Lifting System manuals by other brands

Haklift

Haklift SAKPBP Original instructions

Anchor

Anchor APEX 80 Use and maintenance

aidapt

aidapt VA147F Fitting and Maintenance Instructions

probst

probst FTZ-I Translation of original operating instructions

EAE

EAE EE-6435V2.B.PD Installation, operation, and parts manual

CMC

CMC S28 Use and maintenance manual

LSI-Robway

LSI-Robway RCI-1502 LM instruction manual

Harmar Mobility

Harmar Mobility HIGHLANDER EPL400 Installation and owner's manual

Terex

Terex Genie GS84D-401 Service and repair manual

TAWI

TAWI VM30 user guide

Sinoboom

Sinoboom TB20J Plus Operation manual

Skyjack

Skyjack Telescopic Boom Series operating manual