17

Change suction foot, quick

release

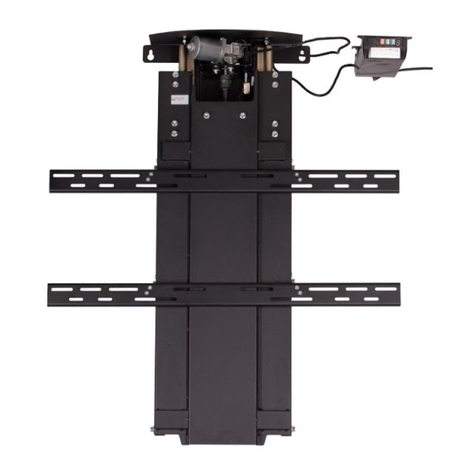

The lifter can be equipped with optional tools for

dierent load types. The quick change attachment

enables easy tool changes.

1. If not done, mount the quick change attachement

on the suction head and foot according to the

instructions for Install suction foot and touch bolt on

page 10.

2. With the suction foot resting on a rm surface and

the vacuum pump turned o, pull and hold the

spring-loaded pins.

3. Remove the suction foot.

4. Verify that the suction foot is correct for your

model and the colour code matches (see warning

below).

5. Connect the new suction foot to the suction head

by rmly pressing it in the quick change attach-

ment until the spring-loaded pins engage.

6. Verify that the suction foot is rmly connected to

the suction head and that it does not rotate.

7. Verify that the lift unit hangs and moves freely so

that unneccessary wear is avoided.

8. Verify function of the lifter.

Note the colour code system for safe assembly of lift unit to suction foot/accessory. Each colour

corresponds to a specic VacuEasylift model. ONLY PARTS WITH MATCHING COLOUR CODE

MARKING MAY BE ASSEMBLED! Some suction feet/accessories may be used with several lift mod-

els (indicated by the colour code). Incorrect combinations of lift unit and accessory may cause seri-

ous injuries.

Clean suction foot lter

The suction foot air lter should be cleaned regulary

(once a week, more often if the environment requires).

1. Remove the suction foot.

2. Carefully clean the air lter using reduced com-

pressed air.

3. The lter inset MUST be replaced when dirty or

damaged.

4. Fit the suction foot with two or four M6/M8 bolts

to the suction head, see Install suction foot and touch

bolt on page 10. Use a torque between 2-3 Nm

for the bolts.

5. Verify function of the lifter.

VM100 VM120 VM140 VM160 VM180 VM200 VM230 VM250 VM300

VM100 VM120 VM140 VM160 VM180 VM200 VM230 VM250 VM300

VM100 VM120 VM140 VM160 VM180 VM200 VM230 VM250 VM300

VM100 VM120 VM140 VM160 VM180 VM200 VM230 VM250 VM300