Installation, Operation and Parts Manual

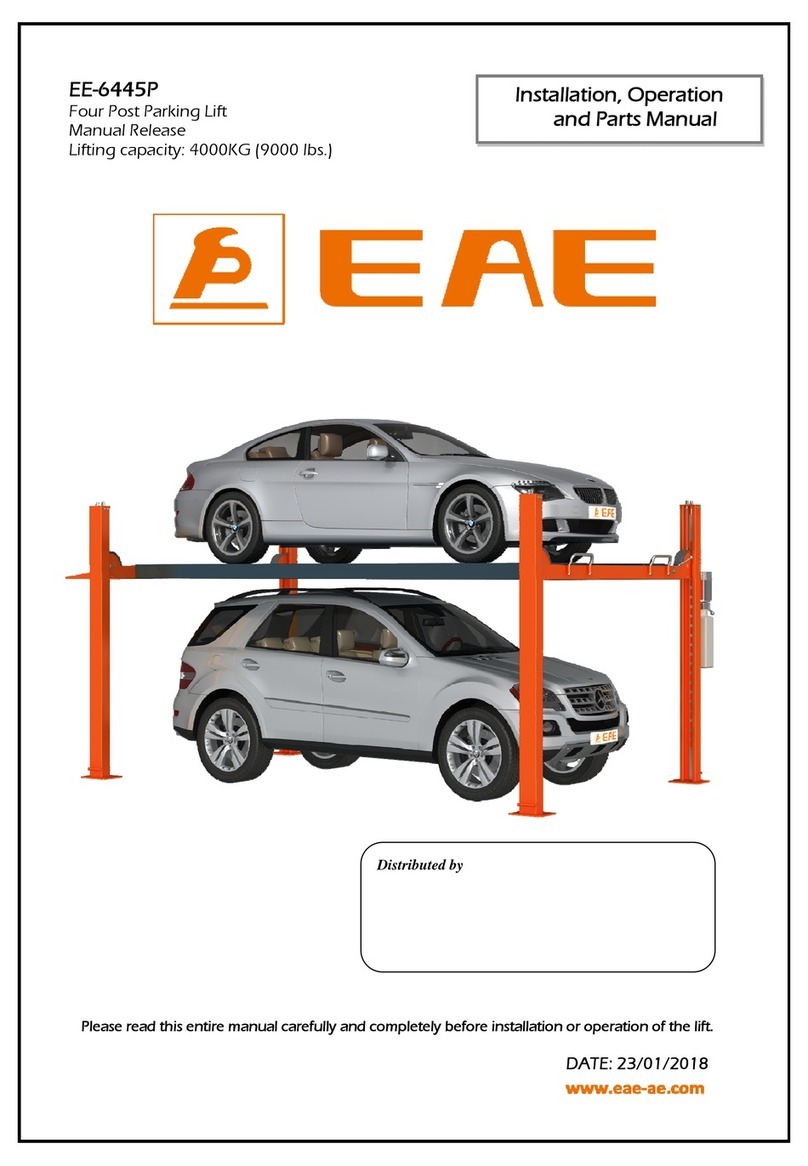

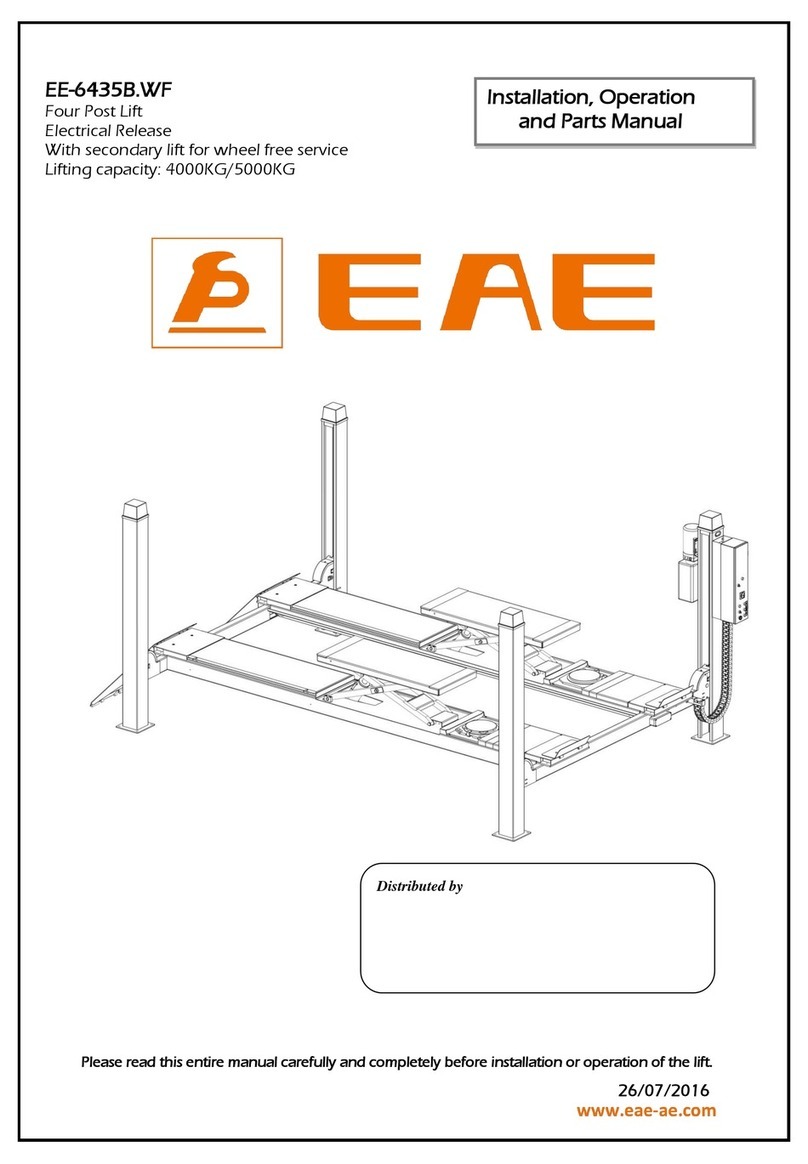

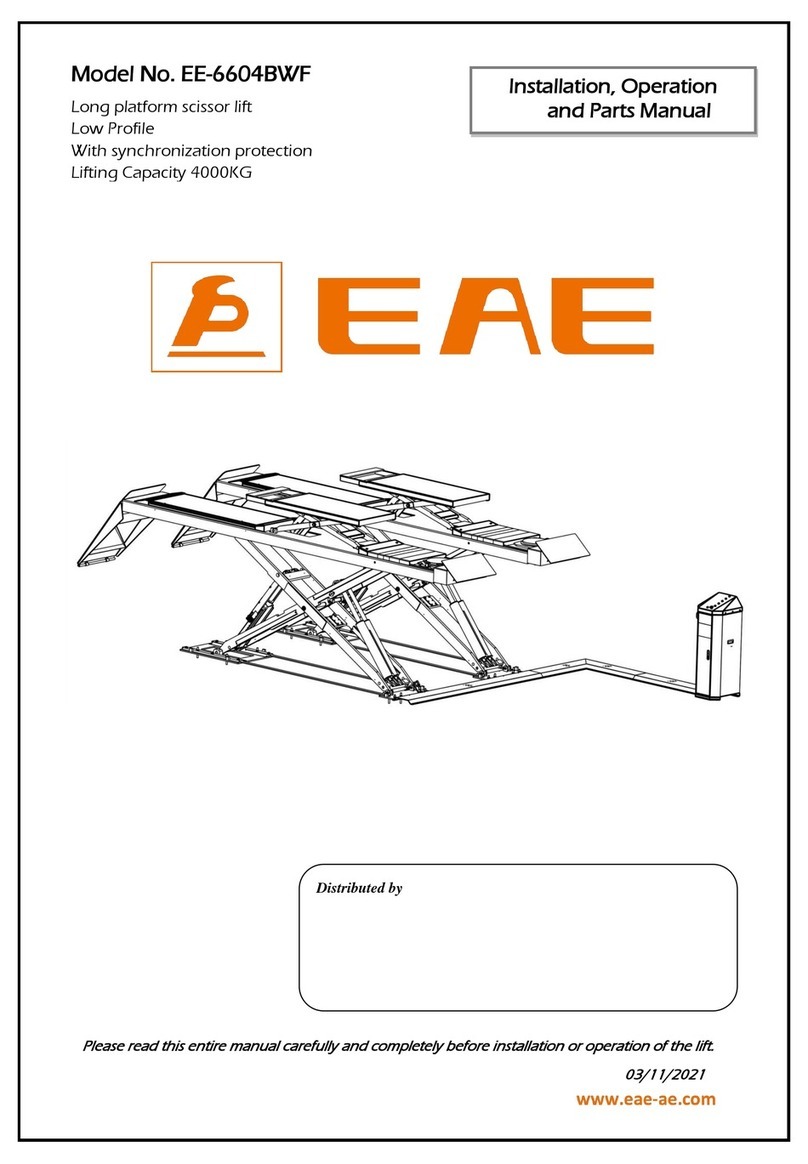

EE-6435BWF

IMPORTANT NOTES .............................................................................................................................................................2

SAFETY NOTES .....................................................................................................................................................................4

1.1 Operation of lifting platforms ............................................................................................................................................... 4

1.2 Checking of the lifting platforms........................................................................................................................................... 4

1.3 Important safety notices ....................................................................................................................................................... 5

1.4 Safety duties.......................................................................................................................................................................... 6

1.5 Potential risks and safety measures...................................................................................................................................... 7

1.6 Noise level ............................................................................................................................................................................. 7

PACKING, STORAGE AND TRANSPORTATION .......................................................................................................................8

2.1 The lift was dismantled into the following 2 parts for transportation.................................................................................. 8

2.2 Storage .................................................................................................................................................................................. 8

2.3 Lifting and handling............................................................................................................................................................... 8

PRODUCTS DESCRIPTIONS ...................................................................................................................................................9

3.1 General descriptions ............................................................................................................................................................. 9

3.2 Construction of the lift .......................................................................................................................................................... 9

3.3 Dimensions.......................................................................................................................................................................... 10

3.4 Safety devices descriptions ................................................................................................................................................. 11

3.5 Technical data ..................................................................................................................................................................... 12

3.6 Nameplate........................................................................................................................................................................... 12

INSTALLATION INSTRUCTIONS ...........................................................................................................................................13

4.1 Preparations before installation ......................................................................................................................................... 13

4.2 Installation attentions ......................................................................................................................................................... 16

4.3 General installation steps.................................................................................................................................................... 16

4.4. Items to be checked after installation ............................................................................................................................... 26

OPERATION INSTRUCTIONS ...............................................................................................................................................26

5.1 Precautions ......................................................................................................................................................................... 26

5.2 Descriptions of control panel .............................................................................................................................................. 27

5.3 Operation instructions ........................................................................................................................................................ 27

5.4 Emergent lowering in case of no power supply .................................................................................................................. 29

TROUBLE SHOOTING..........................................................................................................................................................30

MAINTENANCE ..................................................................................................................................................................31

Annex 1, Steel cable connection ............................................................................................................................................... 33

Annex 2, Electrical schemes and parts list ................................................................................................................................ 34

Annex 3, Hydraulic schemes and parts list................................................................................................................................ 40

Annex 4,Exploded drawings and parts list ................................................................................................................................ 44