Ascension 16C User manual

ASCENSION CLARITY

WHEELCHAIR LIFT

16C/D/E/S MODEL SERIES

PRODUCT MANUAL

16C

16D

16E

16S

Same-Side,

Shaftway

Same-Side,

Enclosed

Straight-Through,

Enclosed

Straight-Through,

Shaftway

For patent information, see ascension-lift.com/patents

By Philip Brobeck at 8:41 am, Jul 16, 2021

Copyright © 2021 Ascension, a Division of AGM, Tucson, Arizona

http://ascension-lift.com

This document, or parts thereof, may not be reproduced in any form, by any method, for

any purpose, without written permission from Ascension.

ASCENSION CLARITY

WHEELCHAIR LIFT

16C/D/E/S MODEL SERIES

PRODUCT MANUAL

16C

16D

16E

16S

Same-Side,

Shaftway

Same-Side,

Enclosed

Straight-Through,

Enclosed

Straight-Through,

Shaftway

For patent information, see ascension-lift.com/patents

TABLE OF CONTENTS

SECTION 1GENERAL.................................................................................................. 7

1.1Product information ......................................................................................... 7

1.2Definitions ....................................................................................................... 8

1.3Important safety information............................................................................ 9

SECTION 2OPERATION............................................................................................ 10

2.1Description of operation ................................................................................ 10

2.2Standard operation........................................................................................ 11

2.3Manual lowering ............................................................................................ 12

2.4Manually unlocking doors.............................................................................. 13

2.5Using the service override controls ............................................................... 13

SECTION 3BASIC MAINTENANCE AND TROUBLESHOOTING.............................. 14

3.1Routine maintenance .................................................................................... 14

3.2Basic troubleshooting.................................................................................... 14

SECTION 4ADVANCED TROUBLESHOOTING........................................................ 15

4.1Advanced troubleshooting............................................................................. 15

SECTION 5MECHANICAL DISASSEMBLY AND REPAIR ........................................ 16

5.1Safety procedures ......................................................................................... 16

5.2Removing the fascia panels .......................................................................... 17

5.3Removing the upper covers (16E, 16S) ........................................................ 18

5.4Mechanically blocking the platform ............................................................... 19

5.5Hydraulic drive system .................................................................................. 20

5.6Platform safeties ........................................................................................... 22

5.7Slack chain switches ..................................................................................... 23

5.8Lower terminal switch.................................................................................... 24

5.9Upper terminal switch and creep switch........................................................ 25

5.10Door lock switches ........................................................................................ 26

5.11Traveling cable.............................................................................................. 27

5.12Platform operating station ............................................................................. 28

5.13Windows........................................................................................................ 28

5.14Disassembling and detaching the platform.................................................... 31

5.15Runway enclosure (16E, 16D) ...................................................................... 33

SECTION 6ELECTRICAL TESTING AND ADJUSTMENT......................................... 35

6.1Access to the lift controller ............................................................................ 35

6.2Controller diagnostic lights ............................................................................ 36

6.3Removing the controller subpanel................................................................. 39

6.4Testing the switches...................................................................................... 39

6.5Testing supply of power to lift and motor....................................................... 39

6.6Testing the power supply .............................................................................. 40

6.7Testing the batteries...................................................................................... 40

6.8Testing the controller fuse ............................................................................. 41

6.9Testing the motor fuse .................................................................................. 41

6.10Testing the SSR (motor relay)....................................................................... 42

6.11Adjusting alarm volume................................................................................. 43

6.12Two-way communication system .................................................................. 43

6.13Adjusting the illumination .............................................................................. 44

6.14Adjusting/testing the optional power door operators ..................................... 45

6.15Electrical diagram.......................................................................................... 46

SECTION 7INSPECTIONS ........................................................................................ 49

7.1System specifications.................................................................................... 49

7.2Test platform safeties.................................................................................... 49

CLARITY 16C/D/E/S Product Manual SECTION 1

7 117020 Rev C

SECTION 1 General

1.1 Product information

Operational ratings

OCCUPANCY: 1 person

RATED LOAD: 750 pounds (340kg)

AVERAGE SPEED: 20 feet per minute (0.1 m/s)

DUTY CYCLE: 15 minutes of operation per hour repetitive use

(10 cycles for 168” lifting height)

22 minutes maximum single runtime

(15 cycles for 168” lifting height, followed by full cool-down)

Physical ratings

PLATFORM SIZE: 36" wide x 56" long, 42” minimum side height

MATERIALS: Platform, base frame, lifting device: Mild steel

Accent rails and grab bar: Stainless steel

Guide rails and enclosure framing: Aluminum alloy

Windows: High impact strength clear thermoplastic

FINISH: Oven-baked powder coat

Brushed stainless

ELECTRICAL: Input power: 120VAC, 60Hz, 6A, single phase

Motor: 24VDC, 3hp (2.1kW)

Batteries: 2X 12VDC 35A-h AGM SLA batteries

Duracell® Ultra DURA12-35C

Control circuits: 24VDC

CLARITY 16C/D/E/S Product Manual SECTION 1

8 117020 Rev C

1.2 Definitions

Emergency stop switch The red pushbutton provided at the platform operating

station. Pushing this button immediately stops the lift until it is manually reset.

Fascia The smooth surface extending from the upper landing sill to the level of the

lower landing.

Fascia panel One of the sheet metal covers used to enclose the machinery cabinet

and form the fascia.

Guide rails The vertical tracks that the platform travels on and form the sides of the

machinery cabinet.

Lower landing The lower-elevation level that the lift serves.

Lower landing door The door providing access to the platform from the lower landing.

Machinery cabinet The enclosed space in which the lifting and control mechanisms

are located. The machinery cabinet forms the rear wall of the runway and extends

from the lower landing to the upper landing.

Operating stations The controls for raising and lowering the platform. The operating

station inside the platform has an emergency stop switch. The operating stations

outside the platform may be mounted remotely.

Operating switch An up/down rocker switch used to raise/lower the platform.

Platform The traveling cab that carries a passenger between levels.

Platform brackets The weldments extending from the machinery cabinet that the

platform mounts to.

Runway The vertical space through which the platform moves as it travels between

landings.

Runway enclosure The walls or barriers that surround the runway, restricting access

to the inside of the runway.

Upper landing The higher-elevation level that the lift serves.

Upper landing door The door providing access to the platform from the upper landing.

CLARITY 16C/D/E/S Product Manual SECTION 1

9 117020 Rev C

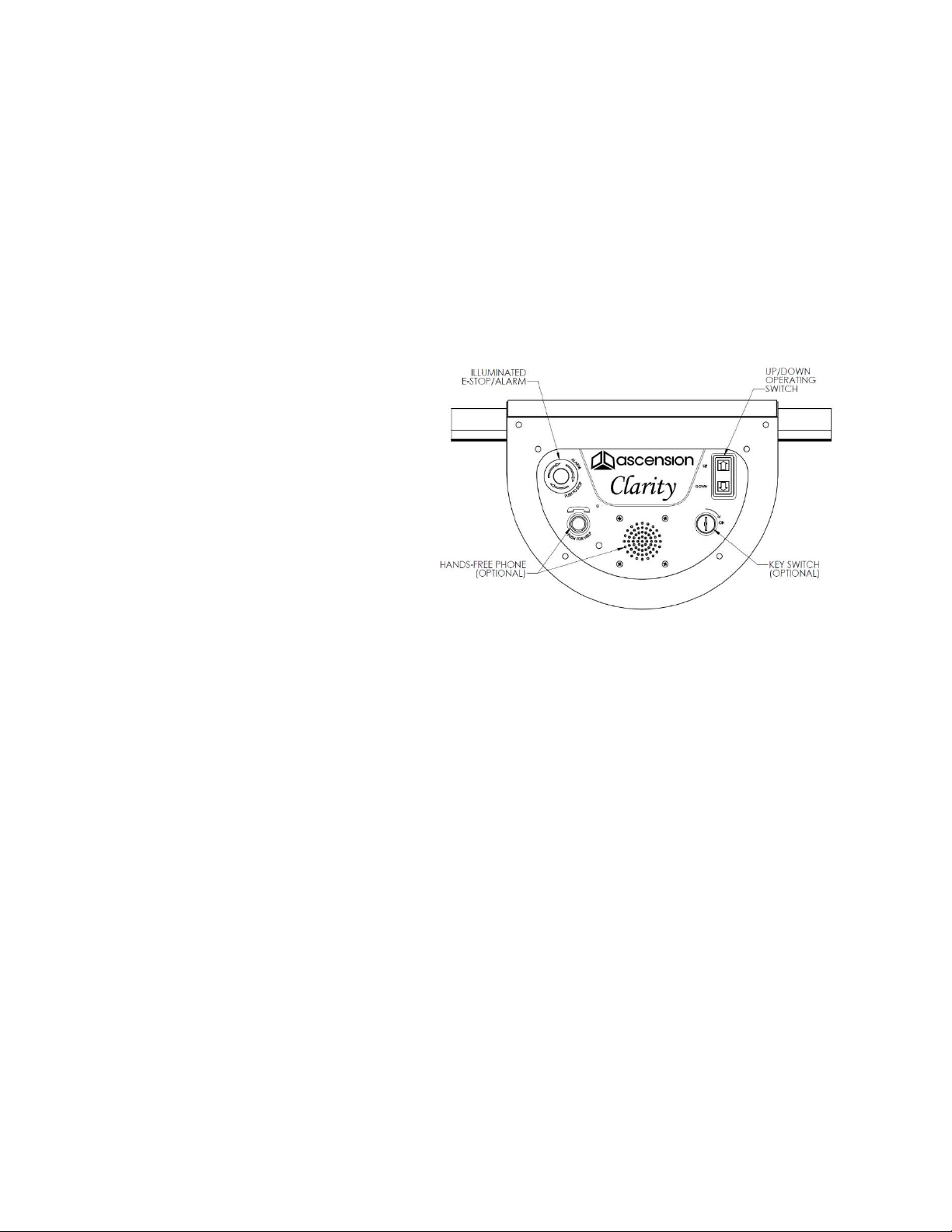

Figure 1: Parts identification

1.3 Important safety information

When using the lift, the following basic safety precautions and practices must be

observed:

1. Read and understand all of the information contained in this manual.

2. Do not overload the platform. The lifting capacity is 750 lbs.

3. Operate the lift only as described in Section 2 of this manual.

4. Use the lift for movement of people only.

5. Do not expose any part of the lift to a direct liquid stream or spray, such as a

water hose. This could create an electrical shock or fire hazard.

6. Do not operate the lift in the presence of combustible or explosive gas or fumes.

The electrical components of the lift could cause ignition of these chemicals.

CLARITY 16C/D/E/S Product Manual SECTION 2

10 117020 Rev C

SECTION 2 Operation

2.1 Description of operation

Vertical motion of the platform is controlled by the three (3) operating switches located

in the platform and at the landings. While any switch is in use, the other switches are

disabled. These are constant-pressure type switches, meaning that the platform stops

when the switches are released.

A door at each landing permits passengers to enter and exit the platform. Each door is

equipped with an electric lock that prevents the door from being opened while the

platform is away from the given landing, ensuring the safety of those inside and outside

the platform. Both doors are self-closing.

Two parallel-connected hydraulic cylinders raise and lower the platform. When the "Up"

circuit is energized, an electric motor operates a hydraulic pump which provides

pressurized hydraulic fluid to the cylinders, causing the cylinder rods to extend and raise

the platform. When the "Down" circuit is energized, a hydraulic valve is opened to allow

a controlled, gravity-driven descent. It takes approximately 45 seconds for the platform

to travel in either direction through its maximum travel range of 168 inches (14 feet).

The lift is equipped with standard battery backup that allows the platform to be operated

up and down at least five (5) cycles in the event of a power outage. Additionally, the lift

is equipped with a manual lowering pull handle that can be used to lower the platform in

an emergency. Use of the override pull handle is restricted to authorized personnel

only. The platform will descend at a controlled speed as long as the handle is pulled

until it rests at the lower landing.

The drive unit and electrical controller are located at the base of the machine cabinet,

behind the bottom fascia panel. Equipment at this location includes the motor, pump,

power supply, batteries, controller circuit board, and motor relay.

CLARITY 16C/D/E/S Product Manual SECTION 2

11 117020 Rev C

2.2 Standard operation

The main power disconnect for the lift must be in the “on” position for the lift to

operate, even on battery power.

Both landing doors must be closed and locked for the platform to operate.

Each landing door unlocks for as long as the platform remains at that landing.

Pressing an operating switch in a valid direction of travel will lock the door.

Move the platform using any of

the three (3) operating switches.

The operating switches must be

held with constant pressure until

the platform stops at the upper or

lower landing. Releasing the

switch will stop the platform.

Push the emergency stop button

to immediately prevent any

up/down motion and cause the

audible alarm to sound. Turn clockwise to deactivate and reset the switch.

If included, press the “PUSH FOR HELP” button to call a preprogrammed number.

See Section 6.12 for the communication system configuration information.

By default, the platform lighting will illuminate for at least thirty (30) seconds when

either door is opened or any operating switch is used. Lighting also activates during

an AC power outage. See Section 6.13 for information on adjusting brightness or

mode of operation. See Section 6.11 for adjusting alarm volume.

If the lower landing door is equipped with an automatic operator, press a “down”

operating switch while the platform is present at that landing to open the door. If the

upper landing door is equipped with an automatic operator, press an “up” operating

switch while the platform is present at that landing to open the door. Each operator

will hold the door open for a set time period and then automatically close the door.

Figure 2: Platform operating station

CLARITY 16C/D/E/S Product Manual SECTION 2

12 117020 Rev C

2.3 Manual lowering

The manual lowering pull handle can be used to lower the platform when power is

unavailable. It is operated from upper landing (16E, 16S) or lower landing (16C, 16D).

1. 16E, 16S:

a. Locate pull handle at the upper landing, near the base of the upper landing

door (See Figure 3, 16E/16S). Remove the torx head screw to release

manual lowering pull handle.

b. Push on the near end of the manual lowering pull handle to rock the far end

upward. Pull the handle up and out of the floor plate until you feel tension in

the steel cable attached to the handle.

c. Pull the handle to override the hydraulic lowering valve and lower the

platform. Do not pull with more than 20 pounds of force.

2. 16C, 16D (or any lift equipped with remote manual lowering package):

a. Unlock and open the manual lowering access box (see Figure 3, 16C, 16D).

b. Pull the handle to override the hydraulic lowering valve and lower the

platform. Do not pull with more than 20 pounds of force.

NOTICE

Do not pull handle with more than 20 pounds of force. If the

platform still does not descend, the platform safeties may be

holding the platform in place. Contact a repair technician.

16E, 16S 16C, 16D

Figure 3: Manual lowering

-OR-

CLARITY 16C/D/E/S Product Manual SECTION 2

13 117020 Rev C

2.4 Manually unlocking doors

To manually unlock a locked door, the interlocks locking each door may be manually

overridden. See section 5.10.2.

2.5 Using the service override controls

Certain maintenance and repair tasks require movement of the platform at times when

the safety switches would normally prevent motion. In these circumstances, the service

override controls can be used to bypass the control circuits and directly switch on the

lowering valve or the motor and up valve. The service override controls are an up and

down button on a hand-held pendant to be connected to the lift only when needed.

The service override controls are only intended for use by Ascension dealers and

authorized service companies.

Exercise EXTREME CAUTION while using the service override controls, as they

exist for the express purpose of bypassing the lift’s safety features.

WARNING

CRUSHING AND SHEARING HAZARDS RESULTING IN

SERIOUS INJURY OR DEATH MAY BE PRESENT WHILE

OPERATING THE PLATFORM USING THE SERVICE

OVERRIDE CONTROLS. EXERCISE EXTREME CAUTION.

To use, first remove the bottom fascia panel and electrical box cover as described in

section 5.2, then plug the service override control into the DIN connector on the main

circuit board. Use the buttons on the controller to move the platform up and down.

Using the service override controls will cause the controller circuit board to enter a fault

mode and lock out normal operation. To restore normal operation, reset the controller

using the reset button or the main electrical disconnect switch (see Figure 15 on page

35).

CLARITY 16C/D/E/S Product Manual SECTION 3

14 117020 Rev C

SECTION 3 Basic maintenance and troubleshooting

3.1 Routine maintenance

The owning facility is responsible for the proper maintenance of the lift. The following

checks must be performed every six (6) months:

1. Verify the operation of the lift per Section 2.

2. Verify that the lower platform door interlock engages before the platform moves from

the lower landing. Verify that the upper landing door interlock engages before the

platform moves from the upper landing.

3. Verify that the hydraulic oil in the reservoir (behind the bottom fascia panel at the

base of the machine cabinet) is between the MIN and MAX levels when the platform

is at the lower landing. If the hydraulic oil is low, remove the black reservoir cap and

use a funnel and rubber hose to add more fluid. For indoor lifts use ISO 32 grade

hydraulic oil such as Texaco Rando HD32 or 76 Unax AW32 filtered to 10 microns.

For outdoor lifts use ISO 22 grade low-temperature hydraulic oil.

3.2 Basic troubleshooting

If the lift will not operate, confirm the following before calling a service technician:

Both doors are fully closed.

The key switch (if present) on the operating station in use is in the ON position.

The emergency stop button is not actuated.

The main power disconnect switch is in the ON position.

The branch circuit supplying the lift does not have a tripped breaker or blown fuse.

If these conditions are satisfied but the lift does not operate, contact an authorized

service technician (usually the company that installed the lift). Advanced troubleshooting

to be performed by the technician can be found in Section 4.

CLARITY 16C/D/E/S Product Manual SECTION 4

15 117020 Rev C

SECTION 4 Advanced troubleshooting

4.1 Advanced troubleshooting

Troubleshooting in this section is to be performed by a licensed service technician. See

Section 3.2 for basic troubleshooting before contacting a licensed service technician.

Problem Possible Cause Remed

y

Section Pa

g

e

Platform will not

raise or lower

Hydraulic shutoff valve

is closed

Open shutoff valve 5.1.2 16

Lift controller is in fault

mode

Reset lift controller 6.2 36

Slack chain switches

have been actuated

Restore tension and

reset switches

5.7 23

Disconnected wire Check lift controller

li

g

hts and reconnect

6.2 36

Component failure Electrical testing –

possible component

replacement

6.0 35

Motor does not

run & platform

does not raise

Batteries are

disconnected, dead,

and/or not char

g

in

g

Reconnect red battery

connectors or replace

batteries

5.1.1

6.7

16

40

Motor runs but

platform does

not raise

Shutoff valve is closed Open shutoff valve 5.1.2 16

Low fluid level Fill reservoi

r

3.1 14

Up valve not activating Electrical testing –

possible component

replacement

5.5.1 20

Platform does

not stop level

with landing

Cylinder stop collar set

too low

(

lower landin

g)

Adjust cylinder stop

colla

r

5.5.2 20

Terminal switch

actuating early/late

(

either landin

g)

Adjust terminal switch

actuator

5.8

5.9

24

25

Landing door

will not open

Lower/upper terminal

switch not actuating

Adjust terminal switch

actuator or cylinder stop

5.8/5.9

5.5.2

24

25

20

Disconnected interlock

or terminal switch wire,

or component failure

Electrical testing –

possible component

replacement

5.10

6.2

26

36

Landing door

will not lock

Interlock manually

overridden

Un-override interlock 5.10 26

CLARITY 16C/D/E/S Product Manual SECTION 5

16 117020 Rev C

SECTION 5 Mechanical disassembly and repair

5.1 Safety procedures

The repairs in this section are to be performed by a skilled technician who has

experience working on electromechanical systems and is well versed in standard

industrial safety practices and procedures. In the United States of America, electrical

safety procedures are established in OSHA’s Lockout/Tagout – Hazardous Energy

Sources Standard (29 CFR 1920.147).

Familiarity with the setup and operation of the lift described in previous sections of this

manual is required to effectively perform the repairs listed in this section.

5.1.1 Electrically isolating the lift

To electrically isolate the lift, turn the manual disconnect installed with the lift to the OFF

position. This will completely isolate the lift from AC power and disconnect the logic

controller from DC power from the built-in backup batteries, eliminating the possibility of

unexpected platform movement.

While servicing the lift, be aware that some parts will remain live at 24VDC due to

connection to the batteries. To isolate the batteries, open the machinery cabinet and

disconnect the red battery connectors located just above the left battery.

5.1.2 Hydraulically isolating the pumping unit

A shutoff valve is provided to isolate the hydraulic power unit from the lifting cylinders. It

is located just to the left of the electrical box in the base of the machine cabinet, just

above the motor and pumping unit. Close this valve during servicing to prevent

unintended motion of the platform.

To close the shutoff valve and isolate the pump from the cylinders, turn the handle

horizontal, perpendicular to the tubes connected to the body of the valve. While the

shutoff valve is closed, the pump and lowering valve cannot move the platform.

CLARITY 16C/D/E/S Product Manual SECTION 5

17 117020 Rev C

5.2 Removing the fascia panels

Most of the functional components inside the machinery cabinet can be accessed by

removing the bottom fascia panel while the platform rests at the lower landing.

WARNING

CRUSHING AND SHEARING HAZARDS EXIST WHILE

OPERATING THE PLATFORM WITH ONE OR MORE FASCIA

PANELS REMOVED. EXERCISE EXTREME CAUTION.

1. Remove the two (2) screws just above the platform floor fastening the bottom fascia

cover. Set the cover aside.

2. Remove the four (4) screws near the top of the bottom fascia panel.

3. Slide the fascia panel up to remove it, taking care not to scratch the other panels.

4. Remove additional panels in the same manner.

5. To reinstall panels, perform the above steps in reverse order. Install screws with a

manual screwdriver, finding the existing threads by feel.

NOTICE Reinstalling fascia panel screws with a power driver is likely

to damage the threads and result in loose fixing.

CLARITY 16C/D/E/S Product Manual SECTION 5

18 117020 Rev C

5.3 Removing the upper covers (16E, 16S)

The upper covers form the insides of the side posts at the upper landing and support

the upper door and strike. Removal of these covers grants access to the upper terminal

switch, creep switch, and upper door interlock switch.

WARNING FALLING HAZARD WHEN UPPER DOOR IS REMOVED AND

PLATFORM IS NOT AT UPPER LANDING.

CAUTION PINCHING HAZARD WHEN UPPER COVERS ARE

REMOVED. EXERCISE CAUTION.

1. Raise the platform to the upper landing to prevent falling when the upper door is

removed. Otherwise, use fall protection and restrict access to the area.

2. Manually unlock the door per the instructions in section 5.10.2.

3. Remove the hinge-side upper cover (with door attached) by removing two (2) screws

fastening it to the top of the side rail, all screws fastening it to the vertical face of the

side rail, and three (3) screws attaching it to the landing plate at the bottom.

4. Unfasten the strike-side upper cover (with door interlock switch attached) in the

same manner as the hinge-side cover. However, the strike-side upper cover is fixed

at the bottom with only two (2) screws.

5. Lift the strike-side upper cover up several inches to expose the cord from the upper

door interlock switch. Disengage the cord from the U-shaped slot in the landing

plate and pull it up another several inches to find the connectors labeled “P5.”

Disconnect the connectors and take precautions to prevent the lower wiring harness

from falling down into the machine cabinet. If present, also disconnect the

connectors from the back of the operating station mounted over the skin.

6. After servicing, reassemble by performing the steps above in reverse order. Take

care not to pinch the cable from the upper door interlock switch during installation; it

must be routed through the “hole” formed by the opposing U-shaped cutouts in the

landing plate and upper strike-side cover.

CLARITY 16C/D/E/S Product Manual SECTION 5

19 117020 Rev C

5.4 Mechanically blocking the platform

Most repairs on the Clarity lift can be accomplished with the platform resting at the lower

landing. Ascension recommends against working under the raised platform unless it is

necessary to do so. Any time work will be performed under the platform, it must first be

blocked. Never place a load on the platform while it is supported by mechanical

blocks.

WARNING RISK OF CRUSHING. DO NOT PLACE ANY LOAD ON THE

PLATFORM WHILE IT IS BLOCKED FOR SERVICE.

Provision and use of blocking means is the responsibility of the servicing company.

Blocking means must be stable and capable of supporting 450 lb. (200 kg).

CLARITY 16C/D/E/S Product Manual SECTION 5

20 117020 Rev C

5.5 Hydraulic drive system

5.5.1 Description

The hydraulic system includes the hydraulic power unit, two (2) lifting cylinders, a

shutoff valve, and the tubing connecting the components. The hydraulic power unit

includes an integrated motor, pump, reservoir, and manifold with two solenoid valves:

Lowering valve: When the solenoid is energized, the valve opens and allows fluid to

flow out of the cylinders and back to the reservoir, lowering the platform by gravity.

Up valve: When the solenoid is energized, the valve closes to direct fluid to the

cylinders. When the valve is in its normally open state, fluid bypasses from the

pump directly back to the reservoir. This valve prevents the platform from coasting

above the upper landing and provides redundant safety with the motor relay.

To raise the platform, the motor and up valve are energized to pump fluid from the

reservoir through a tee to the parallel-connected cylinders. As the cylinders extend,

they raise the platform at double speed by means of a 2:1 chain suspension system.

As each cylinder extends, fluid stored in the rod end flows out the top port and refills the

reservoir. As gravity lowers the platform by retracting the cylinders, it creates a vacuum

in the rod end of the cylinder that draws fluid back into the empty volume, acting as

additional reservoir capacity.

5.5.2 Cylinder stop collars

A shaft collar installed at the top of each cylinder rod acts as a lower physical stop and

prevents the rod from retracting too far once the platform reaches the lower landing.

The stop collars should not normally need adjustment after initial installation of the lift. If

adjustment is necessary, loosen the screw on each collar then use the manual lowering

pull handle to lower the platform to where it rests on the ground without any slack in the

lifting chains. Slide each collar down until it contacts the top of the cylinder barrel and

tighten the screw to lock the location.

This manual suits for next models

3

Table of contents

Other Ascension Lifting System manuals

Popular Lifting System manuals by other brands

Ravaglioli

Ravaglioli KPN235WEK manual

SHARKS

SHARKS SH1088 Instruction for operation and maintenance

Lehner Lifttechnik

Lehner Lifttechnik SIGMA user manual

Vestil

Vestil CART-CTD Operation and maintenance manual

AAQ

AAQ AutoLift 163027 Installation manual & operation instructions

Borum

Borum B900TJL owner's manual

Yale Lift-Tech

Yale Lift-Tech 115325 Operation, service & parts manual

Bosch

Bosch VLE 21 Series Repair instructions

WITTUR

WITTUR WSG09 Operating and maintenance manual

ReadyLift

ReadyLift 67-2500CB quick start guide

Anthony Liftgates

Anthony Liftgates ETU-20-44 parts book

Mopedia

Mopedia RI840 instruction manual