2

POSIMATIC

INSTALLATION

Contents

1. Safety instructions ......................................................................................................................................... 3

1.1 General .................................................................................................................................................. 3

1.2 Description of symbols .......................................................................................................................... 3

1.3 Electrical and pneumatic safety instructions .......................................................................................... 4

1.4 Proper use ............................................................................................................................................. 4

1.5 Tools required for installation and connection ......................................................................................... 4

2. Manufacturer’s specifications ......................................................................................................................... 4

2.1 Scope of delivery ................................................................................................................................... 4

3. Mechanical assembly .................................................................................................................................... 5

3.1 Assembly to linear actuators ................................................................................................................. 5

3.2 Assembly to a rotary actuator ................................................................................................................ 5

3.3 External assembly ................................................................................................................................. 5

4. Pneumatic connections.................................................................................................................................. 6

5. Electrical connections .................................................................................................................................... 7

6. Operation ...................................................................................................................................................... 7

6.1 Controls and indicators .................................................................................................................................. 7

6.2 Access levels ........................................................................................................................................ 8

7. Startup ...................................................................................................................................................... 8

7.1 General operating instructions................................................................................................................ 8

7.2 Initialisation ........................................................................................................................................... 8

7.2.1Settings ......................................................................................................................................... 8

7.2.2Factory settings (positioner assembled to valve) ..........................................................................10

8. Operating modes...........................................................................................................................................10

8.1 Automatic mode (A: AUTO) ...................................................................................................................10

8.2 Manual mode (B: MANUAL) ..................................................................................................................10

8.3 Configuration (C: CONFIG) .................................................................................................................... 10

9. Integration of options ....................................................................................................................................11

9.1 Plug-in module for analog position feedback .........................................................................................11

10. List of parameters ......................................................................................................................................... 12

10.1 Description of parameters .....................................................................................................................13

11. Error messages ............................................................................................................................................ 18

12. Technical characteristics ...............................................................................................................................19

13. Assembly options .........................................................................................................................................20

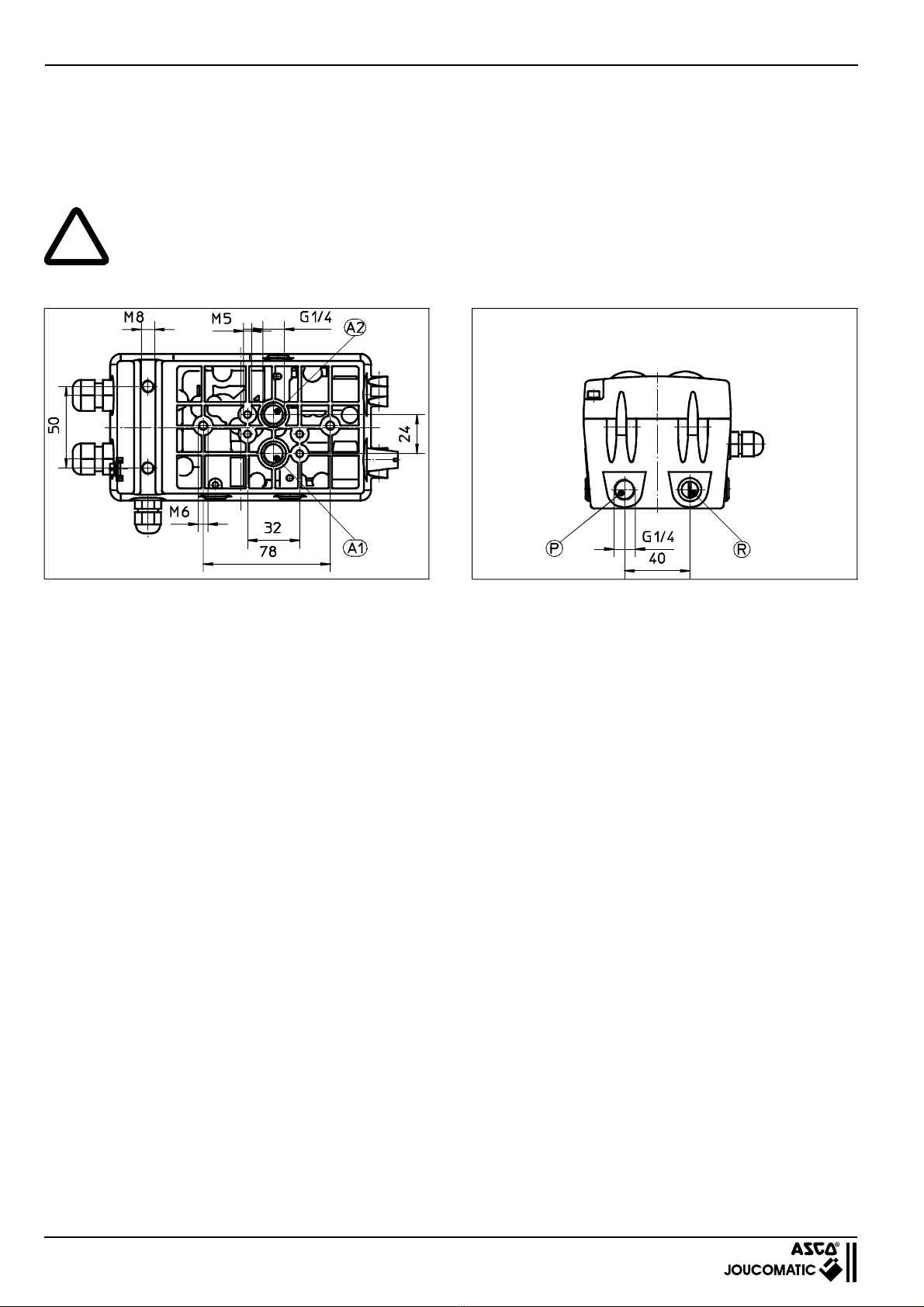

14. Dimensions ...................................................................................................................................................21

Index.....................................................................................................................................................................22

NOTICE

The information in this manual is subject to change without notice.

In no event shall ASCO/JOUCOMATIC be liable for technical or editorial errors or omissions. Neither is any

liability assumed for accidental or consequential damages arising out of or in connection with the supply or

use of the information contained herein.

THIS MANUAL CONTAINS INFORMATION PROTECTED BY COPYRIGHT. NO PART OF THIS DOCUMENT

MAY BE PHOTOCOPIED OR REPRODUCED IN ANY FORM OR MANNER WHATSOEVER WITHOUT

PRIOR WRITTEN PERMISSION FROM ASCO/JOUCOMATIC.

COPYRIGHT ©2000/2001 - ASCO/JOUCOMATIC - All rights reserved.