5GENERAL NOTES4

1. NOTES • GUIDELINES • GUARANTEE

1.1. GENERAL SAFETY NOTES

• When handling lithium-ion batteries, observe the applicable regulations and the information in these operating

instructions.

• Work on the electrical system is to be carried out only with the power turned o and only by qualified electri-

cians – refer here to the respective regulations for the prevention of accidents, the VDE regulations and the

regulations of the local electricity supply company.

• General damage to electronic components is to be repaired without delay by an asecos employee.

• Use only intact and undamaged mains cables for the battery charger

• Electrical protection in accordance with local standards must be provided by the customer (cabinets do not

have their own RCD circuit breaker or circuit breaker)

• The on-site installation conditions must be observed.

• The instructions of the supervisory engineering department must be followed.

• Observe accident prevention regulations and workplace ordinance.

• Ensure that the necessary safety checks are only carried out by authorised sta using original spare

parts.

• Only use the cabinet after having been properly instructed; access is to be forbidden to unauthorised persons.

• The pivoting area of the doors is to be kept free at all times; doors are to be kept closed.

• By assigning trained/authorised technical personnel you can prevent the malfunctions, damage and corrosion

damage that result from inappropriate transport.

• Observe the upper limits for stored quantities, loading etc.

• The following substances may not be stored in the cabinets with a fire suppression system: acids, alkalis,

magnesium, other metals (in powder form)

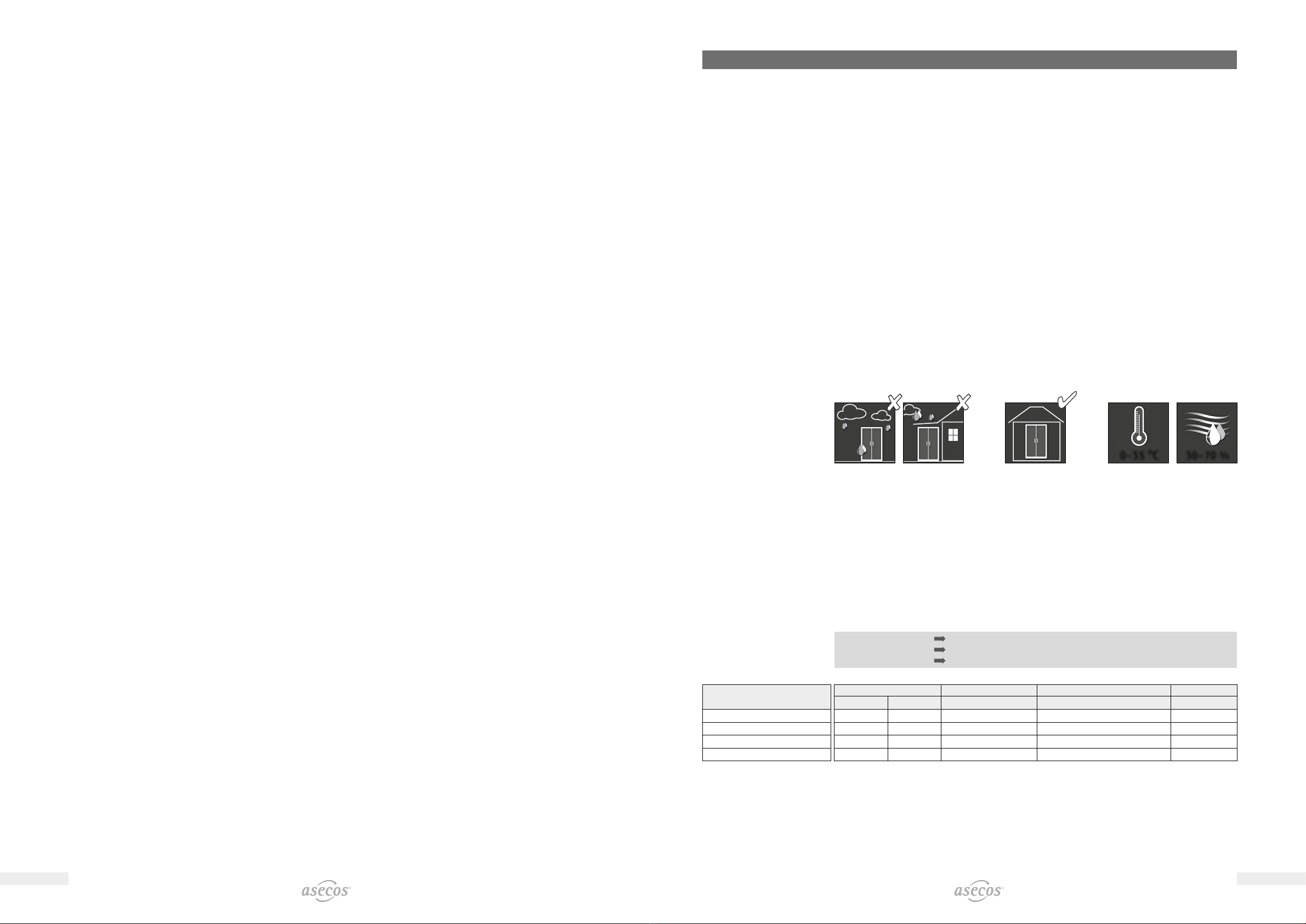

Installation and environmental conditions

0–35 °C 30–70 %

1.2. GUARANTEE

The guarantee for this product is agreed between you (the customer) and your dealer (the sel-

ler). As the manufacturer, asecos guarantees the products listed in the operating instructions for a

period of 24 months from the date of delivery.

All model safety equipments are subject to a compulsory annual inspection by specialised sta

authorised by the manufacturer. Otherwise the customer’s guarantee claim against the manufac-

turer expires.

1.3. CABINET DETAILS

Cabinet data logbook (included with the cabinet)

Technical drawing page 18

Technical data page 18

Models Lithium ion batteries

Storing Charging Extraction air unit Fire supression unit Alarm system

BATTERY CHARGE

IO90.195.060.K9.WDC 4 4 4

BATTERY CHARGE PRO

IO90.195.120.K3.WDC 4 4 4 4 4

BATTERY CHARGE & BATTERY CHARGE PRO

These models are for the active storage (charging) of lithium-ion batteries. .

With active storage, lithium-ion batteries or battery packs in the cabinet are charged or partially discharged

using a charger (60—70%).

GENERAL NOTES

1. NOTES • GUIDELINES • GUARANTEE ............................................. 5

1.1. General safety notes ............................................ 5

1.2. Guarantee ..................................................... 5

1.3. Cabinet details ................................................. 5

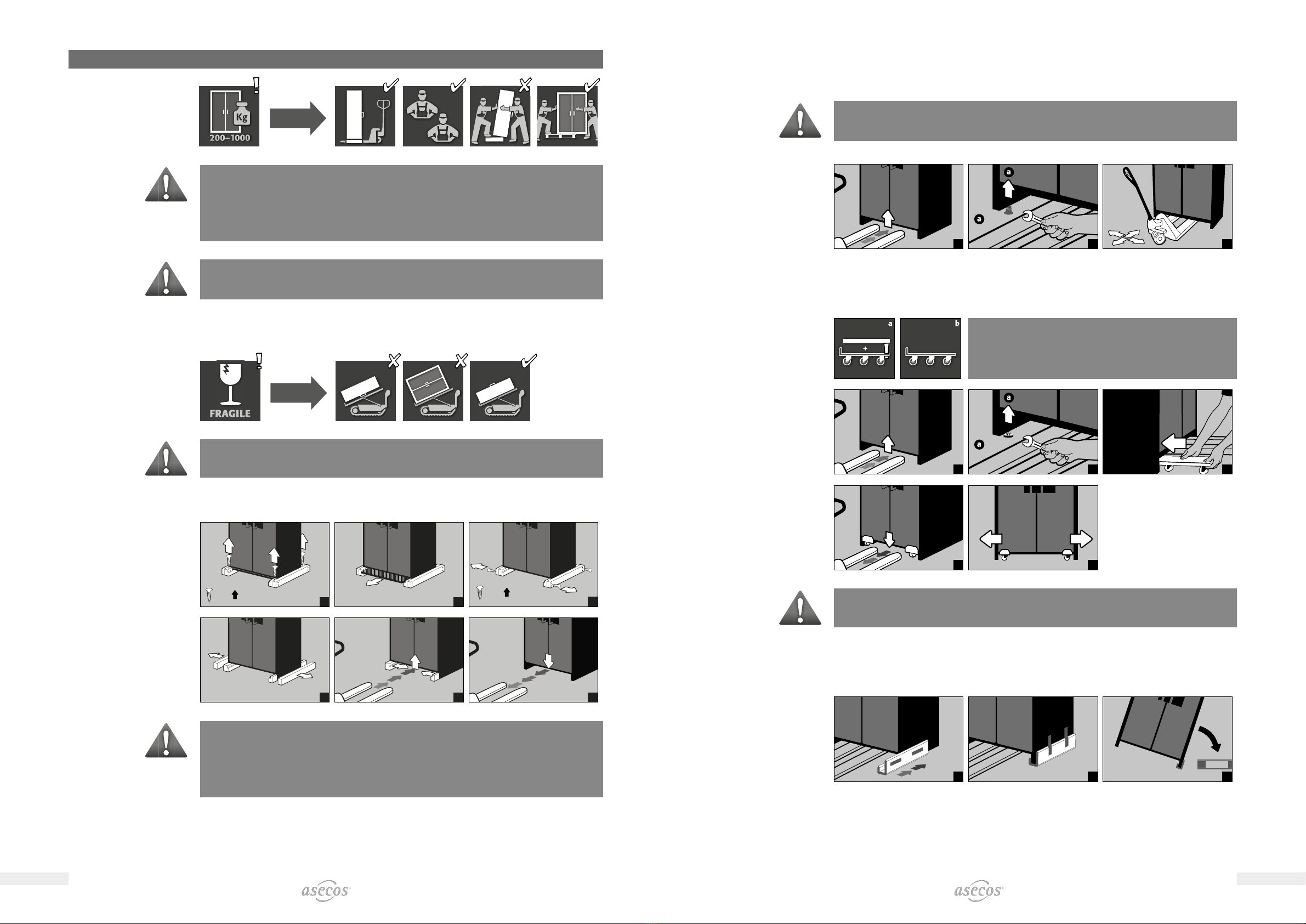

2. TRANSPORT ................................................................. 6

2.1. Tilting the cabinet .............................................. 6

2.2. Dismantling of the transport packaging ............................. 6

2.3. In-plant transport ............................................... 7

2.4. Q-Mover ...................................................... 7

2.5. Titling onto the side wall ......................................... 7

3. INSTALLATION ............................................................... 8

3.1. Alignment of the cabinets ........................................ 8

3.2. Commissioning................................................. 8

4. CLOSING .................................................................... 8

5. INTERIOR EQUIPMENT ........................................................ 9

5.1. Bottom collecting sump.......................................... 9

5.2. Grids / Shelves with power socket strips ............................ 9

5.3. Total power rating of the power socket strips ........................ 9

6. STORAGE .................................................................. 10

6.1. Notes on storage and charging ................................... 10

7. VENTILATION ............................................................... 10

7.1. Extraction unit .................................................11

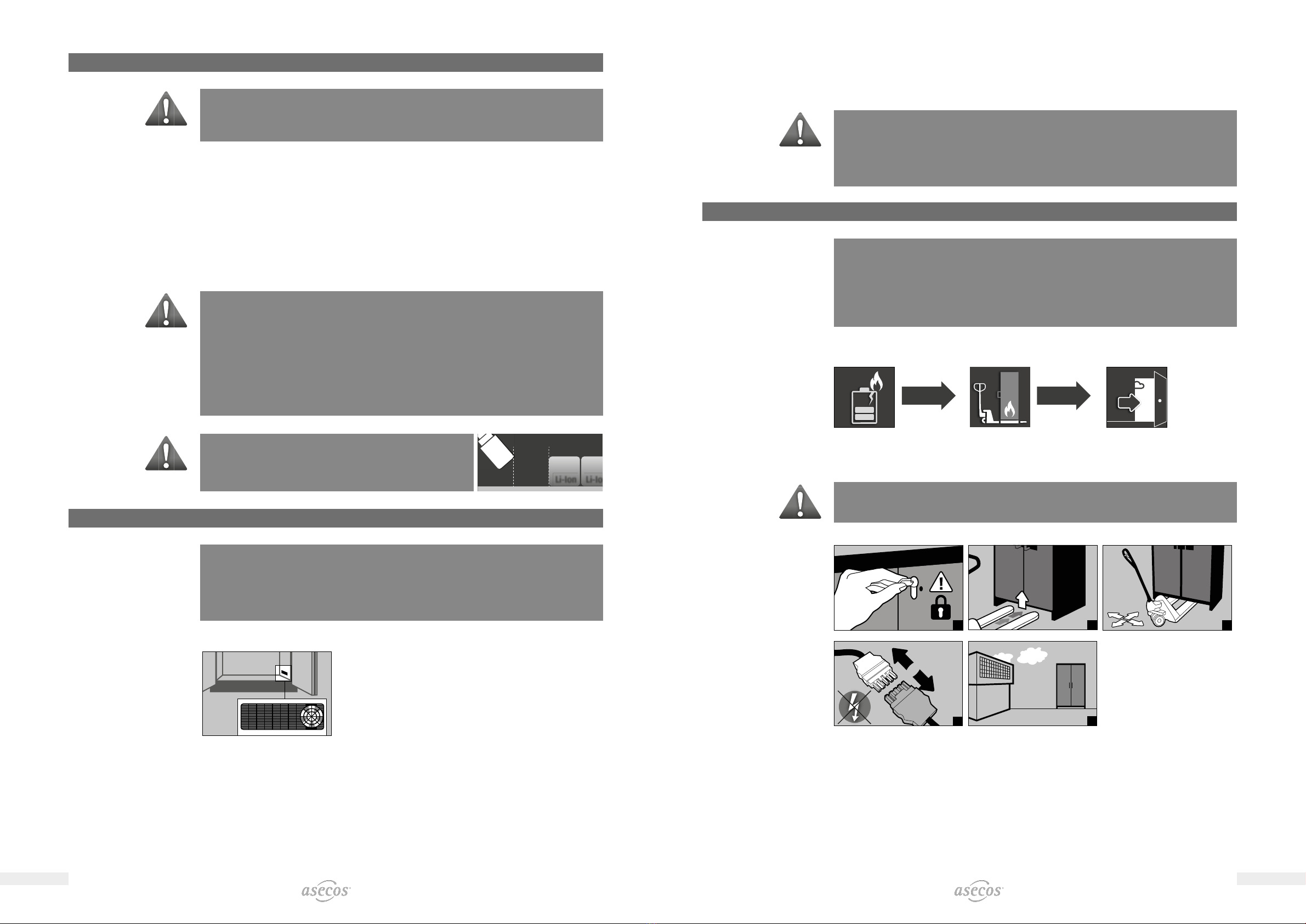

8. BATTERY FIRE • FIRE • DISPOSAL ................................................11

8.1. Fire inside the cabinet (battery fire)................................11

8.2. Opening the cabinet after the fire. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

8.3. Disposal ..................................................... 12

9. SAFETY CHECKS............................................................. 12

9.1. All models .................................................... 12

9.2. IO90.195.120.K3.WDC .......................................... 12

9.3. IO90.195.060.K9.WDC .......................................... 12

9.4. Contact ...................................................... 12

SPECIFIC NOTES

10. IO90.195.120.K3.WDC ........................................................ 13

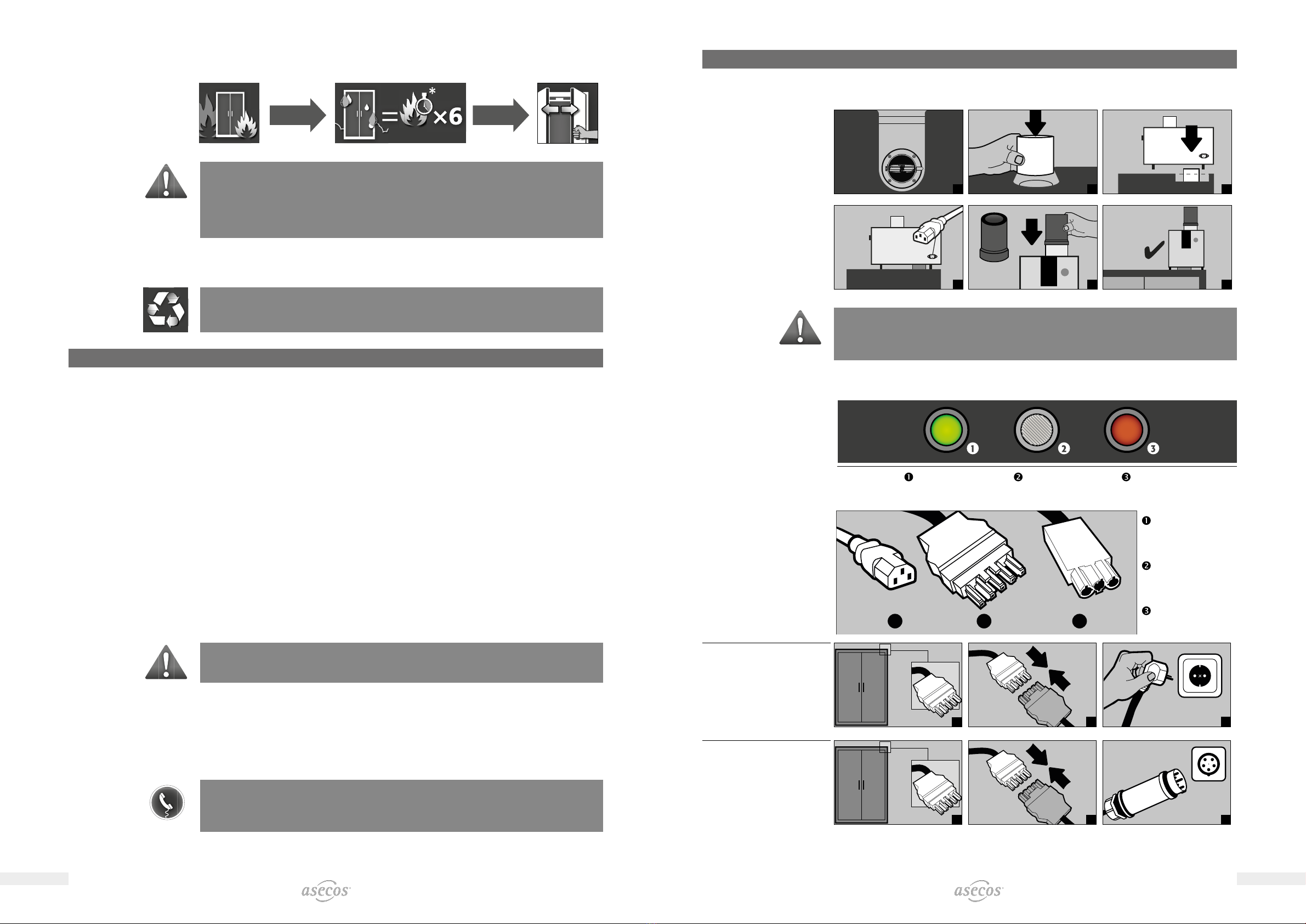

10.1. Installation of the extraction unit ................................. 13

10.2. Connection to the power supply.................................. 13

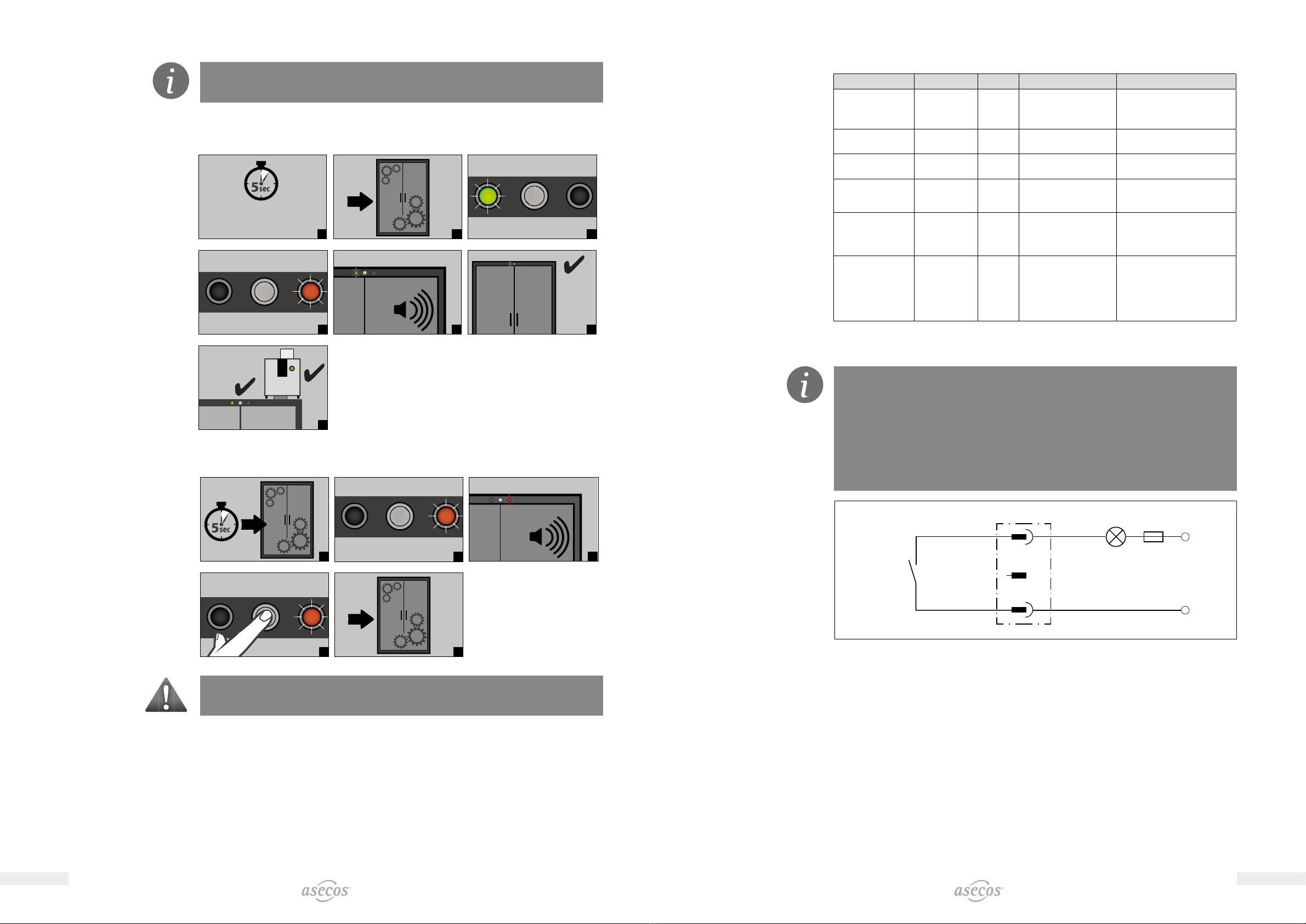

10.3. Self test ...................................................... 14

10.4. Error during self-test ........................................... 14

10.5. Error and alarm overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

10.6. Potential-free alarm contact ..................................... 15

10.7. Warning/fire suppression system ................................. 16

10.8. Warning message .............................................. 16

10.9. Alarm stage 1 ................................................. 17

10.10. Alarm stage 2 ................................................. 17

10.11. False alarm of the smoke detector ................................ 17

11. IO90.195.060.K9.WDC........................................................ 18

11.1. Connection to the power supply.................................. 18

11.2. Error and alarm overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

11.3. Potential-free alarm contact ..................................... 19

11.4. Smoke detector – false alarm .................................... 19

11.5. Smoke detector – battery change ................................. 19

11.6. Smoke detector – maintenance .................................. 20

12. TECHNICAL DATA............................................................ 21

13. TECHNICAL DRAWING........................................................ 21