4

EN

1. NOTES • GUIDELINES • GUARANTEE ............................................. 5

1.1. General safety notes ............................................ 5

1.2. Guarantee ..................................................... 5

1.3. Cabinet Details ................................................. 5

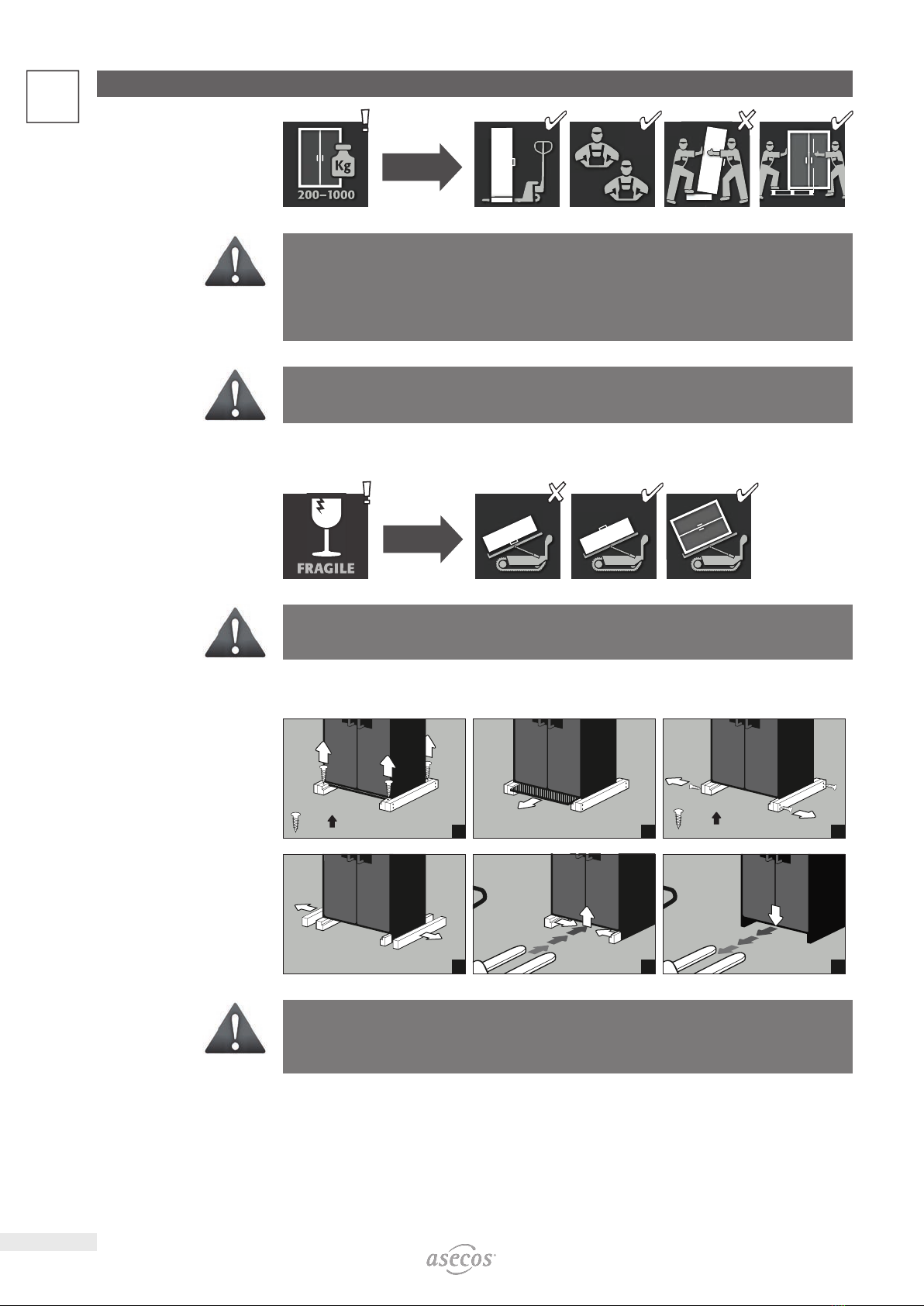

2. TRANSPORT ................................................................. 6

2.1. Tilting the cabinet .............................................. 6

2.2. Dismantling of the transport packaging ............................. 6

2.3. In-plant transport ............................................... 6

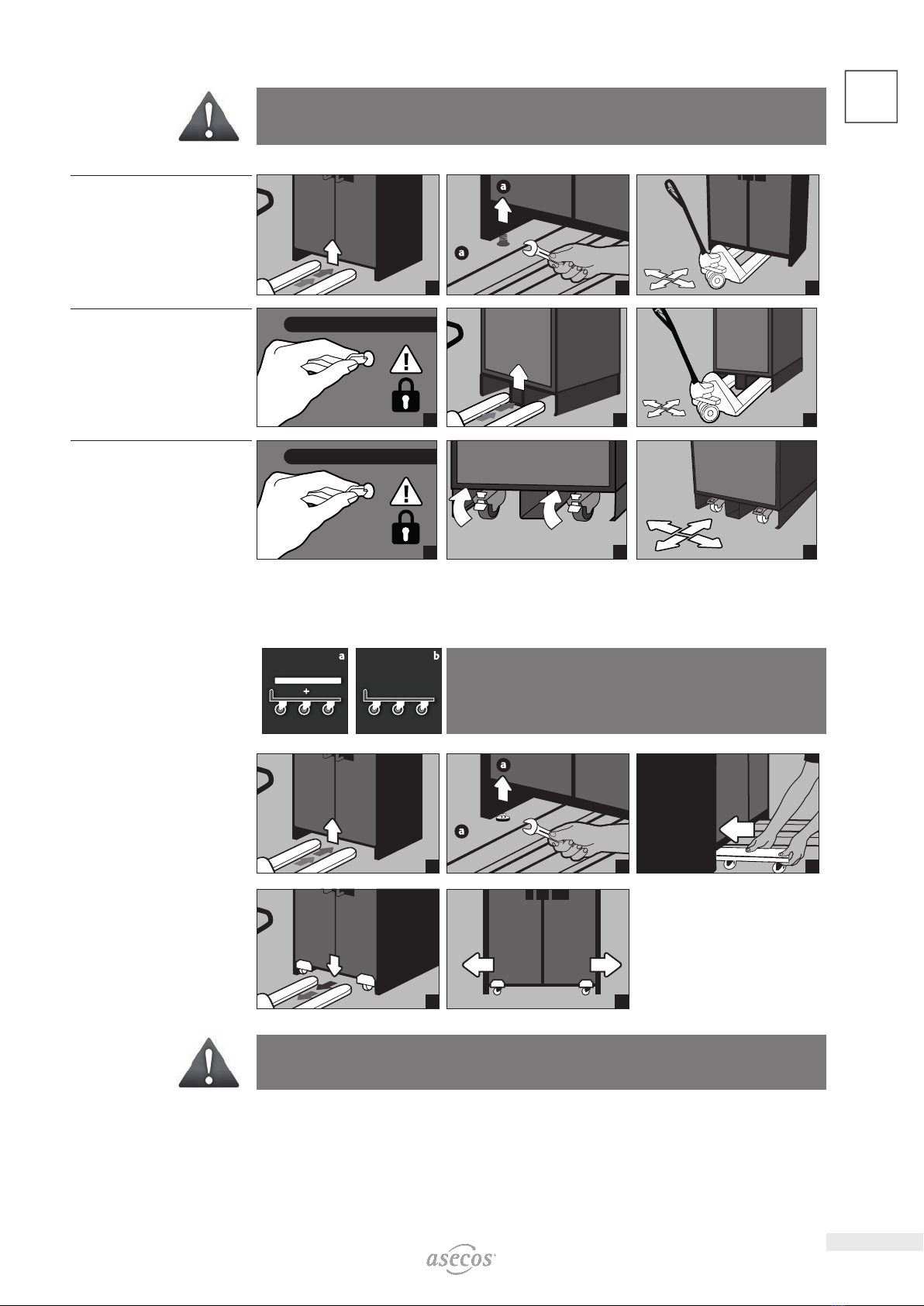

2.4. Q-Mover ...................................................... 7

2.5. Titling onto the side wall ......................................... 7

3. INSTALLATION ............................................................... 8

3.1. Alignment Of The Cabinets ....................................... 8

3.2. Commissioning ................................................. 8

4. CLOSING .................................................................... 8

4.1. In general ..................................................... 8

4.2. Locker System .................................................. 9

5. INTERIOR FITTINGS ........................................................... 9

5.1. Bottom collecting sump .......................................... 9

5.2. Storage levels with power socket strips ............................ 10

5.3. Total power rating of the power socket strips ....................... 10

6. STORAGE .................................................................. 10

6.1. Notes on storage and charging ................................... 10

7. VENTILATION ................................................................11

7.1. Extraction unit (IO90.195.120.K3.WDC) .............................11

7.2. Fan (IO90.078.059.057.U9.S) .....................................11

8. BATTERY FIRE • EVENT OF FIRE • DISPOSAL .......................................11

8.1. Fire inside the cabinet (battery fire) ............................... 12

8.2. Opening the cabinet after the fire. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

8.3. Disposal ..................................................... 13

9. SAFETY CHECKS ............................................................. 14

9.1. All Models .................................................... 14

9.2. IO90.195.120.K3.WDC .......................................... 14

9.3. IO90.195.060.K9.WDC - IO90.078.059.057.U9.S ..................... 14

9.4. IO90.195.060.L8.WDC .......................................... 14

9.5. Contact ...................................................... 14

10. TECHNICAL DATA ............................................................ 15

11. TECHNICAL DRAWING ........................................................ 15

12. IO90.195.120.K3.WDC ........................................................ 16

12.1. Installation of the extraction unit ................................. 16

12.2. Connection to the power supply .................................. 16

12.3. Self-Test ...................................................... 17

12.4. Error during self-test ........................................... 17

12.5. Error and alarm overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

12.6. Potential-free alarm contact ..................................... 18

12.7. Warning/fire suppression system ................................. 19

12.8. Warning message .............................................. 19

12.9. Alarm stage 1 ................................................. 19

12.10. Alarm stage 2 ................................................. 20

13. IO90.195.060.K9.WDC ........................................................22

13.1. Connection to the power supply ..................................22

13.2. Error and alarm overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

13.3. Potential-free alarm contact .....................................22

13.4. False alarm of the smoke detector ................................ 23

13.5. Smoke detector - battery change ................................. 23

13.6. Smoke detector - maintenance ...................................23

14. IO90.195.060.L8.WDC ........................................................ 24

14.1. Connection to the power supply .................................. 24

14.2. Error and alarm overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

14.3. Potential-free alarm contact ..................................... 25

15. IO90.078.059.057.U9.S ....................................................... 26

15.1. Connection to the power supply .................................. 26

15.2. Error and alarm overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

15.3. Potential-free alarm contact ..................................... 26

15.4. False alarm of the smoke detector ................................ 27

15.5. Smoke detector - battery change ................................. 27

15.6. Smoke detector - maintenance ................................... 27