6 76 7

EN

2. DISPOSAL

The models can be disposed of once they have

been dismantled and the materials sorted. They

are free from materials that have to be dispo-

sed of as special waste.

3. SAFETY CHECKS

The cabinets are designed and built in such a way that no significant servicing is required. If

safety-relevant damage (such as to the seals in acid and alkali cabinets) is found, the operator

must ensure that original parts are used to restore the cabin to good order before it is used again.

In order to check the evacuation, take a light piece of fluff or a smoke tube, and check that you

can observe a draught inside the cabinet in the area of the outlet opening (on the right of the

cabinet or at the rear wall).

In addition, we recommend that you carry out a daily and monthly functional check:

Daily functional check

• applies to the spill containment sumps (collect and remove any leakages)

Monthly functional check

• perfect function of the doors

• regular filter check (see point 8)

In case of damage please contact your dealer in order to have the cabinet repaired using original

spare parts. The cabinets can be cleaned with a mild household cleaner and a soft cloth.

CONTACT:

In the case of defects or complaints about our products (within and also after the

warranty period), and for requesting safety checks or taking out a service contract,

please contact our service hotline on:

1. NOTES • GUIDELINES • GUARANTEE

1.1. GENERAL SAFETY NOTES

• Observe applicable statutes and regulations, and the notes in these operating instructions, when

handling hazardous materials.

• Work on the electrical system is to be carried out only with the power turned off and only by

qualified electricians – refer here to the regulations of the local electricity supply company.

• The on-site installation conditions are to be observed (e.g. bolting the cabinets to the building).

• The instructions of the supervisory engineering department must be followed.

• Observe accident prevention regulations and workplace ordinance.

• Ensure that necessary safety checks are only carried out by authorised staff using original spare parts.

• Only use the cabinet after having been properly instructed; access is to be forbidden to

unauthorised persons.

• The pivoting area of the doors is to be kept free at all times; doors/drawers are to be kept closed.

• By assigning trained/authorised technical personnel you can prevent the malfunctions, damage

and corrosion damage that result from inappropriate transport.

• Observe the upper limits for stored quantities, loading etc.

• Containers with a volume larger than that of the spill containment sump may not be placed

inside the cabinet; spilt hazardous materials are to be collected immediately and removed.

• Vessels containing aggressive chemicals (acids/alkalis) are to be kept in special cabinets for acids and

alkalis or on shelves for acids and alkalis as well as in cabinets with metal-free interior equipment.

• Sufficient technical ventilation must be ensured.

• Before storing such materials, check that the cabinet's surface is resistant to the chemicals.

• The storage of corrosive liquids or gases can affect the function of the shut-off equipment for the

air supply and exhaust.

• Before the initial commissioning, the safety storage cabinet is to be examined by the user for

possible damage.

1.2. GUARANTEE

The guarantee for this product is agreed between you (the customer) and your dealer

(the seller). As the manufacturer, asecos guarantees the products listed in the operating instruc-

tions for a period of 24 months from the date of delivery. All model safety equipment are subject

to a compulsory annual inspection by specialised staff authorised by the manufacturer. Otherwise

the customer’s guarantee claim against the manufacturer expires.

PLEASE NOTE!

Only the original asecos accessories and spare parts are accepted!

Otherwise the costumer's guarantee claim against the manufacturer expires and

asecos assumes no liability for potential damage!

1.3. CABINET DETAILS

A complete overview of the models can be found at the start of the operating instructions.

Cabinet data Logbook (included with the cabinet)

Technical drawing Appendix 2

Technical data Table in Appendix 1

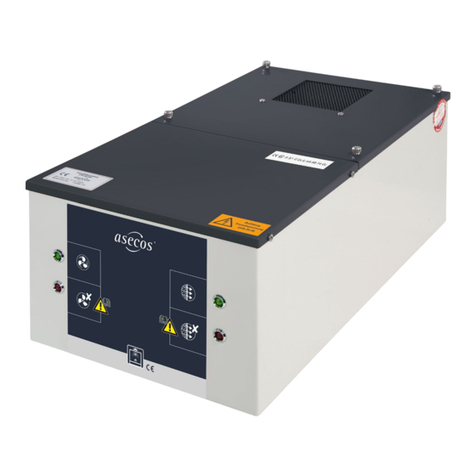

CX-LINE

secure storage of chemicals in accordance with regulations (not for the storage of inflammable liquids)

SLX-LINE

secure storage of aggressive liquids in accordance with regulations (not for the storage of inflam-

mable liquids)