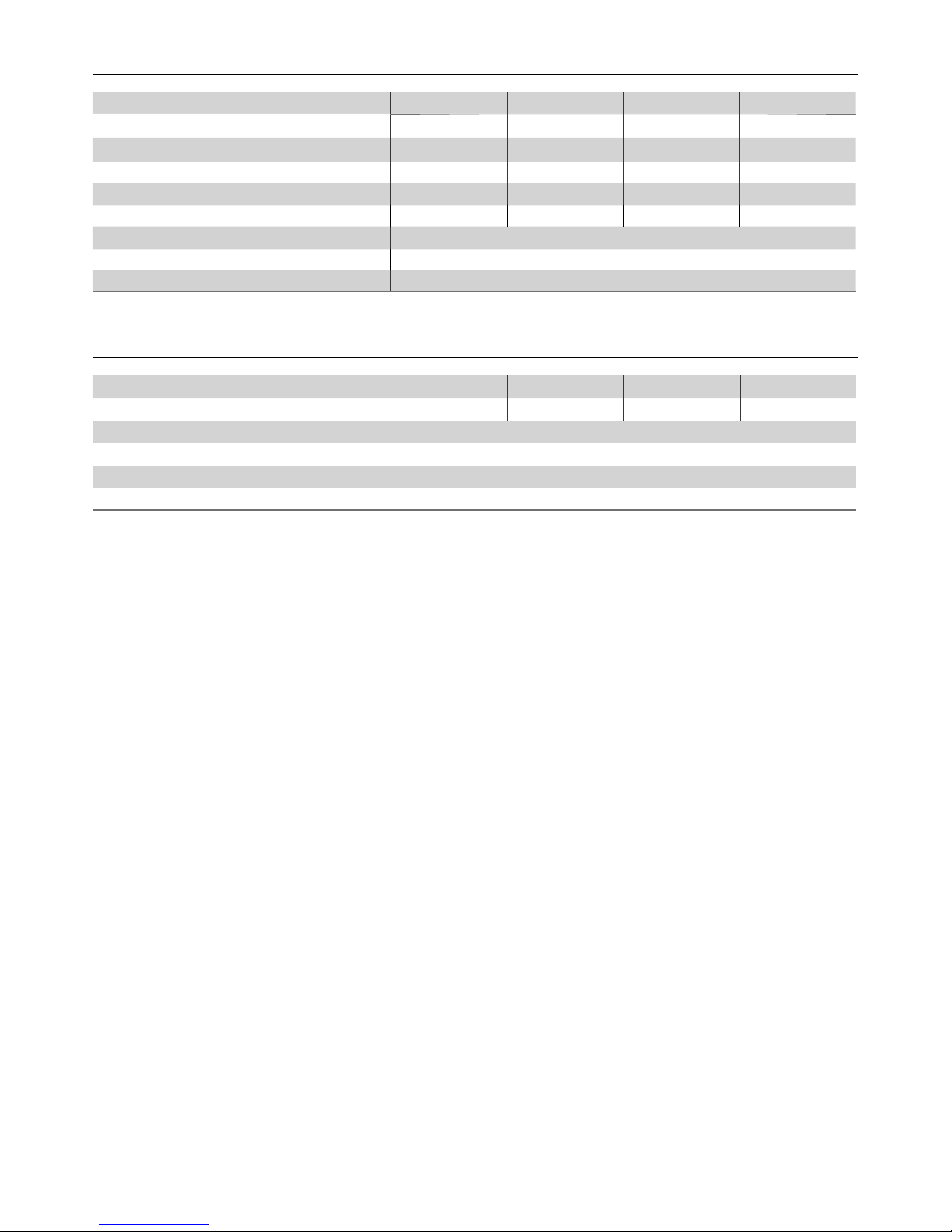

Coffee and Vending machines

Combi Steamers / Self-Cooking Systems / Steam Cookers / Ovens

Direct Injection

°KH °Clarke

(GB) PPM °FH

By-

pass-

levels

capacity in liters

SMLXL

< 6 8 107 11 0 1'500 2'500 4'660 6'670

7 9 125 13 0 1'290 2'140 4'000 5'710

8 10 143 14 0 1'130 1'880 3'500 5'000

9 11 161 16 0 1'000 1'670 3'110 4'440

10 13 179 18 0 900 1'500 2'800 4'000

11 14 196 20 0 820 1'360 2'550 3'640

12 15 214 21 0 750 1'250 2'330 3'330

13 16 232 23 0 690 1'150 2'150 3'080

14 18 250 25 0 640 1'070 2'000 2'860

15 19 268 27 0 600 1'000 1'870 2'670

16 20 286 29 0 560 940 1'750 2'500

17 21 304 30 0 530 880 1'650 2'350

19 24 339 34 0 470 790 1'470 2'100

21 26 375 38 0 430 710 1'330 1'900

23 29 411 41 0 390 650 1'220 1'740

26 33 464 46 0 350 580 1'070 1'540

29 36 518 52 0 310 520 960 1'380

33 41 589 59 0 270 450 850 1'210

38 48 679 68 0 240 390 730 1'050

Capacities are intended as guidelines and can vary according the machine typ.

Please contact us for recommendations.

Boiler System

°KH °Clarke

(GB) PPM °FH

By-

pass-

levels

capacity in liters

SM L XL

< 6 8 107 11 3 2'140 3'570 6'670 9'520

7 9 125 13 3 1'840 3'060 5'710 8'160

8 10 143 14 2 1'410 2'340 4'370 6'250

9 11 161 16 2 1'250 2'080 3'890 5'550

10 13 179 18 2 1'130 1'880 3'500 5'000

11 14 196 20 2 1'020 1'700 3'180 4'550

12 15 214 21 2 940 1'560 2'920 4'170

13 16 232 23 2 870 1'440 2'690 3'850

14 18 250 25 2 800 1'340 2'500 3'570

15 19 268 27 2 750 1'250 2'330 3'330

16 20 286 29 2 700 1'170 2'190 3'120

17 21 304 30 2 660 1'100 2'060 2'940

19 24 339 34 2 590 990 1'840 2'630

21 26 375 38 1 480 790 1'480 2'120

23 29 411 41 1 430 720 1'350 1'930

26 33 464 46 1 380 640 1'200 1'710

29 36 518 52 1 340 570 1'070 1'530

33 41 589 59 1 300 510 940 1'340

38 48 679 68 1 260 440 820 1'170

Capacities are intended as guidelines and can vary according the machine typ.

Please contact us for recommendations.

Coffee-Espresso

°KH °Clarke

(GB) PPM °FH

By-

pass-

levels

capacity in liters

SML XL

< 6 8 107 11 5 3'000 5'000 9'200 13'200

7 9 125 13 5 2'570 4'280 7'890 11'310

8 10 143 14 4 1'870 3'120 5'750 8'250

9 11 161 16 4 1'670 2'780 5'110 7'330

10 13 179 18 4 1'500 2'500 4'600 6'600

11 14 196 20 4 1'360 2'270 4'180 6'000

12 15 214 21 3 1'070 1'790 3'290 4'710

13 16 232 23 3 990 1'650 3'030 4'350

14 18 250 25 3 920 1'530 2'820 4'040

15 19 268 27 3 860 1'430 2'630 3'770

16 20 286 29 3 800 1'340 2'470 3'540

17 21 304 30 3 760 1'260 2'320 3'330

19 24 339 34 3 680 1'130 2'070 2'980

21 26 375 38 2 540 890 1'640 2'360

23 29 411 41 2 490 810 1'500 2'150

26 33 464 46 2 430 720 1'330 1'900

29 36 518 52 2 390 650 1'190 1'710

33 41 589 59 2 340 570 1'040 1'500

38 48 679 68 2 300 490 910 1'300

The COFFEE-ESPRESSO application describes the production of hot drinks with

steam operation. The stated capacities are intended as guidelines for single cup

dispense. The capacities may vary according to dispensed volume and machine

type. Please contact us for recommendations.

Vending

°KH °Clarke

(GB) PPM °FH

By-

pass-

levels

capacity in liters

SM L XL

< 6 8 107 11 6 3'540 6'250 11'670 16'670

7 9 125 13 6 3'040 5'360 10'000 14'280

8 10 143 14 5 2'120 3'750 7'000 10'000

9 11 161 16 5 1'890 3'330 6'220 8'890

10 13 179 18 5 1'700 3'000 5'600 8'000

11 14 196 20 5 1'550 2'730 5'090 7'270

12 15 214 21 4 1'180 2'080 3'890 5'550

13 16 232 23 4 1'090 1'920 3'590 5'130

14 18 250 25 4 1'010 1'790 3'330 4'760

15 19 268 27 4 940 1'670 3'110 4'440

16 20 286 29 4 880 1'560 2'920 4'170

17 21 304 30 4 830 1'470 2'750 3'920

19 24 339 34 4 750 1'320 2'460 3'510

21 26 375 38 3 580 1'020 1'900 2'720

23 29 411 41 3 530 930 1'740 2'480

26 33 464 46 3 470 820 1'540 2'200

29 36 518 52 3 420 740 1'380 1'970

33 41 589 59 3 370 650 1'210 1'730

38 48 679 68 3 320 560 1'050 1'310

The VENDING application describes the production of hot drinks without steam

operation. The stated capacities are intended as guidelines for single cup

dispense. The capacities may vary according to dispensed volume and machine

type. Please contact us for recommendations.

10a. Settings and Capacities in liters