9

EN

Ser 4

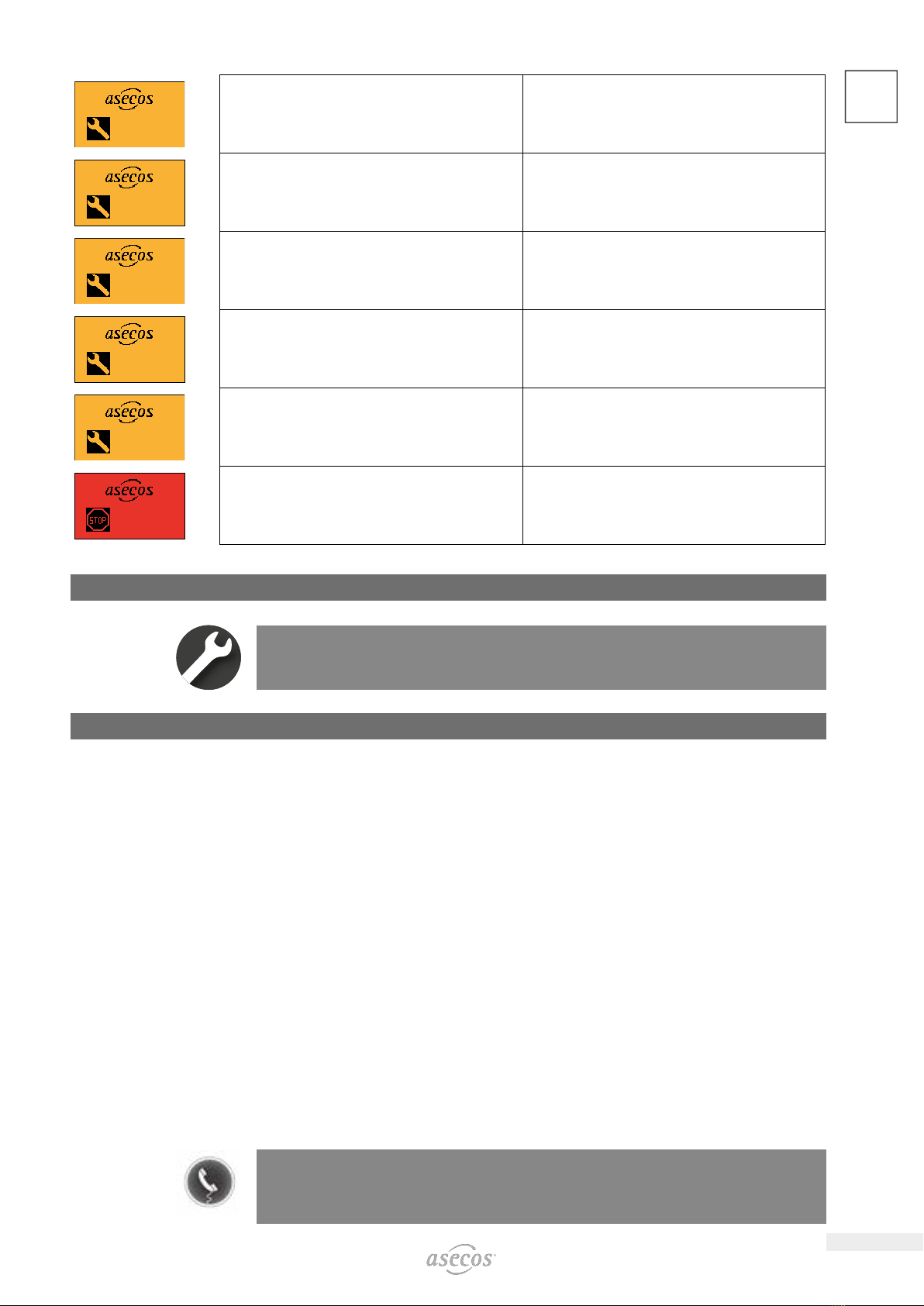

Running time of the filter sensor longer than 54 months.

Sensor drift and thus safe operation can no longer be guaranteed. The

sensor must be replaced.

Please contact your responsible specialist dealer

or to our service hotline 01805 - 92 20 9

F 1

Dierential pressure sensor error Please contact your responsible specialist dealer

or to our service hotline 01805 - 92 20 9

F 2

Error temperature/humidity sensor Please contact your responsible specialist dealer

or to our service hotline 01805 - 92 20 9

F 3

Filter sensor defective Please contact your responsible specialist dealer

or to our service hotline 01805 - 92 20 9

F 4

Fan defective (blocked) Please contact your responsible specialist dealer

or to our service hotline 01805 - 92 20 9

F 7

Self test error

Display F7 alternating with the respective error F1 to F4

Please contact your responsible specialist dealer

or to our service hotline 01805 - 92 20 9

14 ct/called minute from the Deutsche Telekom AG fixed network, from mobile phones a maximum of 42 ct/minute.

6. REPAIRS

ATTENTION

Repairs are only to be carried out by specialists specifically trained for this.

Given damage the appliance is to be repaired or replaced by the manufacturer.

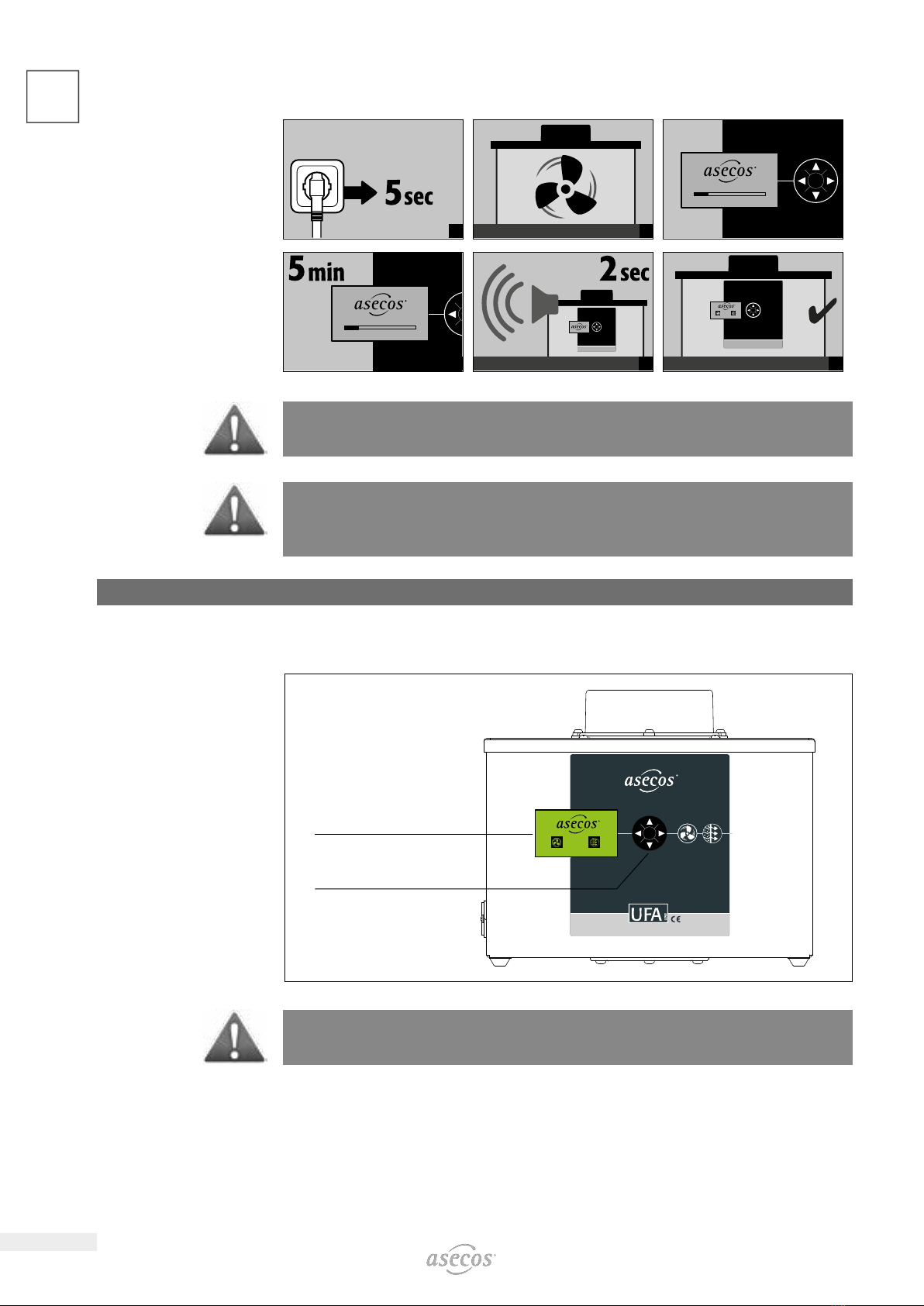

7. FUNCTIONAL CHECK • MAINTENANCE • CARE

To ensure safety, the recirculation filter attachment should be serviced at least once a year and its function

checked by a specialist. At the same time, the built-in filter unit must be replaced at least once a year, and

immediately when the saturation limit is reached.

The functionality is checked electronically by the integrated ventilation and filter saturation monitoring, so that

a function check of the recirculation filter attachment is carried out permanently during operation. The activat-

ed charcoal main filter of the recirculation filter attachment must be replaced with a new filter at short notice

if the corresponding maintenance indicator (red screen) is shown. The filter can only be replaced by one of

our trained service technicians and must be requested promptly on the service hotline. Filter replacement by

asecos service personnel ensures that the contaminated activated carbon is fed into a defined disposal chain.

7.1. SENSORS AND MONITORING ELECTRONICS

The UFA contains sensitive sensors and complex monitoring electronics. The device must be designed as a

“continuous 24/7" and was also designed for this purpose. The sensitive gas sensor system in particular is

heavily stressed by continuous operation and, according to experience, can deliver unreliable measurement

results after a certain period of operation (drift) after approx. 40,000 operating hours.

The UFA can then no longer be used safely (possible monitoring errors).

In this case, a visual warning is given. In this case, please contact the customer service for replacement of the

sensor unit.

7.2. CLEANING

For external cleaning of the recirculating air filter attachment, please use common, mild household cleaners

and a soft cloth. Disconnect your recirculating air filter attachment from the mains by unplugging

the power cable before cleaning! Make sure that no moisture gets into the inside of the recircu-

lating air filter attachment during cleaning.

CONTACT:

In the case of defects or complaints about our products (within and also after the warranty period), and for

requesting safety checks or taking out a service contract, please contact our service hotline on:

Tel: +44 1785 22 70-90 info@asecos.co.uk