Bag Replacement

The pressure differential across the bag will remain fairly constant

until the bag is approximately 80% blinded off. It is recommended that

the bag be changed when the pressure differential reaches 15 psi.

However, this figure can vary with the type of filter bag. The bag

manufacturer’s data should be consulted to determine the actual

pressure drop for replacement.

WARNING:Review all precautions specific to the handling of the

fluid being filtered before changing the filter bag. A filter bag that

has been used with a hazardous liquid may contain residual

amounts of this material and should be handled with the same

safeguards that would be used in handling any hazardous and/or

toxic material i.e. gloves, respirators, protective eyewear, etc.

Filter bags should be disposed of in accordance with federal, state

or local laws and requirements. Failure to follow precautions may

result in injury.

1. Close isolation valves to the filter.

2. Drain sump. (See WARNING above)

NOTE: If bag has not been changed on a timely basis it may not

drain. If necessary, the liquid contents of the used bag can be

poured into the replacement bag to be filtered.

3. Unscrew sump from cap. Sump will unscrew counter-clockwise

(when viewed from bottom).

CAUTION: Support sump at base while unscrewing to prevent

dropping and possibly damaging the sump or drain valve.

4. Remove basket assembly from sump. (See WARNING above)

5. Remove bag from basket.

6. Remove o-ring from groove in the sump and wipe groove and O-ring

clean. Relubricate o-ring with silicone grease. Insert o-ring in place

and press into groove.

NOTE: This step is important to ensure a proper housing seal. Make

certain the o-ring is seated level in the groove.

7. Insert new bag into the basket. Form the bag to the contours of the

basket, making sure that the bag extends fully to the bottom of the

basket.

NOTE: Make sure the filter bag overlaps the bag collar to insure a

proper seal when the filter housing is closed.

8. Screw the sump onto the cap and hand-tighten securely. Do not

over-tighten.

Troubleshooting

Leaks

1.Check the o-ring for dirt, cuts, or swelling. Replace o-ring if neces-

sary.

2. Make sure housing is closed properly. Hand-tighten securely. Do

not over-tighten.

3. Check all threaded connections and rethread as needed.

4. Check to see if the filter bag is dirty and blinded off. (See

WARNING under Bag Replacement) If this is the case, replace bag

according to instructions.

Poor Filtration Results

1. Check to make sure the filter bag is properly seated in the support

basket. (See WARNING under Bag Replacement) The bag should

extend fully to the bottom of the basket and the top should overlap

the sealing collar.

2. Check for rips or tears in the filter bag.

QUESTIONS?

Call our Technical Support Department at 1-800-861-8758

Page 3

Bag Selection

The Pentek Bag Filter System is designed for use with Pentek filter

bags. However, the housing may accept some filter bags from other

manufacturers. The unit is designed to accept a standard 4-inch

FILTER SPECIALISTS, INC. (FSI) POLYLOC filter bag.

Other 4-inch filter bags may work if they meet the following criteria:

1. Filter bag length equals the depth of the filter basket plus 1-inch.

2. The maximum allowable thickness of the filter bag at the

sealingsurface is .080 inches.

3. The minimum allowable thickness of the filter bag at the sealing-

surface is .040 inches.

NOTE: The Pentek Bag Filter System may not be compatible with filter

bags using reinforcing rings or snap bands.

Start-up

1. Open the inlet valve. It is recommended that the inlet valve be

opened before the outlet valve to prevent any backflow.

2. Vent trapped air from the system before opening the outlet valve.

3. Open the outlet valve.

Precautions

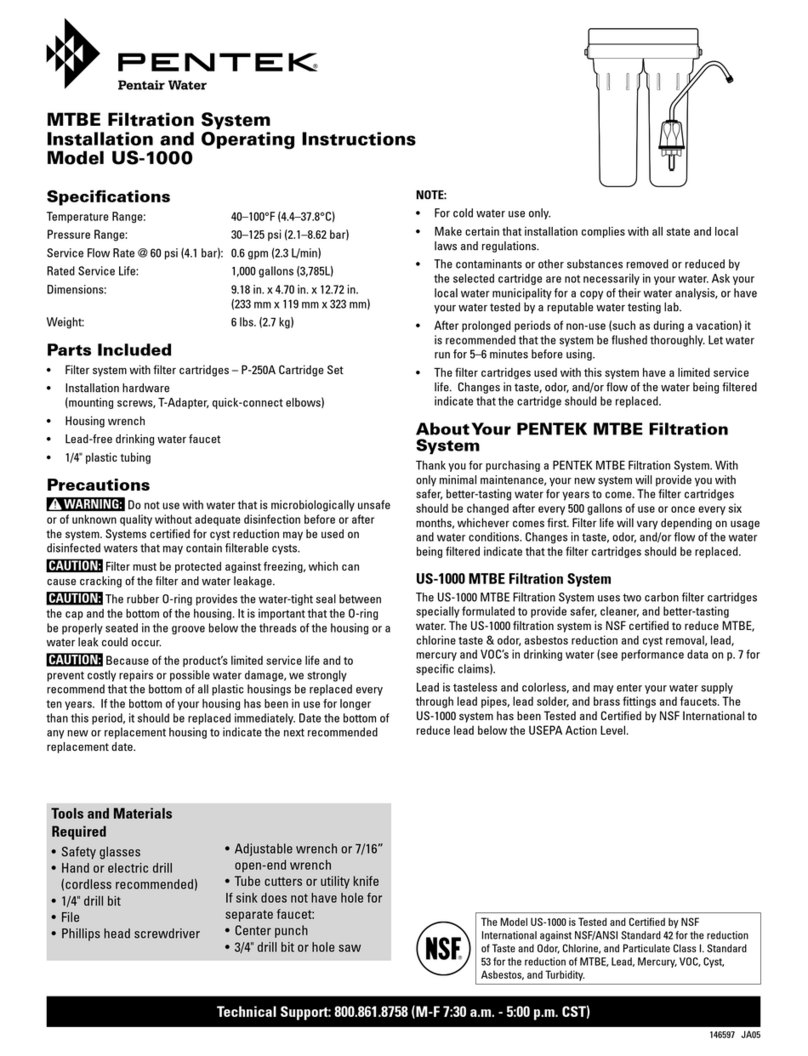

WARNING: For drinking water applications, do not use with water

that is microbiologically unsafe or of unknown quality without ade-

quate disinfection before or after the system.

CAUTION: Filter must be protected against freezing (when used with

aqueous solutions), which can cause cracking of the filter and

water leakage.

CAUTION: Because of the product’s limited service life and to pre-

vent costly repairs or possible water damage, we strongly recom-

mend that the bottom of all plastic housings be replaced every ten

years. If the bottom of your housing has been in use for longer than

this period, it should be replaced immediately. Date the bottom of

any new or replacement housing to indicate the next recommended

replacement date.

NOTE:

•Make certain that installation complies with all state and local

laws and regulations.

•Do not use wicking or sealer for fitting connections into the cap of

the filter. Teflon®tape is recommended for this purpose.

•Do not install where system will be exposed to direct sunlight.

•Allow a minimum of 3-inches clearance under the filter or optional

sump stand to facilitate filter changes.

Installation

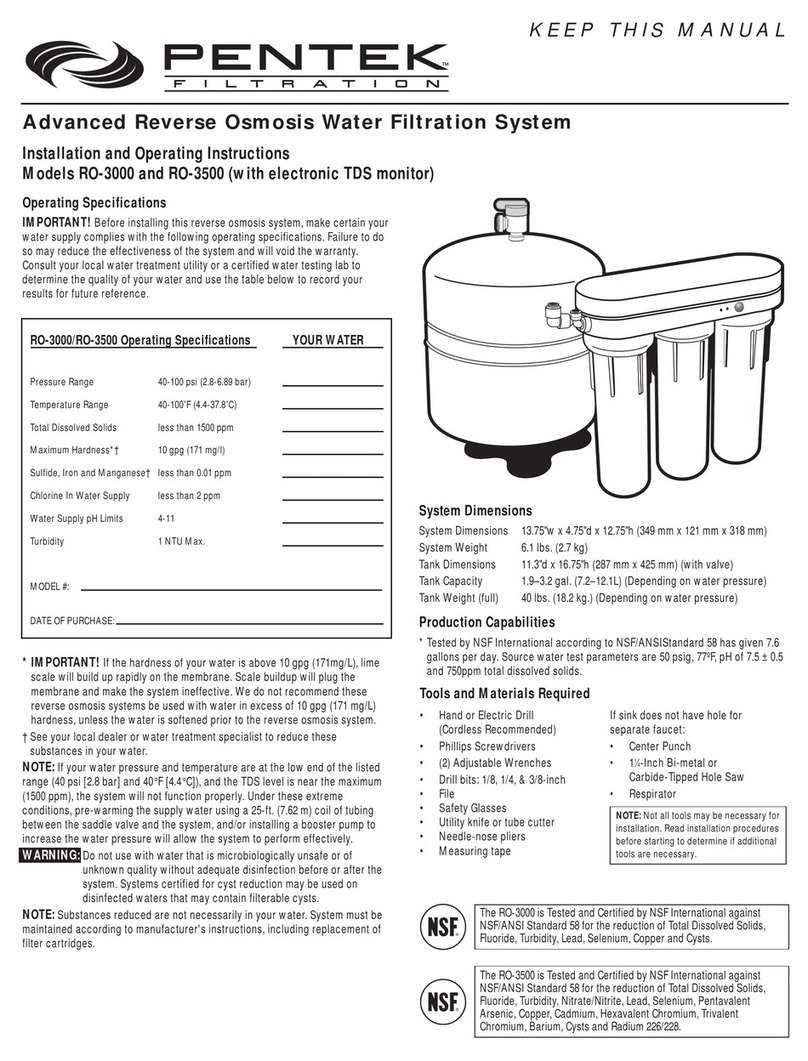

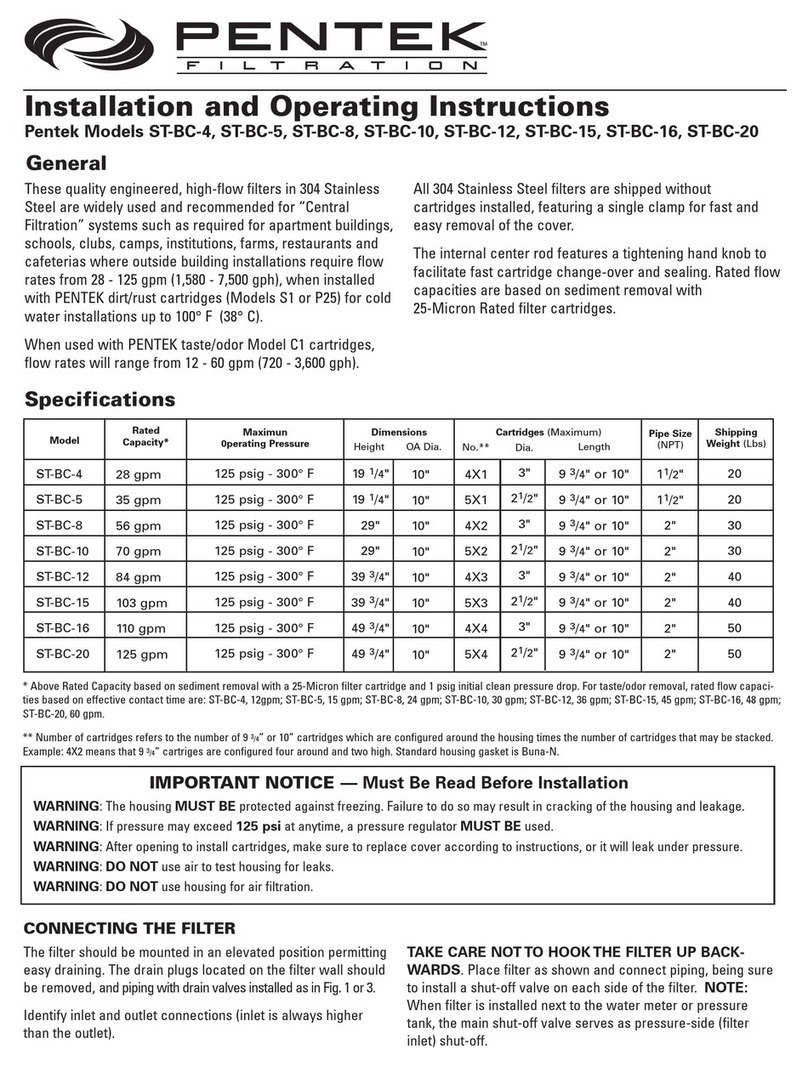

1. Before installing, verify that the materials of construction of the

Pentek Bag Filter System are compatible with the fluid being

filtered.

2. The location of the filter should include the following

considerations: (1) adequate space for ease of changing the filter

bag, (2) drainage or containment to collect drained or spilled

liquid, and (3) proper ventilation, if required.

3. When installing the system, include isolation valves for the filter

and support for the filter housing. Use caution when applying heat

near the filter housing. It is best to weld or sweat all fittings before

assembly to the filter. The filter head may be mounted to the

filter support using 5/16 inch X 71

/

4inch lag bolts. The bolt spacing

is 3-inch on center, and the bolt circle is 21

/

8inch. (See figure at

right.)

4.The filter must be installed in the vertical position with the

inlet/outlet ports at the top. Flow through the housing is inline. Note

the inlet and outlet ports when connecting piping.

5. The filter housing is equipped with a 1/4 inch NPT gauge port on

the outlet for installation of a pressure gauge (included) and a 3/8-

inch NPT drain port at the base of the sump (3/8 inch NPT ball

valve supplied). The gauge or valve should be installed using

Teflon tape as a thread sealant.

Page 2